Preparation method of stably dispersed nano 8YSZ aqueous phase suspension

A water-phase suspension and dispersion stabilization technology, applied in coatings and other directions, can solve problems such as unsustainable dispersion effect, reduced performance of nanomaterials, thermodynamic instability of two-phase dispersion system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

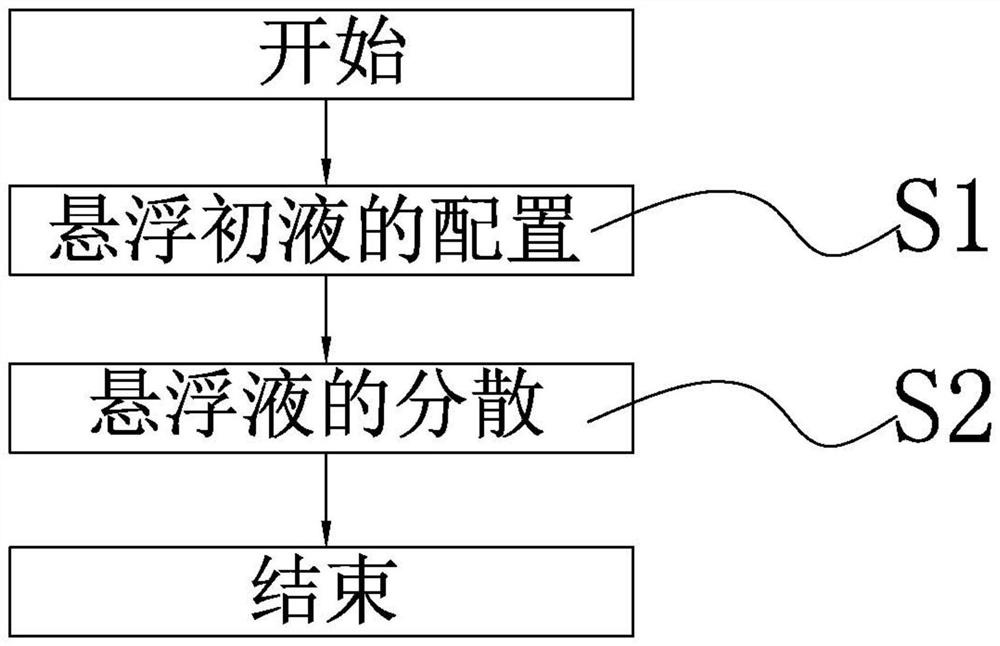

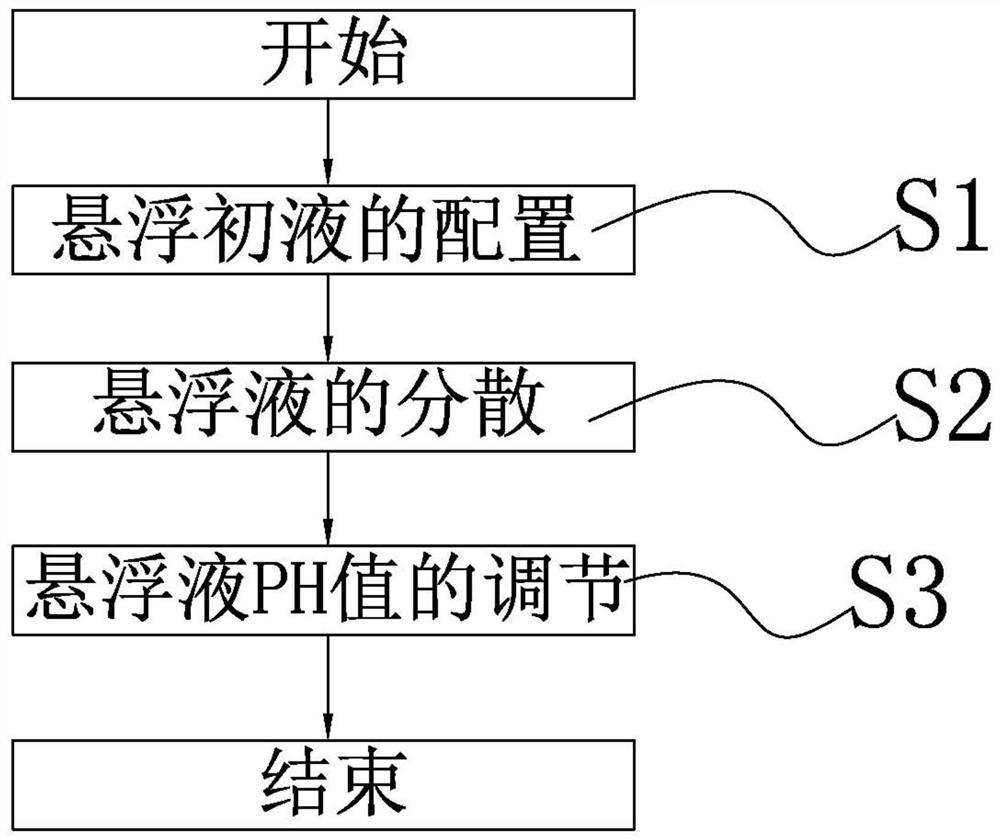

[0042] refer to figure 1 , figure 1 It is the flow process of the preparation method of a kind of dispersion stable nanometer 8YSZ aqueous phase suspension of the present invention Figure 1 .

[0043] This implementation provides a kind of preparation method of dispersed stable nano 8YSZ aqueous phase suspension, comprising the following steps:

[0044] S1. Configuration of initial suspension liquid: Weigh nanometer 8YSZ powder, add deionized water, stir evenly, and obtain initial suspension liquid with a solid phase mass fraction of 20%;

[0045] S2. Dispersion of the suspension: adding a dispersant to the initial suspension liquid for dispersion treatment to obtain a suspension.

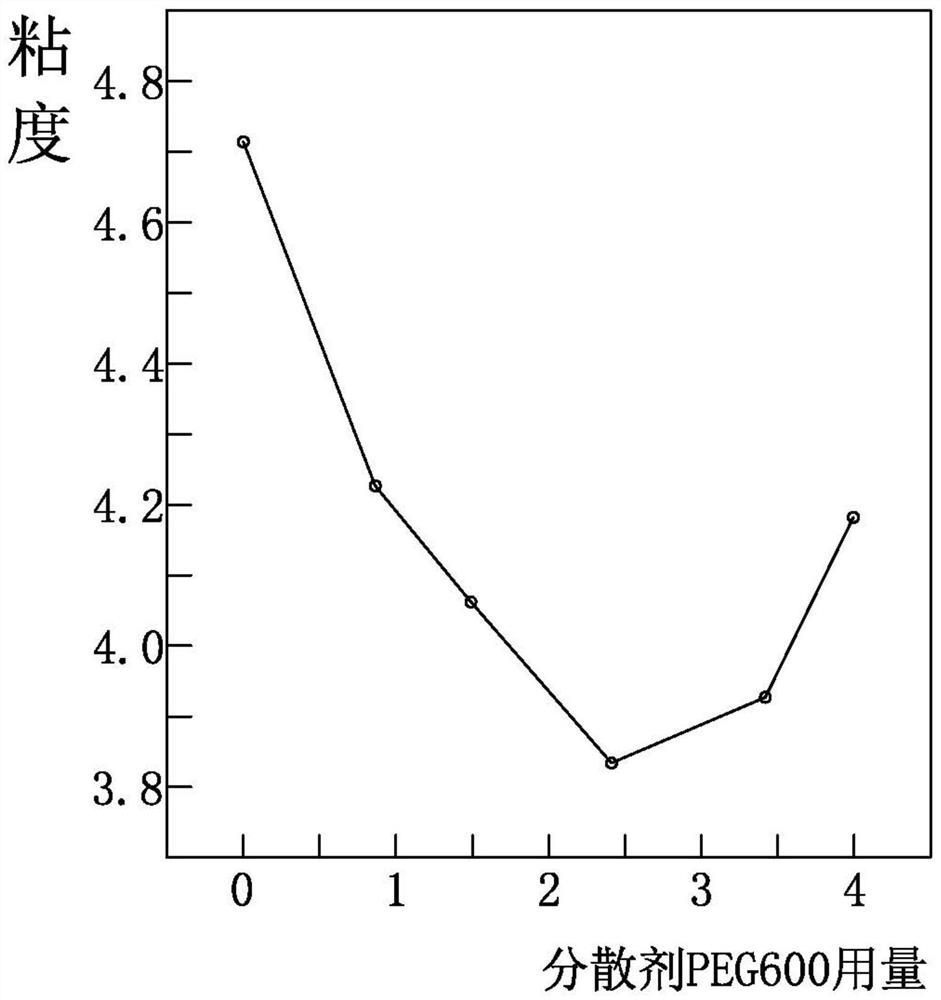

[0046] This dispersing agent is the polyethylene glycol reagent (being called for short PEG) that mass fraction is 0~4%, and this polyethylene glycol reagent is the polyethylene glycol reagent (being called for short PEG600) that molecular weight is 600, and its grade is chemically pure, by Pr...

Embodiment 2

[0053] refer to figure 1 , figure 1 It is the flow process of the preparation method of a kind of dispersion stable nanometer 8YSZ aqueous phase suspension of the present invention Figure 1 .

[0054] This implementation provides a kind of preparation method of dispersed stable nano 8YSZ aqueous phase suspension, comprising the following steps:

[0055] S1. Configuration of initial suspension liquid: Weigh nanometer 8YSZ powder, add deionized water, stir evenly, and obtain initial suspension liquid with a solid phase mass fraction of 20%;

[0056] S2. Dispersion of the suspension: adding a dispersant to the initial suspension liquid for dispersion treatment to obtain a suspension.

[0057] This dispersion agent is the polyethylene glycol reagent (being called for short PEG) that mass fraction is 0~4%, and this polyethylene glycol reagent is the polyethylene glycol reagent (being called for short PEG2000) that molecular weight is 2000, and its grade is chemically pure, by ...

Embodiment 3

[0064] refer to figure 1 , figure 1 It is the flow process of the preparation method of a kind of dispersion stable nanometer 8YSZ aqueous phase suspension of the present invention Figure 1 .

[0065] This implementation provides a kind of preparation method of dispersed stable nano 8YSZ aqueous phase suspension, comprising the following steps:

[0066] S1. Configuration of initial suspension liquid: Weigh nanometer 8YSZ powder, add deionized water, stir evenly, and obtain initial suspension liquid with a solid phase mass fraction of 20%;

[0067] S2. Dispersion of the suspension: adding a dispersant to the initial suspension liquid for dispersion treatment to obtain a suspension.

[0068] The dispersant is a polypropylene agent (abbreviated as PAA) with a mass fraction of 0-4%, its grade is chemically pure, and it is provided by Shandong Taihe Water Treatment Co., Ltd.

[0069] The nano 8YSZ powder has a particle size of 40nm and a specific surface area of 25m 2 / g, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com