Red chocolate, red chocolate coating and frozen drink

A technology for chocolate coating and frozen drinks, which is applied in food freezing, frozen desserts, food ingredients, etc. It can solve the problems of easy cracking, low gloss of red chocolate coating, and rough surface, so as to improve the smoothness and improve the overall quality. Likeability, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

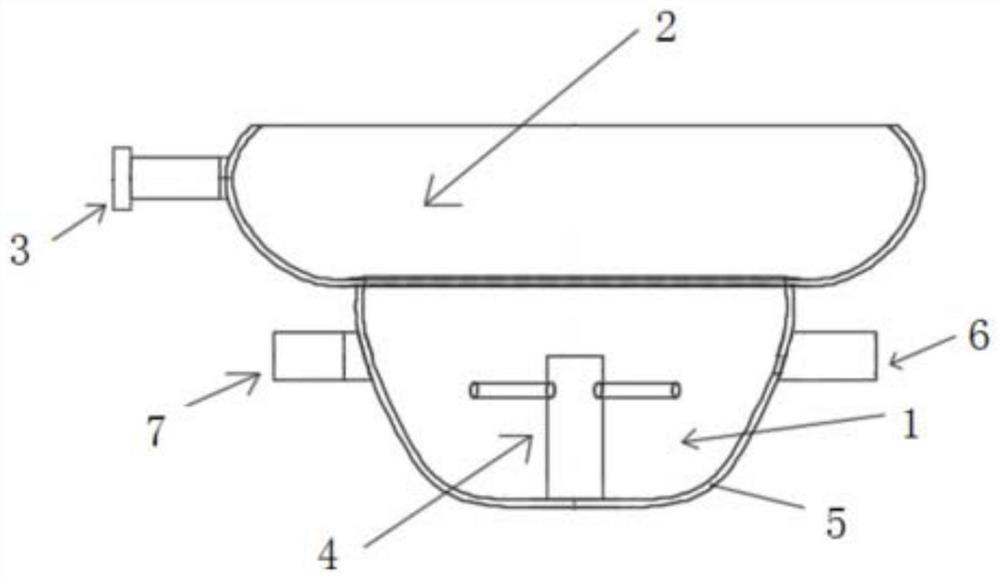

Image

Examples

Embodiment 1

[0071] (1) present embodiment also provides a kind of red chocolate, and its formula and preparation method are as follows:

[0072] Formula: 30kg of cocoa butter, 25.184kg of white sugar, 17kg of whole milk powder, 27kg of refined coconut oil, 0.8kg of phospholipids, 0.016kg of pigment composition for chocolate; wherein, 0.005kg of cochineal red, 0.005kg of carmine Mossine 0.008kg, allura red 0.003kg.

[0073] Preparation method: weigh each raw material according to the formula, mix, grind, finely grind, cool, and set aside.

[0074] The specific method is as follows: weigh each raw material according to the formula, grind the white granulated sugar, and then mix it evenly with the pigment composition for chocolate and whole milk powder to make a mixture material 1; heat up the cocoa butter and refined coconut oil to 70°C Insulate for 5 hours (all melted), then add phospholipids and mix evenly, then cool down to 37°C to make mixture 2; mix mixture 1 and mixture 2 and put the...

Embodiment 2

[0097] (1) The present embodiment also provides a kind of red chocolate, and its raw material comprises the following components: 25kg of cocoa butter, 30.486kg of white granulated sugar, 15kg of skimmed milk powder, 29kg of refined soybean oil, 0.5kg of lecithin, pigment composition for chocolate: 0.014 kg; Wherein, the pigment composition for chocolate comprises: cochineal 0.006kg, erythrosine 0.007kg, allura red 0.001kg.

[0098] This embodiment also provides a production process of red chocolate, which includes the following steps: weighing each raw material according to the formula, grinding white sugar, and then mixing it with the pigment composition for chocolate and skimmed milk powder to make a mixing material 1. Heat cocoa butter and refined soybean oil to 70°C and keep warm for 5 hours (all melted), then add phospholipids and mix evenly, then cool down to 37°C to make mixture 2; mix mixture 1 and mixture 2 and put them into grinding Grind in the machine for 50 minut...

Embodiment 3

[0116] (1) The present embodiment also provides a kind of red chocolate, and its raw material comprises following components: 35kg of cocoa butter, 20.185kg of white granulated sugar, 19kg of whole milk powder, 25kg of refined coconut oil, 0.8kg of lecithin, the pigment composition for chocolate: 0.015kg. The pigment composition for chocolate comprises: 0.004 kg of cochineal, 0.006 kg of erythrosine, and 0.005 kg of allura red.

[0117] This embodiment also provides a manufacturing process of red chocolate, which is the same as that in Embodiment 1.

[0118] (2) present embodiment also provides a kind of red mixed chocolate, and its raw material comprises following components: red chocolate 70kg of present embodiment, white pure fat chocolate 22kg, milk flavor pure fat chocolate 8kg; Evenly.

[0119] Among them, the formula and production process of white pure fat chocolate are as follows:

[0120] Formula: including white sugar 22kg, edible glucose powder 6.7kg, polydextro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com