Vanadium diselenide doped nickel cobalt selenide yolk shell structure micron cuboid counter electrode catalyst and preparation method and application thereof

An electrode catalyst, vanadium diselenide technology, applied in circuits, capacitors, photovoltaic power generation, etc., can solve problems such as poor compromise, low reserves, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

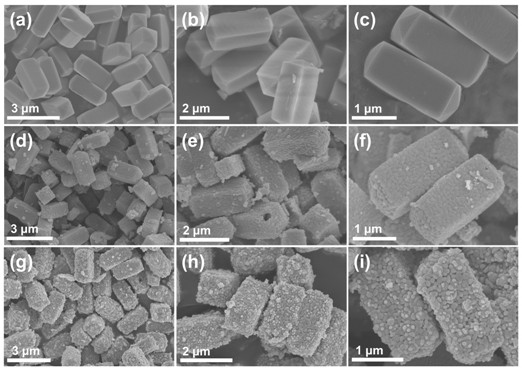

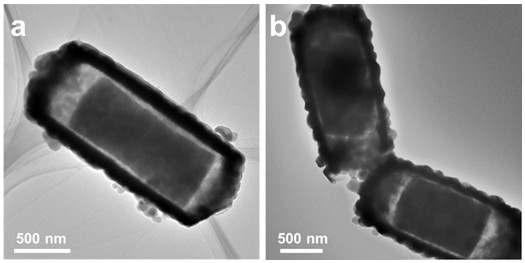

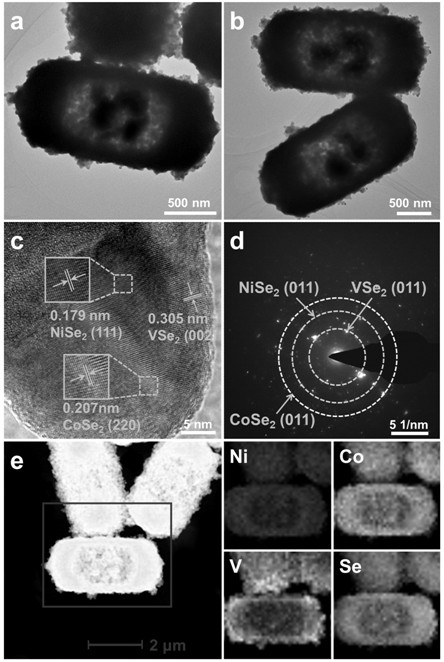

[0030] Dissolve 600 mg of cobalt acetate and 600 mg of nickel acetate in 70 mL of ethanol solution, and the resulting solution is solution A. Dissolve 2400 mg of polyvinylpyrrolidone in 120 mL of ethanol, and the resulting solution is solution B; slowly pour solution A into solution B, Stirring in a water bath at 80 °C for 1.5 h resulted in the precipitation of Ni-Co prism precursors. After centrifugal washing and drying, 140 mg of the obtained Ni-Co prism precursor was dispersed in 140 mL of ethanol, and then 140 mg of ammonium metavanadate was dispersed in 20 mL of deionized water, heated to dissolve; the aqueous solution was added dropwise to the ethanol solution , stirred in a water bath at 85 °C for 0.5 h, then centrifuged, washed and dried to obtain NiCo-VO x intermediate. NiCo-VO will be obtained x Take 80 mg and 80 mg of selenium powder as the intermediate, mix them evenly with a mortar, place them in a porcelain boat, heat them in a tube furnace to 300 °C, keep them...

Embodiment 2

[0032] Dissolve 600 mg of cobalt acetate and 1200 mg of nickel acetate in 80 mL of ethanol, and the resulting solution is solution A. Dissolve 3600 mg of polyvinylpyrrolidone in 280 mL of ethanol, and the resulting solution is solution B; Solution A was slowly poured into solution B, and stirred in a water bath at 100 °C for 2 h to obtain the precipitation of the Ni-Co prism precursor. After centrifugal washing and drying, 140 mg of the obtained Ni-Co prism precursor was dispersed in 140 mL of ethanol, and then 420 mg of ammonium metavanadate was dispersed in 28 mL of deionized water, heated and dissolved; the aqueous solution was added dropwise to the ethanol solution , stirred in a water bath at 100 °C for 2 h, then centrifuged, washed and dried to obtain NiCo-VO x intermediate. NiCo-VO will be obtained x Take 80 mg and 240 mg of selenium powder as the intermediate, mix them evenly with a mortar, place them in a porcelain boat, heat them in a tube furnace to 500 °C, keep t...

Embodiment 3

[0034] Dissolve 600 mg of cobalt acetate and 600 mg of nickel acetate in 75 mL of ethanol, and the resulting solution is solution A. Dissolve 3000 mg of polyvinylpyrrolidone in 200 mL of ethanol, and the resulting solution is solution B; Solution A was slowly poured into solution B, and stirred in a water bath at 85 °C for 4 h to obtain the precipitation of the Ni-Co prism precursor. After centrifugal washing and drying, 140 mg of the obtained Ni-Co prism precursor was dispersed in 140 mL of ethanol, and then 280 mg of ammonium metavanadate was dispersed in 24 mL of deionized water, heated and dissolved; the aqueous solution was added dropwise to the ethanol solution , stirred in a water bath at 90 °C for 4 h, then centrifuged, washed and dried to obtain NiCo-VO x intermediate. NiCo-VO will be obtained x The intermediate was mixed with 80 mg and 160 mg of selenium powder through a mortar, then placed in a porcelain boat, heated to 500 °C in a tube furnace, kept for 1 h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Photoelectric conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com