A Harmless Slag Treatment System

A technology for processing systems and dregs, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as secondary pollution, environmental pollution, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

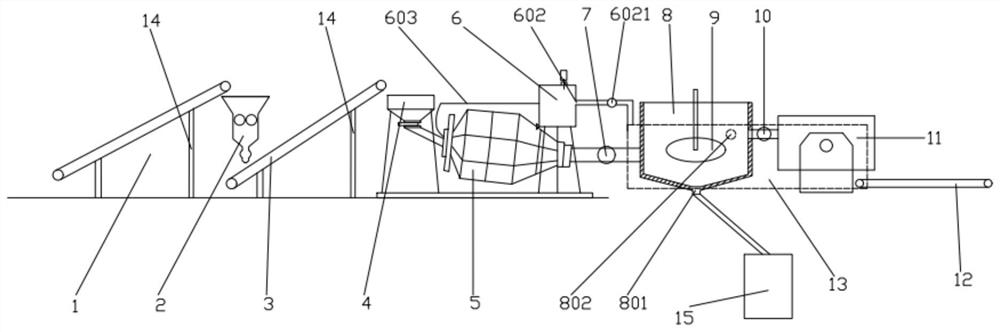

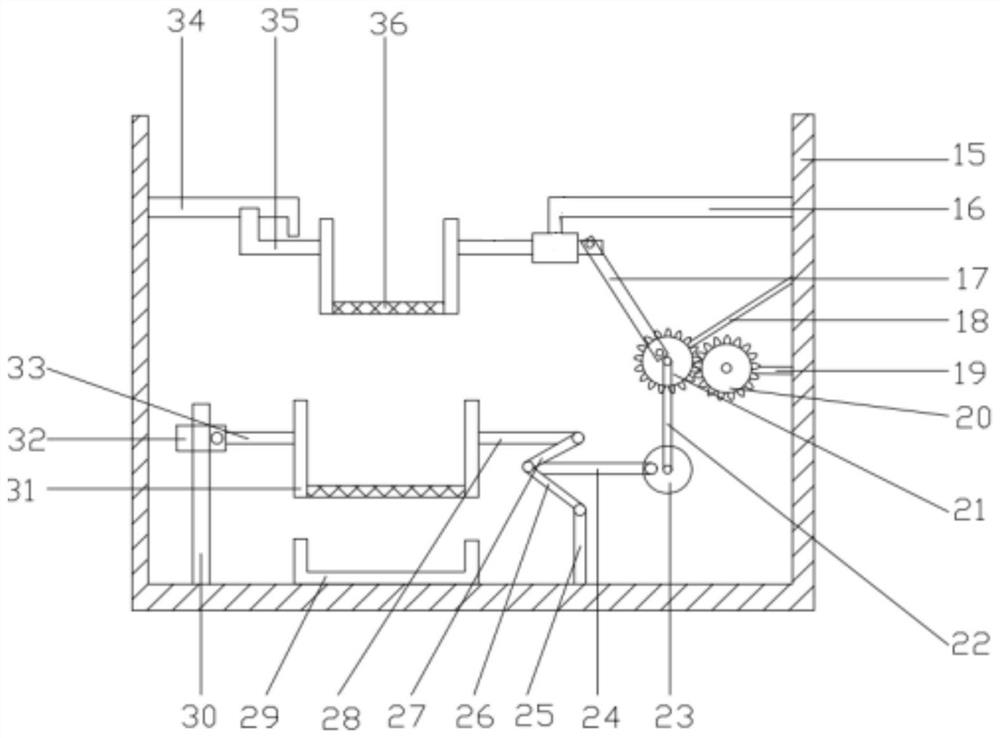

[0061] Embodiments of the present invention provide a harmless slag treatment system, such as figure 1 As shown, it includes a crusher 2, a stirring device 5, a repair box 6, a separation tank 8 and a filter press 11, the inlet of the crusher 2 is connected to the raw material conveying device 1, and the outlet of the crusher 2 is connected to the The first conveying device 3 is connected, and the first conveying device 3 is connected with the hopper 4;

[0062] The feed inlet of described stirring device 5 is connected with described hopper 4, and described stirring device 5 can be a rotary tank mixer, and the feed inlet of described stirring device 5 is also connected with repair box 6, and the outlet of described stirring device 5 The feed port is connected with the feed port of the separation tank 8;

[0063] The feed port of the filter press 11 is connected to the discharge port of the separation tank 8 through the filter press pump 10 , and the discharge port of the fil...

Embodiment 2

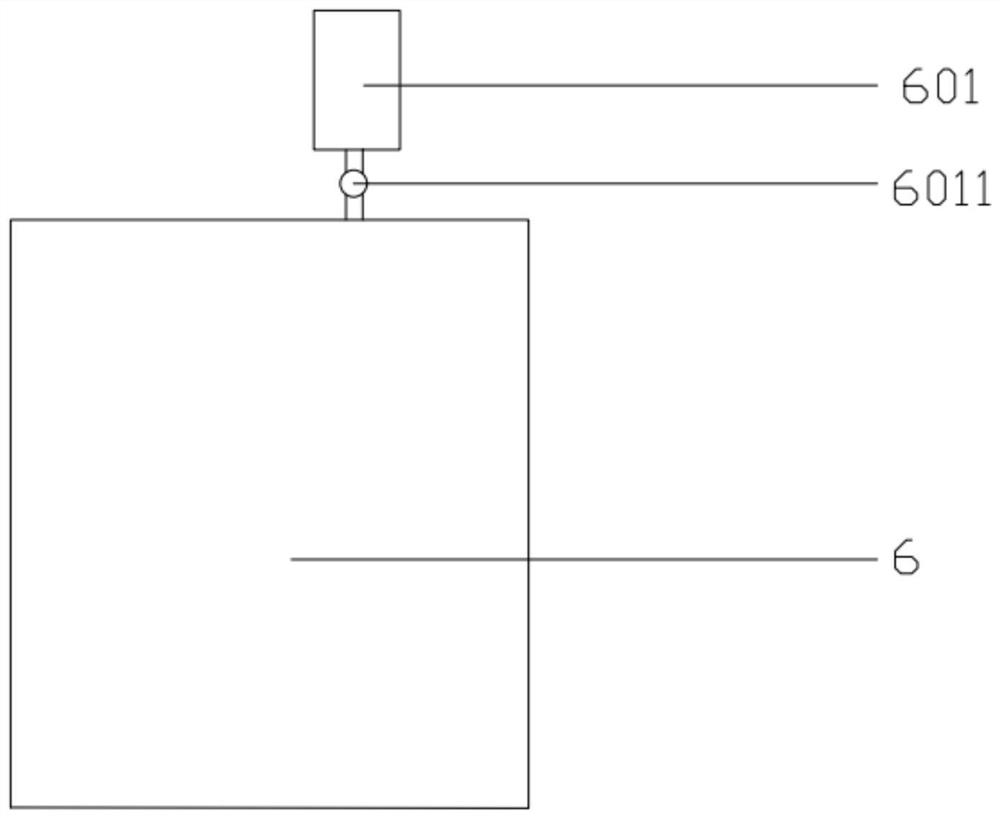

[0070] On the basis of above-mentioned embodiment 1, as Figure 1-Figure 2 As shown, the upper end of the repair box 6 is provided with a repair tank 601, and the repair tank 601 is provided with a repair liquid, a repair liquid (a mixture of reducing materials, release accelerators and water of slag raw materials), and the repair tank 6 A water outlet pipe 603 is provided at the left side, a water inlet 1 602 is provided at the right side of the repair box 6 , and a pump 7 is provided at the connecting part between the discharge port of the stirring device 5 and the feed port of the separation tank 8 .

[0071] The beneficial effect of above-mentioned technical scheme is:

[0072]The restoration tank 601 is set to facilitate the storage of the restoration liquid. The reduction material in the restoration liquid corresponds to the composition of the dregs raw material. For example, iron-sulfur-based reconstituted materials can be used as the reduction material for chromium-con...

Embodiment 3

[0074] On the basis of embodiment 1 or 2, such as figure 1 As shown, the bottom of the separation pool 8 is provided with an opening 801, the inside of the separation pool 8 is provided with a mixer 2 9, the mixer 9 can be a turbine mixer, and the rear end of the separation pool 8 is provided with a water inlet Two 802.

[0075] Described crusher 2, agitator 5, agitator 2 9 and filter press 11 all can select existing equipment for use.

[0076] The beneficial effect of above-mentioned technical scheme is:

[0077] By arranging the mixer 29, the separation of the sand and the mud can be made more obvious, preventing the mud from sinking to the bottom, and improving the recycling rate of the slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com