Milk-flavored pure-fat chocolate, frozen beverage and preparation method

A frozen drink and chocolate technology, which is applied in frozen desserts, cocoa, food science, etc., can solve the problems of sweet milk-flavored pure fat chocolate, bubbles on the surface of the product, and lack of milky flavor, etc., to achieve prominent frankincense flavor and smooth surface , strong frankincense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

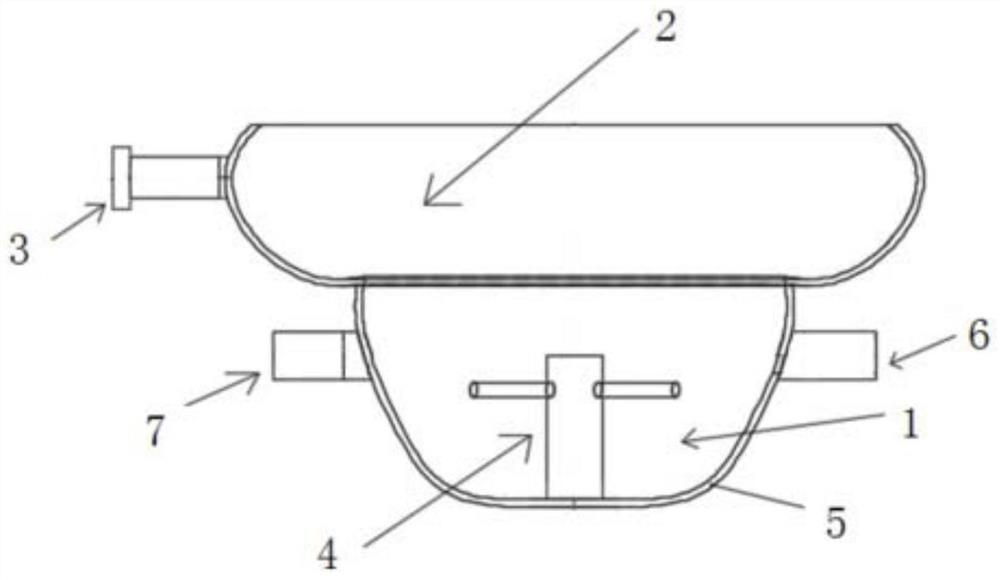

Image

Examples

Embodiment 1

[0049] This embodiment provides a frozen drink, including a core material and a milk-flavored pure fat chocolate coating coated on the surface of the core material, wherein,

[0050] (1) The formula of milk-flavored pure fat chocolate is: white sugar 20kg; skimmed milk powder 20kg; anhydrous butter 25kg; cocoa butter 30kg; crystalline fructose 1.6kg; lactose 2.5kg; vanillin 0.1kg;

[0051] (2) The production process of milk-flavored pure fat chocolate is: raw material processing - mixing - grinding - fine grinding - cooling - degassing.

[0052] 1) Raw material processing: grind white sugar, crystallized fructose, and lactose into powder, then mix milk powder, vanillin and white sugar evenly to make mixed material 1;

[0053] 2) Heat cocoa butter and anhydrous butter to 70°C and keep it warm for 5 hours (all melted), then add emulsifier and mix evenly, then cool down to 45°C to make mixture 2;

[0054] 3) Mix the mixed material 1 and the mixed material 2 and put them into a g...

Embodiment 2

[0072] This embodiment provides a frozen drink, including a core material and a milk-flavored pure fat chocolate coating coated on the surface of the core material, wherein,

[0073] (1) The formula of milk-flavored pure fat chocolate is: white granulated sugar 25kg; skimmed milk powder 15kg; anhydrous butter 20kg; cocoa butter 35kg; crystalline fructose 1.05kg; lactose 3.5kg; vanillin 0.05kg;

[0074] (2) The production process of milk-flavored pure fat chocolate is: raw material processing - mixing - grinding - fine grinding - cooling - degassing.

[0075] 1) Raw material processing: grind white sugar, crystallized fructose, and lactose into powder, then mix milk powder, vanillin and white sugar evenly to make mixed material 1;

[0076] 2) Heat cocoa butter and anhydrous butter to 65°C and keep warm for 6 hours (all melted), then add emulsifier and mix evenly, then cool down to 40°C to make mixture 2;

[0077] 3) Mix the mixed material 1 and the mixed material 2 and put the...

Embodiment 3

[0095] This embodiment provides a frozen drink, including a core material and a milk-flavored pure fat chocolate coating coated on the surface of the core material, wherein,

[0096](1) The formula of milk-flavored pure fat chocolate is: white sugar 15.15kg; skimmed milk powder 25kg; anhydrous butter 30kg; cocoa butter 25kg; crystalline fructose 2kg; lactose 1.5kg; vanillin 0.15kg; phospholipid 1.2kg.

[0097] (2) The production process of milk-flavored pure fat chocolate is: raw material processing - mixing - grinding - fine grinding - cooling - degassing.

[0098] 1) Raw material processing: grind white sugar, crystallized fructose, and lactose into powder, then mix milk powder, vanillin and white sugar evenly to make mixed material 1;

[0099] 2) Heat cocoa butter and anhydrous butter to 75°C and keep it warm for 4 hours (all melted), then add emulsifier and mix evenly, then cool down to 50°C to make mixture 2;

[0100] 3) Mix the mixed material 1 and the mixed material 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com