Irradiation chlorosulfonated polyethylene material and preparation process thereof

A technology of chlorosulfonated polyethylene and chlorinated polyethylene, which is applied in the field of cable materials, can solve TOTM hazards and other problems, and achieve the effects of reducing pollution emissions, long storage period, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

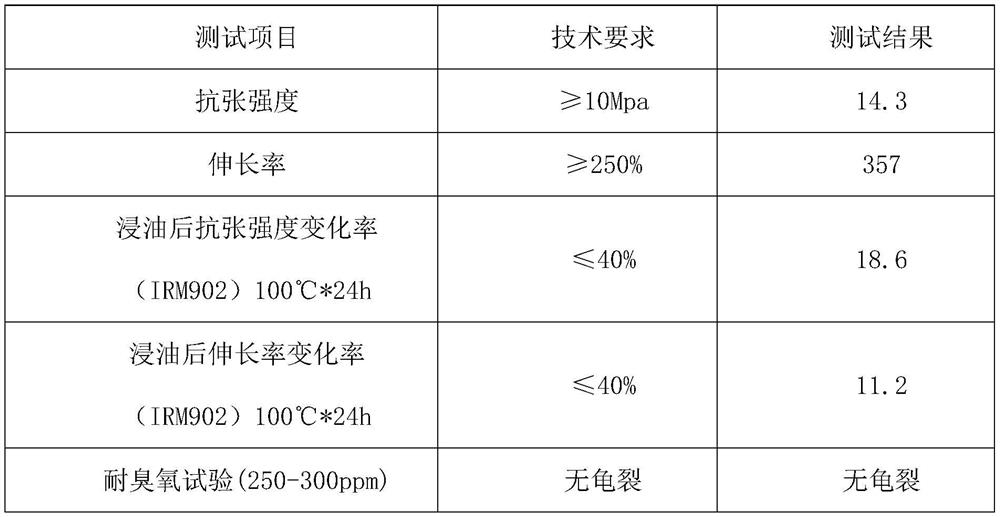

Embodiment 1

[0027] An irradiated chlorosulfonated polyethylene material, comprising the following raw materials in parts by weight: 40 parts of chlorosulfonated polyethylene, 60 parts of chlorinated polyethylene, 25 parts of N330 carbon black, 80 parts of kaolin, 10 parts of magnesium oxide, chlorine 8 parts of paraffin wax, 2 parts of radiation crosslinking agent and 2.6 parts of anti-aging agent.

[0028] Further, the chlorosulfonated polyethylene adopts polyethylene derivatives after chlorination and sulfonation treatment, the chlorine content is 35%, the sulfur content is 1.5%, and the chlorinated polyethylene is rubber type B chlorinated polyethylene, the chlorine The content is 35%.

[0029] Specifically, the chlorinated paraffin is an environment-friendly short-chain chlorinated paraffin, and the irradiation crosslinking agent is specifically trimethylolpropane trimethacrylate.

[0030] In addition, the anti-aging agent adopts the mixture of anti-aging agent RD, antioxidant 1010 a...

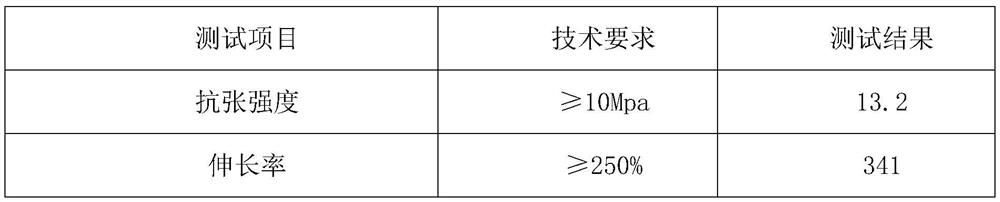

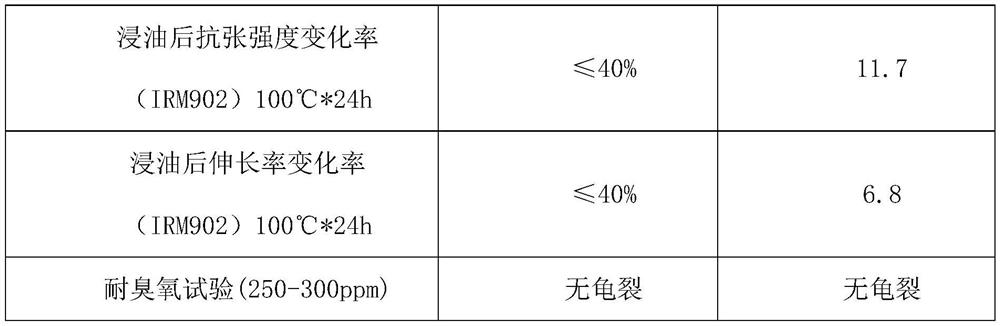

Embodiment 2

[0040] An irradiated chlorosulfonated polyethylene material, comprising the following raw materials in parts by weight: 50 parts of chlorosulfonated polyethylene, 50 parts of chlorinated polyethylene, 20 parts of N330 carbon, 70 parts of kaolin, 10 parts of magnesium oxide, chlorinated 8 parts of paraffin, 3 parts of radiation crosslinking agent and 3.5 parts of anti-aging agent.

[0041] Further, the chlorosulfonated polyethylene adopts polyethylene derivatives after chlorination and sulfonation treatment, the chlorine content is 35%, the sulfur content is 1.5%, and the chlorinated polyethylene is rubber type B chlorinated polyethylene, the chlorine The content is 35%.

[0042] Specifically, the chlorinated paraffin is an environment-friendly short-chain chlorinated paraffin, and the irradiation crosslinking agent is specifically trimethylolpropane trimethacrylate.

[0043] In addition, the anti-aging agent adopts the mixture of anti-aging agent RD, antioxidant 1010 and micr...

Embodiment 3

[0054] An irradiated chlorosulfonated polyethylene material, comprising the following raw materials in parts by weight: 45 parts of chlorosulfonated polyethylene, 55 parts of chlorinated polyethylene, 30 parts of N330 carbon black, 70 parts of kaolin, 12 parts of magnesium oxide, chlorine 10 parts of chemical paraffin, 2.5 parts of radiation crosslinking agent and 3.5 parts of anti-aging agent.

[0055] Further, the chlorosulfonated polyethylene adopts polyethylene derivatives after chlorination and sulfonation treatment, the chlorine content is 35%, the sulfur content is 1.5%, and the chlorinated polyethylene is rubber type B chlorinated polyethylene, the chlorine The content is 35%.

[0056] Specifically, the chlorinated paraffin is an environment-friendly short-chain chlorinated paraffin, and the irradiation crosslinking agent is specifically trimethylolpropane trimethacrylate.

[0057] In addition, the anti-aging agent adopts the mixture of anti-aging agent RD, antioxidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com