Inorganic modified single-component water-based surface cleaning material and preparation method thereof

An inorganic modification, one-component technology, applied in the direction of coating, etc., can solve the problems of reducing VOC emissions, the inlet pipe is not as good as oily single-component surface coatings, etc., and achieve the effect of improving weather resistance and improving wetting and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

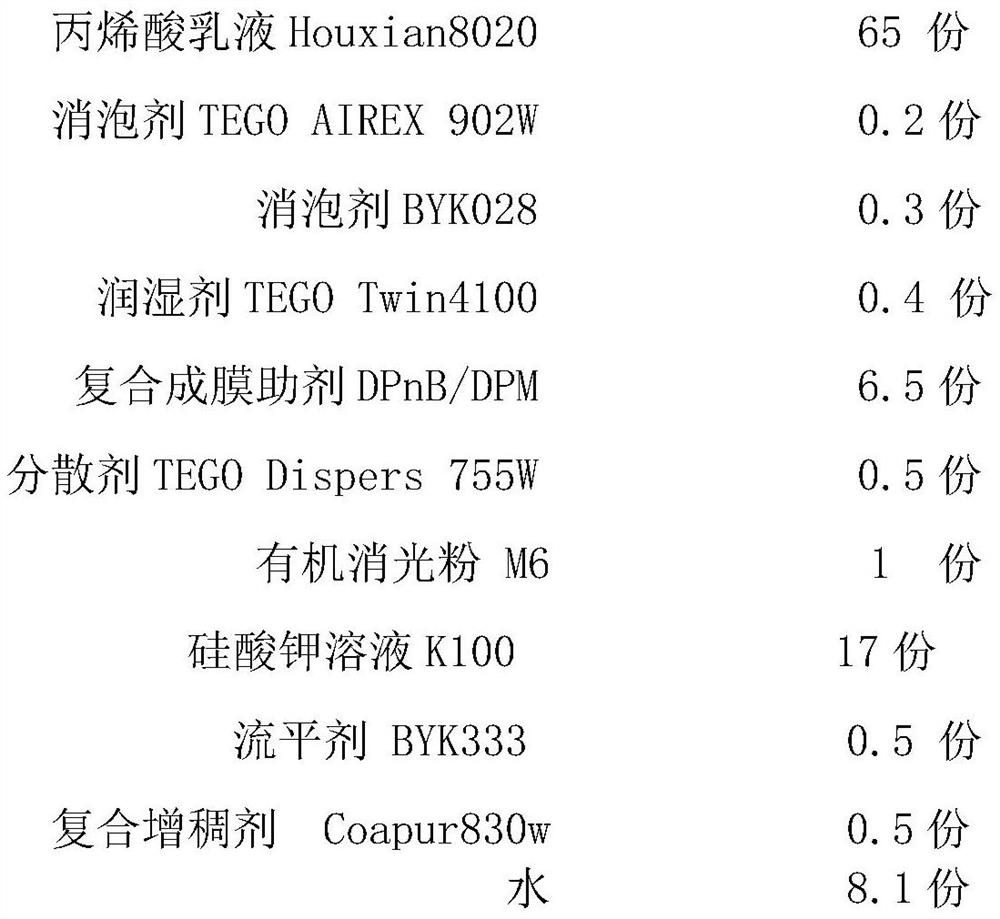

[0030] An inorganic modified single-component water-based surface cleaning material, comprising by weight:

[0031]

[0032] Preparation:

[0033] Mix polyacrylic acid emulsion, defoamer, wetting agent, and composite film-forming aids evenly by weight, disperse at high speed for 5 minutes until no oil shrinkage, then add dispersant at low speed, then add organic matting powder, and disperse at high speed When the fineness is less than or equal to 20 microns, add inorganic silicate solution and leveling agent to disperse evenly, then slowly add the remaining compound thickener and water to adjust to the national standard viscosity, and pack it for inspection.

Embodiment 2

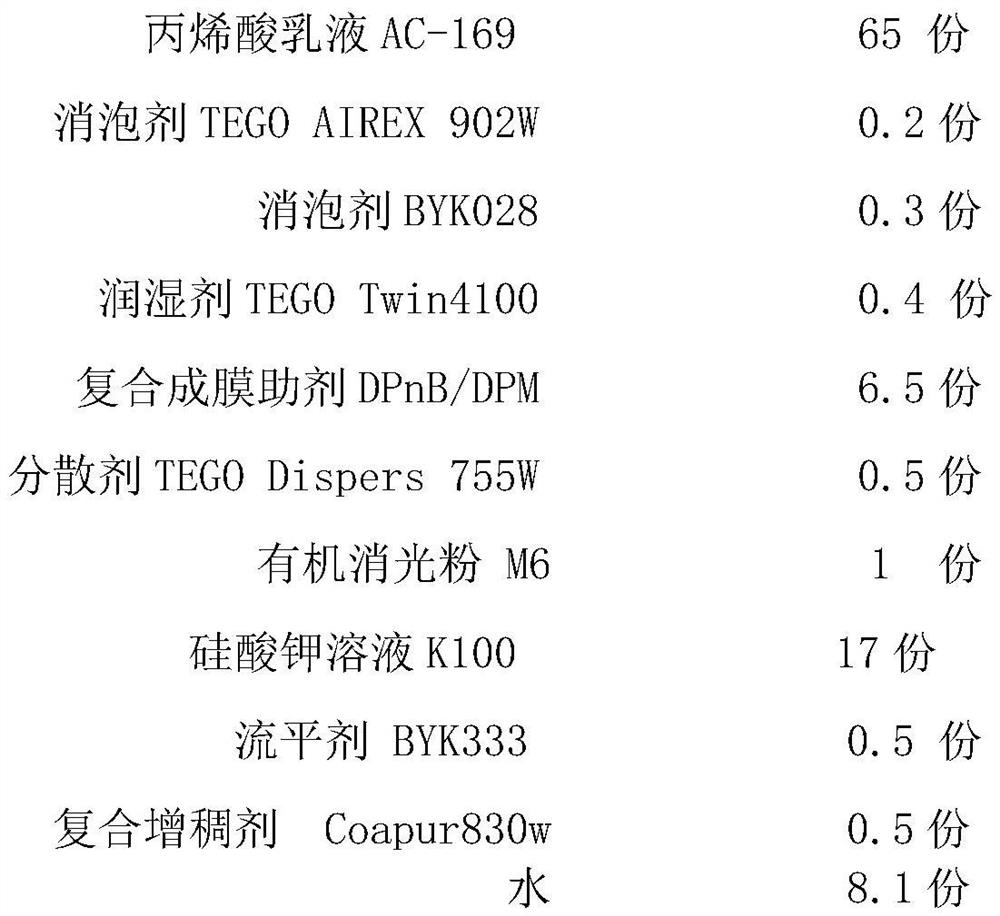

[0035] An inorganic modified single-component water-based surface cleaning material, comprising by weight:

[0036]

[0037] The preparation process is the same as that of Example 1, except that the acrylic emulsion of this example uses AC-169.

Embodiment 3

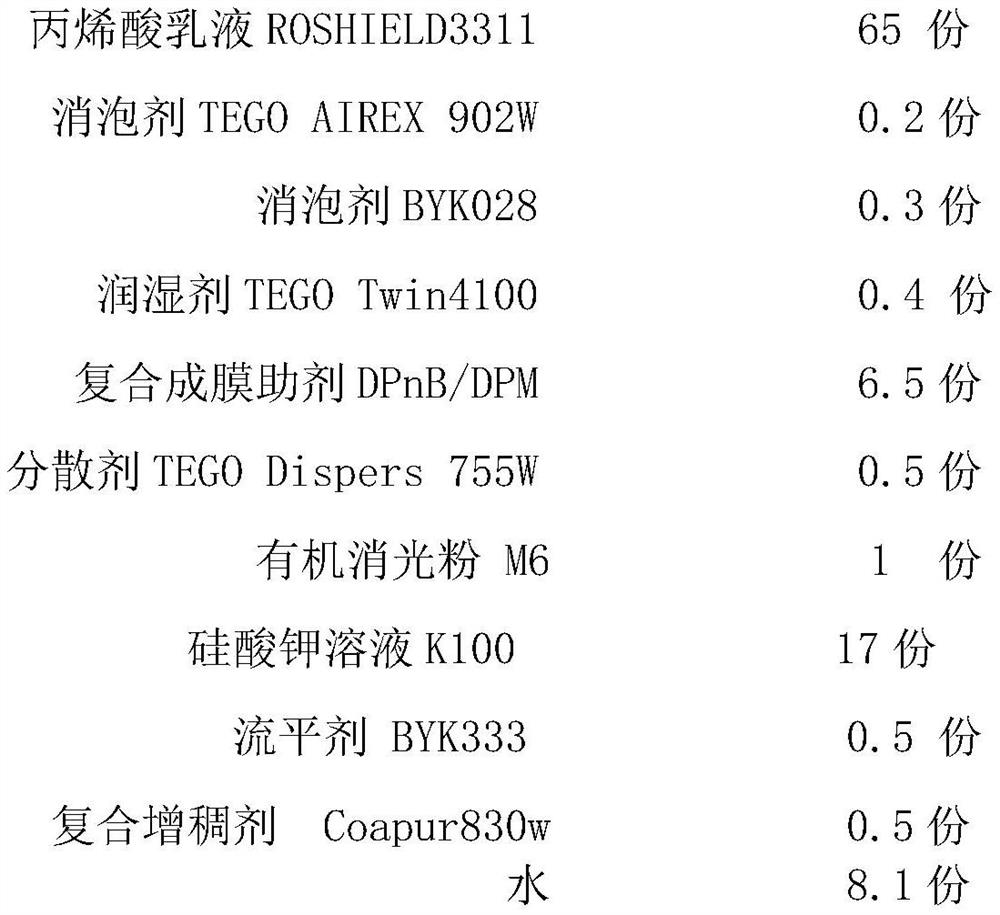

[0039] An inorganic modified single-component water-based surface cleaning material, comprising by weight:

[0040]

[0041] The preparation process is the same as that of Example 1, except that the acrylic emulsion of this example uses ROSHIELD3311.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com