Application of metallurgical surfactant

A surfactant and metallurgical technology, applied in the application field of metallurgical surfactants, can solve the problems of poor flotation effect of celestite ore, poor grade and recovery rate of celestite concentrate, etc., and achieve good promotion and application value, Increased hydrophobic capacity and strong collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

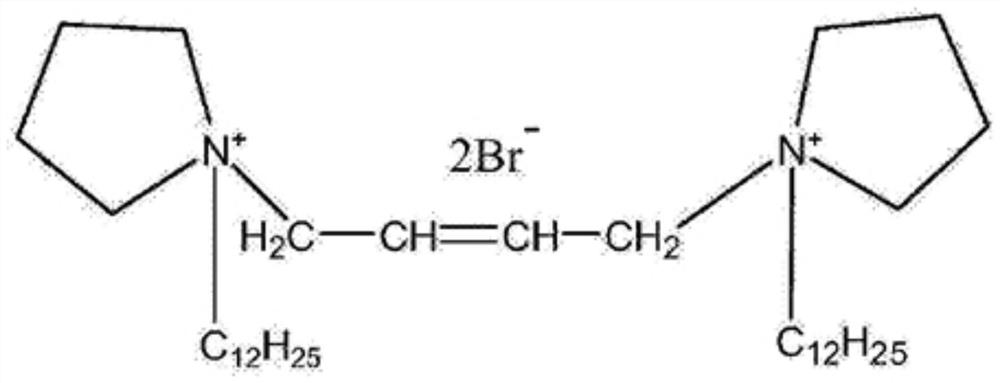

[0026] Such as figure 1 Shown, the embodiment of the present invention provides a kind of application of metallurgical surfactant, will have figure 1 Structured metallurgical surfactant 2-butene-1,4-bis(dodecylpyrrolidinyl ammonium bromide) is used as collector in lapis lazuli ore flotation, water glass is inhibitor, terpineol oil As a foaming agent, when the lapis lazuli ore contains 35% strontium sulfate, and the particle size is -200 mesh accounting for 90%, add water to adjust the slurry to a mass concentration of 40%, and adopt a flotation process of one roughing, one sweeping, and three selections The process, the flotation temperature is 20-30°C, and the reagent system is: adding 500g / t 2-butene-1,4-bis(dodecylpyrrolidinyl ammonium bromide) and 150g / t terpineol oil for roughing , add 200g / t 2-butene-1,4-bis(dodecylpyrrolidinyl ammonium bromide) to the sweeping, add 1200g / t water glass to the first selection, add 800g / t to the second selection t water glass, select and...

Embodiment 2

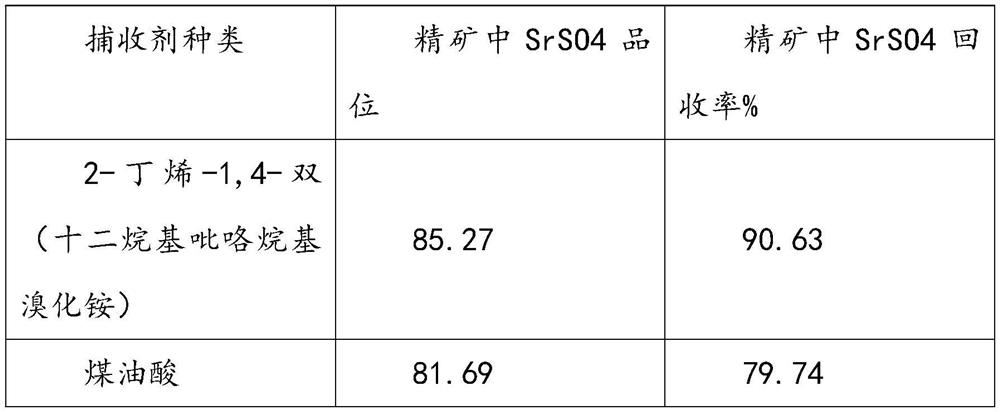

[0030] The difference between this example and Example 1 is that when the day’s lapis lazuli ore contains 50% strontium sulfate, and the particle size is -200 mesh accounting for 95%, add water to adjust the slurry to a mass concentration of 35%, and use one roughing and one sweeping , Twice selected flotation process, flotation temperature is 5-15 ℃, reagent system is: add 800g / t2-butene-1,4-bis(dodecylpyrrolidinyl ammonium bromide ), 150g / t pine alcohol oil, adding 300g / t2-butene-1,4-bis(dodecylpyrrolidinyl ammonium bromide) for sweeping, adding 1000g / t water glass for the first selection, and adding 1000g / t water glass for the first selection Secondary selection adds 500g / t water glass; A kind of metallurgical surfactant 2-butene-1,4-bis(dodecylpyrrolidinyl ammonium bromide) in the present invention and collector agent commonly used The results of the flotation comparison experiment are shown in the table below:

[0031]

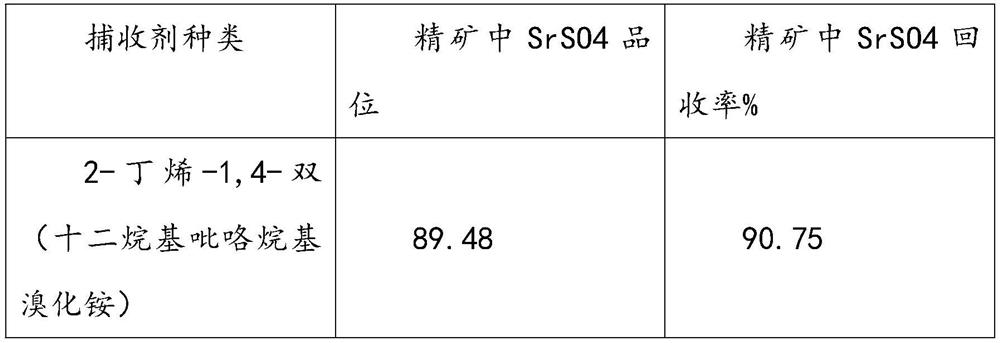

[0032]

[0033] A metallurgical surfactant o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com