A kind of iron-chromium-aluminum alloy manufacturing process

An iron-chromium-aluminum alloy, manufacturing process technology, applied in metal processing equipment, grain processing, transportation and packaging, etc., can solve problems such as unsatisfactory quality and environmental protection, unstable processing quality, and problematic processing methods, and achieve improvement The overall quality is stable, the calcination is thorough, and the effect of heating and calcination is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

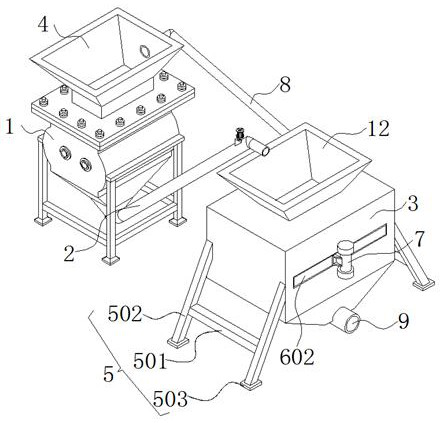

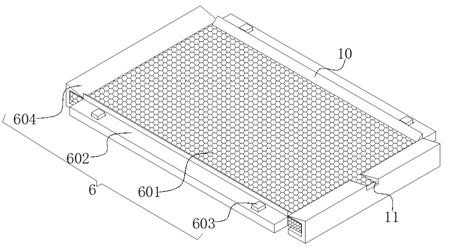

[0034] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified and described in detail below with the accompanying drawings.

[0035] The structure of the present invention will be described in detail below with reference to the accompanying drawings.

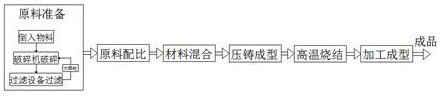

[0036] like Figure 1 to Figure 4 As shown, an iron-chromium-aluminum alloy manufacturing process provided by an embodiment of the present invention includes the following steps:

[0037] a. Preparation of raw materials: First, crush and filter the corresponding required materials through crushing and filtering equipment;

[0038] b. Raw material ratio: prepare raw materials according to a certain proportion;

[0039] c. Material mixing: Mix a variety of raw materials through a mixer;

[0040] d. Die-casting molding: put the mixed material into the die-casting mold, and die-casting the material through a die-casting machine;

[0041] e. High...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com