Tungsten sulfide doped cobalt copper sulfide counter electrode catalyst with hollow nanotube structure as well as preparation method and application thereof

An electrode catalyst, cobalt copper sulfide technology, applied in circuits, capacitors, photovoltaic power generation, etc., can solve the problems of limiting low-cost commercial applications, high electrode cost, easy corrosion, etc., to achieve excellent electrocatalytic performance, short reaction time, cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

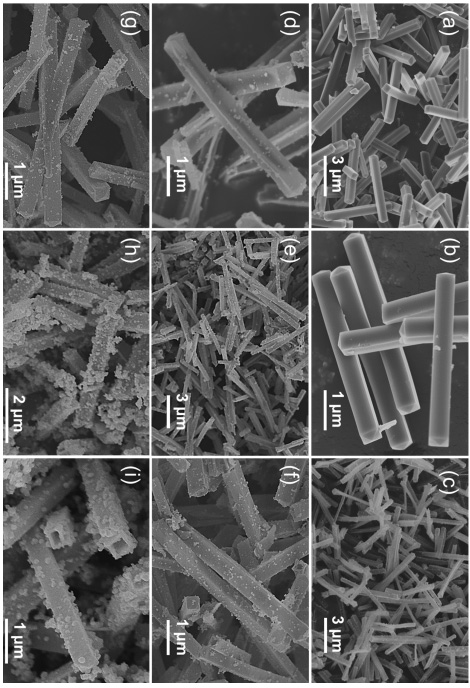

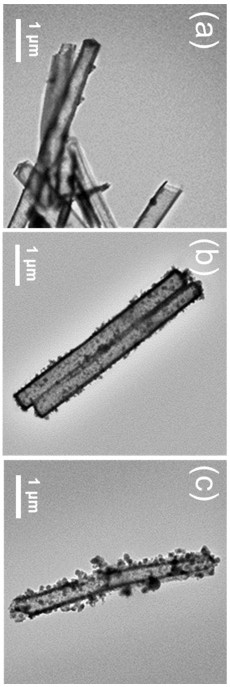

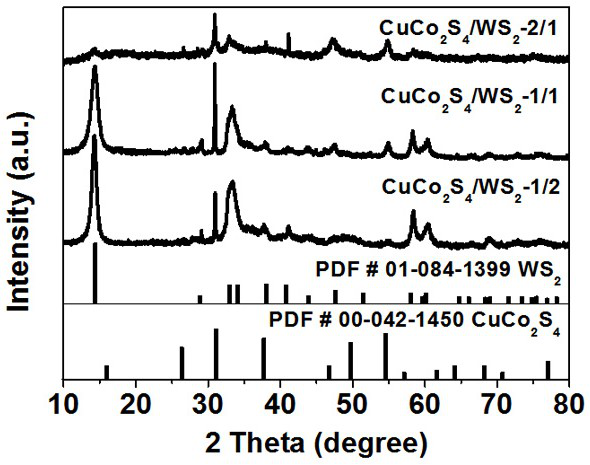

[0030] Dissolve 2.4 g of PVP in 180 mL of ethanol, and the resulting solution is solution A; dissolve 600 mg of cobalt acetate and 300 mg of copper acetate in 60 mL of ethanol solution, and the resulting solution is solution B. Solution B was slowly poured into solution A, and stirred in a water bath at 70 °C for 1 h to obtain Cu-Co nanotube precursor precipitation. After washing and drying the precipitated Cu-Co nanotube precursor obtained, 200 mg was dispersed in 60 mL of ethanol, and then 300 mg (NH 4 ) 2 WS 4 Dissolve in 20 mL deionized water; add the aqueous solution dropwise to the ethanol solution, stir at room temperature for 0.5 h, then centrifuge, wash and dry to obtain Cu-CoWS x . Cu-CoWS to be obtained x Take 150 mg and put it in a porcelain boat, in H 2 / Ar atmosphere was heated to 200 °C in a tube furnace, held for 1 h, and the heating rate was 1 °C / min, and finally the hollow nanotube structure tungsten sulfide doped cobalt copper sulfide CuCo 2 S 4 / WS ...

Embodiment 2

[0032] Dissolve 2.7 g of PVP in 180 mL of ethanol, and the resulting solution is solution A; dissolve 600 mg of cobalt acetate and 300 mg of copper acetate in 60 mL of ethanol solution, and the resulting solution is solution B. Solution B was slowly poured into solution A, and stirred in a water bath at 80 °C for 1 h to obtain Cu-Co nanotube precursor precipitation. After washing and drying the precipitated Cu-Co nanotube precursor obtained, 400 mg was dispersed in 60 mL of ethanol, and then 300 mg (NH 4 ) 2 WS 4 Dissolve in 15 mL deionized water; add the aqueous solution dropwise to the ethanol solution, stir at room temperature for 1 h, centrifuge, wash and dry to obtain Cu-CoWS x . Cu-CoWS to be obtained x Take 150 mg and put it in a porcelain boat, in H 2 / Ar atmosphere was heated to 200 °C in a tube furnace, held for 1.5 h, and the heating rate was 2 °C / min, and finally the hollow nanotube structure tungsten sulfide doped cobalt copper sulfide CuCo 2 S 4 / WS 2 Cou...

Embodiment 3

[0034] Dissolve 3.0 g of PVP in 180 mL of ethanol, and the resulting solution is solution A; dissolve 600 mg of cobalt acetate and 300 mg of copper acetate in 60 mL of ethanol solution, and the resulting solution is solution B. Solution B was slowly poured into solution A, and stirred in a water bath at 80 °C for 2 h to obtain Cu-Co nanotube precursor precipitation. After washing and drying the precipitated Cu-Co nanotube precursor obtained, 480 mg was dispersed in 60 mL of ethanol, and then 320 mg (NH 4 ) 2 WS 4 Dissolve in 12 mL deionized water; add the aqueous solution dropwise to the ethanol solution, stir at room temperature for 0.5 h, then centrifuge, wash and dry to obtain Cu-CoWS x . Cu-CoWS to be obtained x Take 150 mg and put it in a porcelain boat, in H 2 / Ar atmosphere was heated to 200 °C in a tube furnace, held for 1.5 h, and the heating rate was 3 °C / min, and finally the hollow nanotube structure tungsten sulfide doped cobalt copper sulfide CuCo 2 S 4 / WS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| open-circuit voltage | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com