Heat dissipation device based on continuous droplet liquid supplementation

A heat dissipation device and liquid replenishment technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of dry heating wall surface, inability to reduce the superheat of wall surface well, limited liquid replenishment capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

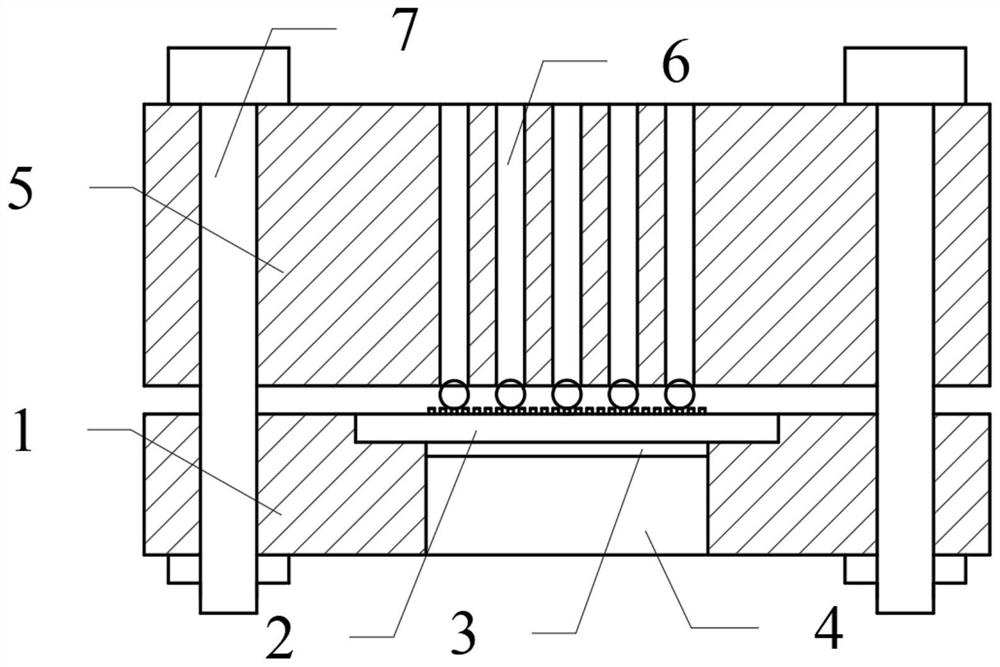

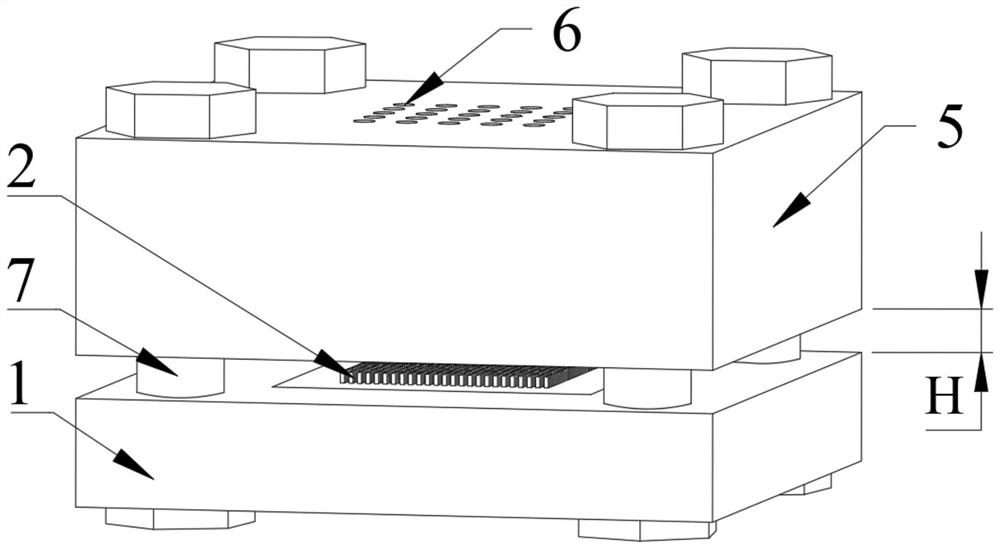

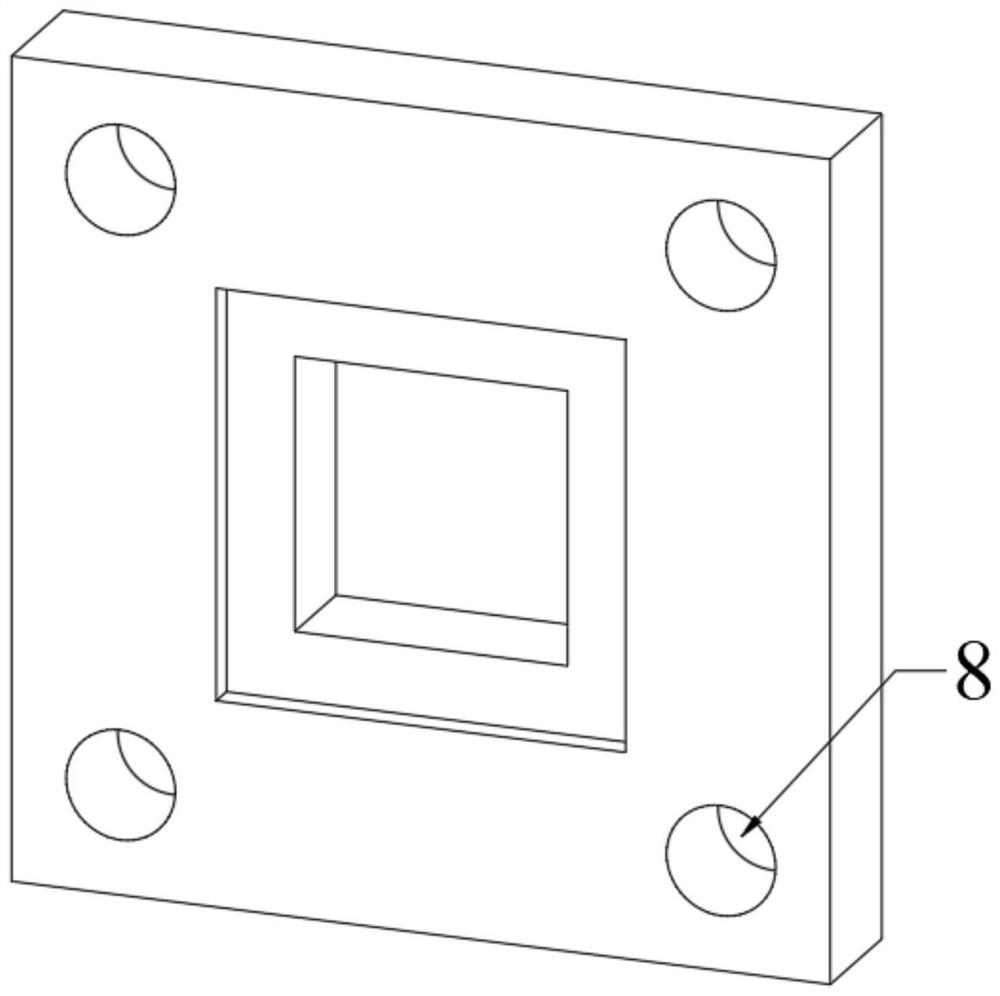

[0037] A heat dissipation device based on continuous liquid replenishment of droplets, such as Picture 1-1 , 1-2 As shown, it includes a lower substrate 1 , an evaporation-boiling capillary core 2 , an ITO heating film 3 , an insulating material 4 , a liquid replacement device 5 , a liquid replacement channel 6 , and a distance-adjustable stud 7 . An evaporation-boiling capillary wick 2 is arranged above the lower substrate 1, and an ITO heating film 3 is sputtered in the central area of the bottom thereof, through which the ITO heating film 3 provides heat for the evaporation-boiling capillary wick 2, and the evaporation-boiling capillary wick 2 acts as a heat source. The bottom of the ITO heating film 3 is filled with an insulating material 4 to prevent heat exchange with the external environment and heat loss. A liquid replenisher 5 is arranged above, and a plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com