Polycarboxylate superplasticizer with polyphosphonate side chain and preparation method of polycarboxylate superplasticizer

A polyphosphonate and polycarboxylic acid technology, which is applied in the field of building materials, can solve the problems of aggravated loss of plasticizing properties of concrete mixtures, reduced utilization efficiency of water-reducing agents, troubles in on-site pouring, etc., so as to improve the steric hindrance effect. , the effect of reducing hydrophilicity and reducing the concentration of free water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

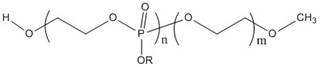

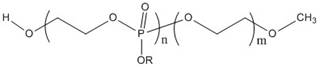

[0038] A preparation method of a polycarboxylate water reducer with a polyphosphonate side chain, used to prepare the polycarboxylate water reducer with a polyphosphonate side chain as claimed in any one of claims 1 to 2, wherein It is characterized in that: comprising the following steps:

[0039] Step 1: Put 2-chloro-2-oxo-1,3,2-dioxaphospholane, monohydric alcohol, solvent A1, and catalyst B1 in the reactor, replace the gas in the reactor with N2, and turn on Stir, react at room temperature for 4 to 7 hours, distill off the solvent, and the product obtained is a reaction intermediate P; the structural formula of the reaction intermediate P is as in formula (II):

[0040]

[0041] (II)

[0042] (II) In the formula, R is the alkyl part of a monohydric alcohol, that is, one of methyl, ethyl, propyl, isopropanol, n-butyl, and isobutyl.

[0043] Step 2: Place the reaction intermediate P, polyethylene glycol monomethyl ether, solvent A2, and catalyst B2 generated in step 1 i...

specific Embodiment 1

[0054] 142.5 parts by mass of 2-chloro-2-oxo-1,3,2-dioxaphospholane, 32 parts by mass of methanol, 3 parts by mass of triethanolamine, mass fraction 500 parts of tetrahydrofuran are placed in the reactor, and N 2 The gas in the reactor was replaced, the stirring device was turned on, and the reaction was carried out at room temperature for 7 hours. After the reaction was completed, it was purified by distillation to obtain 138 parts by mass of the reaction intermediate P1. Then in the reactor equipped with P1, add mass parts as 500 parts of dichloromethane, 50 parts by mass of polyethylene glycol monomethyl ether with a number average molecular weight of 500 and 2.5 parts by mass of isooctanoic acid Sn, using N 2 The gas in the reactor was replaced, the stirring device was turned on, the temperature was controlled at 0-20°C, the ring-opening polymerization was carried out for 1 hour, and the linear macromolecule E1 of polyethylene glycol-polyphosphonate monomethyl ether was o...

specific Embodiment 2

[0058] 142.5 parts by mass of 2-chloro-2-oxo-1,3,2-dioxaphospholane, 60 parts by mass of isopropanol, 3.5 parts by mass of triethanolamine, Mass fraction is 500 parts of tetrahydrofuran placed in the reactor, using N 2 The gas in the reactor was replaced, the stirring device was turned on, and the reaction was carried out at room temperature for 6 hours. After the reaction, distillation and purification were performed to obtain 166 parts by mass of the reaction intermediate P2. Then in the reactor equipped with P2, add mass parts as 500 parts of dichloromethane, 125 parts by mass of polyethylene glycol monomethyl ether with a number average molecular weight of 500 and 4.5 parts by mass of 1, 8-diazabicyclo[5.4.0]undec-7-ene, using N 2 The gas in the reactor was replaced, the stirring device was turned on, the temperature was controlled at 0-20°C, the ring-opening polymerization was carried out for 1 hour, and the linear macromolecule E2 of polyethylene glycol-polyphosphonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com