Novel high-strength furniture board and preparation method and application thereof

A high-strength, board technology, applied in the field of furniture materials, can solve problems such as poor long-term bearing capacity, heavy pollution, and health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

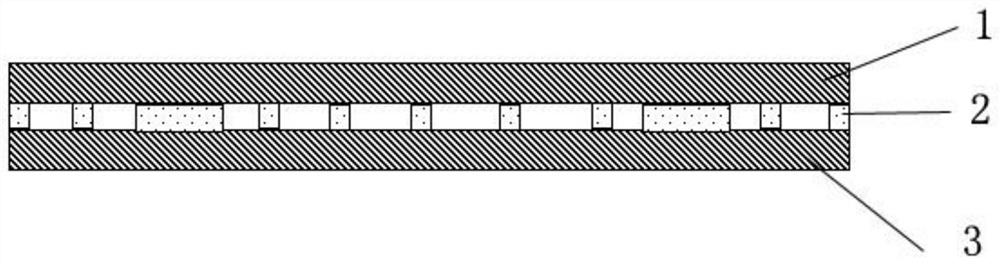

Image

Examples

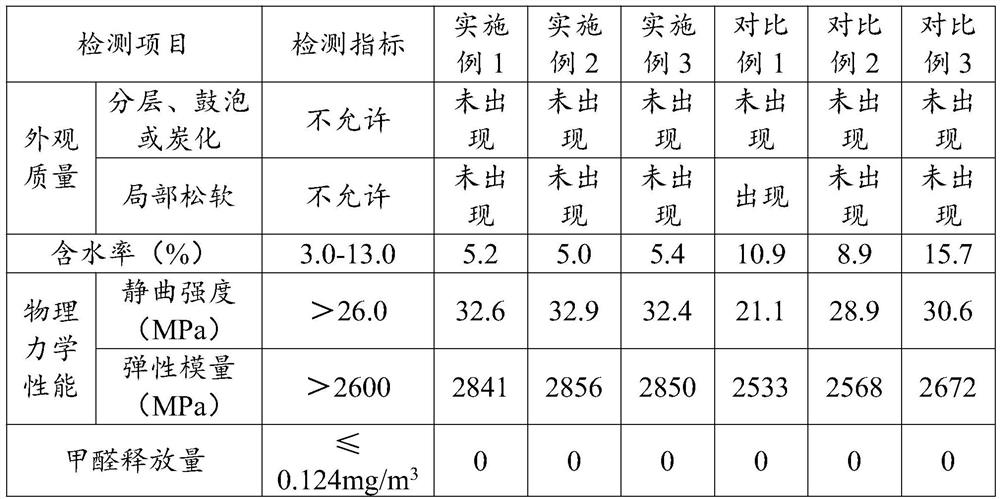

Embodiment 1

[0047] New high-strength furniture boards, including the following raw materials: 100kg of wood fiber, 100kg of ordinary Portland cement, 70kg of PVC resin powder, 50kg of light calcium carbonate, 5kg of ferric chloride, 5kg of phenolic resin glue, 1kg of nano-zinc oxide, anti- Oxygen agent 10101kg, PE wax 0.5kg and stearic acid 0.5kg;

[0048] The preparation method of the above-mentioned novel high-strength furniture board specifically comprises the following steps:

[0049] (1) take each raw material by the weight of above-mentioned novel high-strength furniture plate;

[0050] (2) mix each raw material, then add 200kg of water, mix well, obtain paste mixture;

[0051] (3) Pour the mixture into the mold, and then heat and extrude through the mold equipment to make a new type of high-strength furniture board.

Embodiment 2

[0053] New high-strength furniture boards, including the following raw materials: 120kg of wood fiber, 150kg of ordinary portland cement, 75kg of PVC resin powder, 70kg of light calcium carbonate, 8kg of paraffin wax, 8kg of amino resin glue, 2kg of nano-silver oxide, and antioxidant 10762kg, PE wax 1.5kg and stearic acid 1.5kg;

[0054] The preparation method of the above-mentioned novel high-strength furniture board specifically comprises the following steps:

[0055] (1) take each raw material by the weight of above-mentioned novel high-strength furniture plate;

[0056] (2) mix each raw material, then add 250kg of water, mix well, obtain paste mixture;

[0057] (3) Pour the mixture into the mold, and then heat and extrude through the mold equipment to make a new type of high-strength furniture board.

Embodiment 3

[0059] New high-strength furniture boards, including the following raw materials: 150kg of wood fiber, 200kg of ordinary Portland cement, 80kg of PVC resin powder, 80kg of light calcium carbonate, 10kg of asphalt, 10kg of hot-melt adhesive, 3kg of nano-copper oxide, anti-oxidant Agent 1643kg, PE wax 1kg and stearic acid 1kg;

[0060] The preparation method of the above-mentioned novel high-strength furniture board specifically comprises the following steps:

[0061] (1) take each raw material by the weight of above-mentioned novel high-strength furniture plate;

[0062] (2) Mix each raw material, then add 300kg of water, mix well, and obtain paste mixture;

[0063] (3) Pour the mixture into the mold, and then heat and extrude through the mold equipment to make a new type of high-strength furniture board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com