Modified PGA material compatibilized by adopting intercalation structure and preparation method thereof

A layer structure and modification technology, which is applied in the field of modified PGA materials with intercalation structure and its preparation, can solve the problems of short repeating units, high melting point and high hardness of PGA materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The raw materials for the preparation of the modified PGA material provided by the present invention include 3 to 5 parts of plasticizer; the plasticizer is a mixture of polyvinyl alcohol and ethylene glycol, the molecular weight of polyvinyl alcohol is 500 to 800 g / mol, and the degree of alcoholysis is 88 %~95%. The mass ratio of polyvinyl alcohol and ethylene glycol is preferably 1:0.9-1.1, more preferably 1:1. Polyvinyl alcohol needs to control the molecular weight and degree of alcoholysis. The low molecular weight cannot achieve the plasticizing effect, and the friction between the PGA segments is relatively large. Polyvinyl alcohol with too large molecular weight will affect the phase size of PGA blends, which is also unfavorable to processing. The alcoholysis degree of 88% is mainly to improve the compatibility between the plasticizer itself and the PGA material. In a specific embodiment, the degree of alcoholysis of the polyvinyl alcohol used is 88%, and the m...

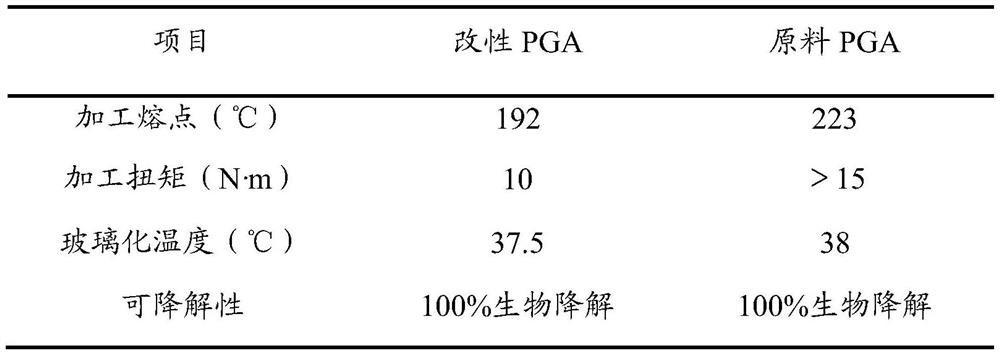

Embodiment 1

[0045] According to the weight ratio of raw materials: 5 parts of plasticizer, 80 parts of polyglycolic acid (PGA) with a molecular weight of 300,000, and 30 parts of organic nano-montmorillonite;

[0046]The plasticizer is obtained by mixing polyvinyl alcohol with a molecular weight of 800 and industrial grade ethylene glycol with an alcoholysis degree of 88%, and drying at 65°C for 6 hours, and mixing with a high-speed mixer for 30 minutes. blended materials;

[0047] The above-mentioned materials are extruded by twin-screw, and the raw materials are first mixed with a high-speed mixer for 15 minutes, and the obtained mixture is dried for 14 hours at a relative humidity of 25% and a temperature of 25-30°C, and the weight loss moisture content is between 1.5-2%. Then put it into the twin-screw extruder for granulation; the length-to-diameter ratio of the twin-screw extruder must be at least 1:55, while the temperature of the feeding section is kept at about 170°C, the tempera...

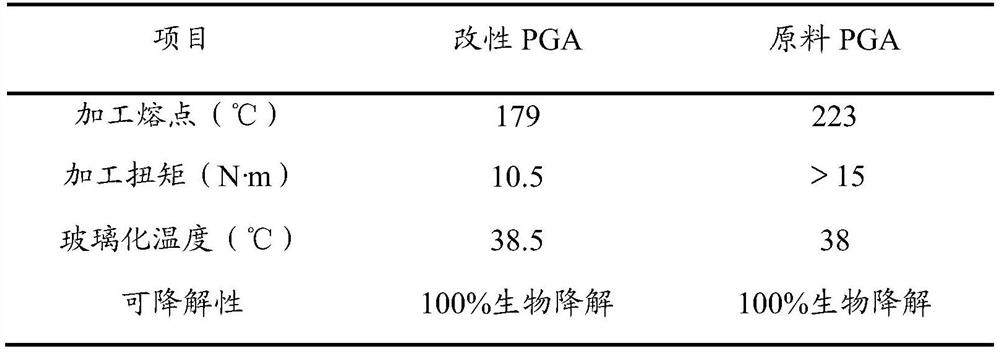

Embodiment 2

[0052] According to the weight ratio of raw materials: 3 parts of plasticizer, 75 parts of polyglycolic acid (PGA) with a molecular weight of 500,000, 20 parts of organic nano-montmorillonite;

[0053] The plasticizer is obtained by mixing polyvinyl alcohol with a molecular weight of 800 and industrial grade ethylene glycol with an alcoholysis degree of 95%, and drying at 65°C for 6 hours, and mixing with a high-speed mixer for 30 minutes. blended materials;

[0054] The above-mentioned materials are extruded by twin-screw, and the raw materials are first mixed with a high-speed mixer for 15 minutes, and the obtained mixture is dried for 14 hours at a relative humidity of 25% and a temperature of 25-30°C, and the weight loss moisture content is between 1.5-2%. Then put it into the twin-screw extruder for granulation; the aspect ratio of the twin-screw extruder must be at least 1:55, while the temperature of the feeding section is kept at about 170°C, the temperature of the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com