Heating body structure suitable for ultra-high temperature and high pressure condition

A heating body and ultra-high temperature technology, applied in the direction of heating elements, heating element materials, ohmic resistance heating parts, etc., can solve the problems of tungsten wires that are easy to break, tungsten wires are not easy to replace, and winding is difficult, so as to facilitate large-scale production , easy to test and select, good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

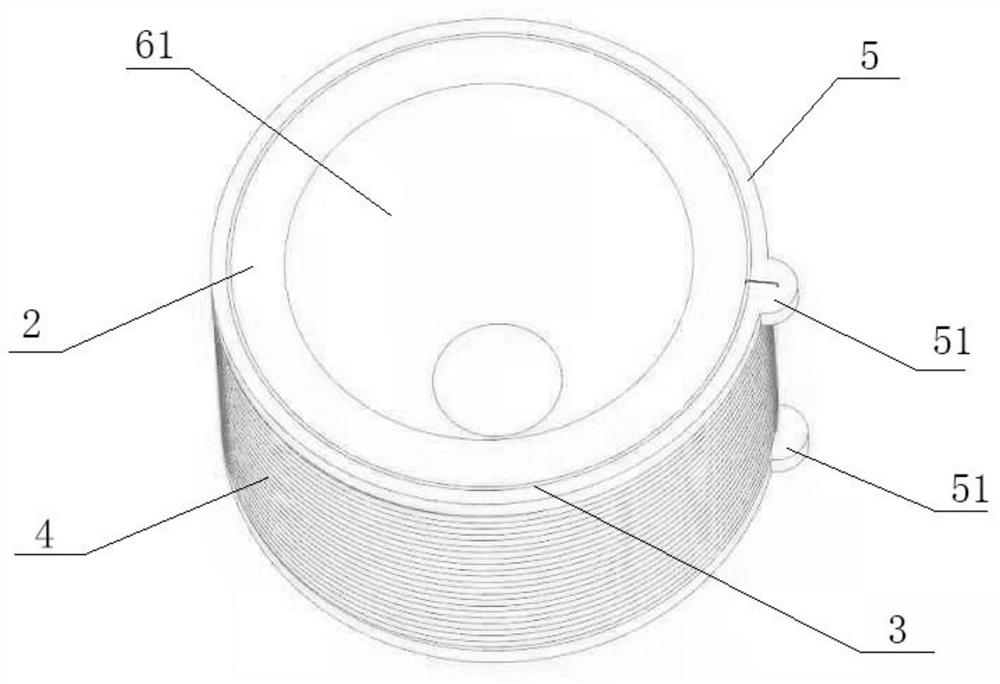

[0039] Such as figure 1 As shown, the heating body structure 1 suitable for ultra-high temperature and high pressure conditions, the heating body structure 1 includes a support component 2, and a heat generating component 4 bonded to the support component 2 through a heat conducting layer 3 and a heating component 4 electrically connected The electrode 5; the support member 2 is a zirconia ceramic support member, the support member is a cylindrical structure, and an annular limiter 6 is arranged inside the support member, and a substance that needs to be heated can be placed on the annular limiter 6; A heat conduction layer 3 is arranged on the outside of the support member, and the heat conduction layer 3 is bonded to the support member 2 and the heat-generating component 4 and has good thermal conductivity; the heat-generating component 4 is made of graphite or silicon carbide material at one time, and the heat-generating The component 4 is bonded around and attached to the ...

Embodiment 2

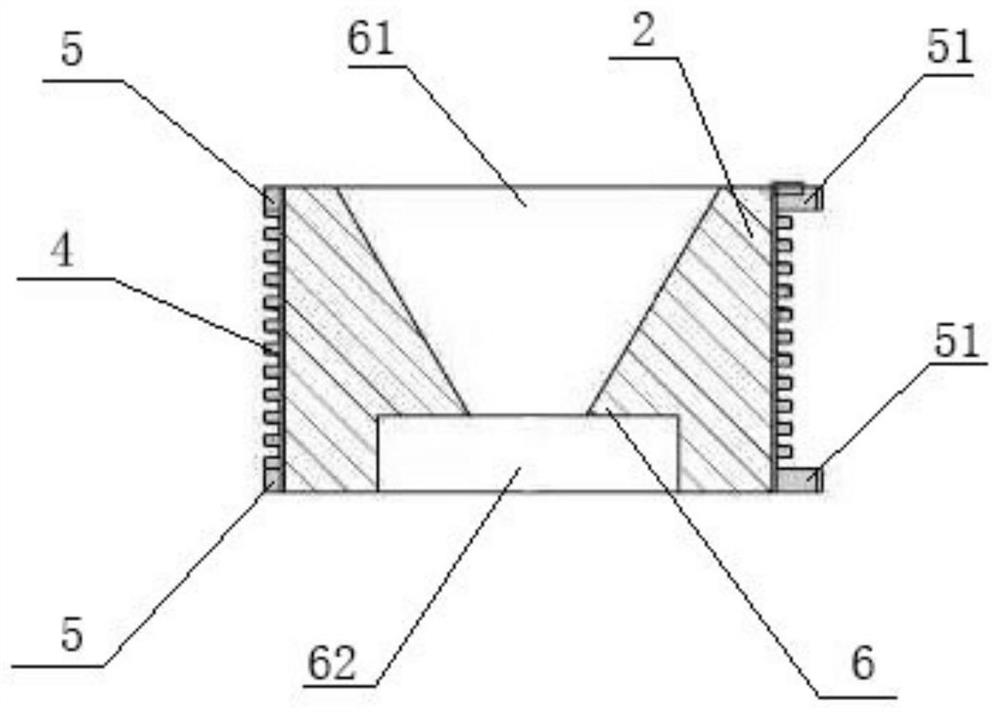

[0041] Such as figure 2 As shown, on the basis of Embodiment 1, the annular stopper 6 forms two connected chambers inside the cylindrical structure, one of which is a conical chamber 61 and the other is a cylindrical chamber 62. According to the Depending on the shape and size of the material to be processed, different chambers can be selected. The heat conduction layer 3 is an aluminum nitride heat conduction layer. The heat generating component 4 is spirally wound on the outside of the supporting component.

Embodiment 3

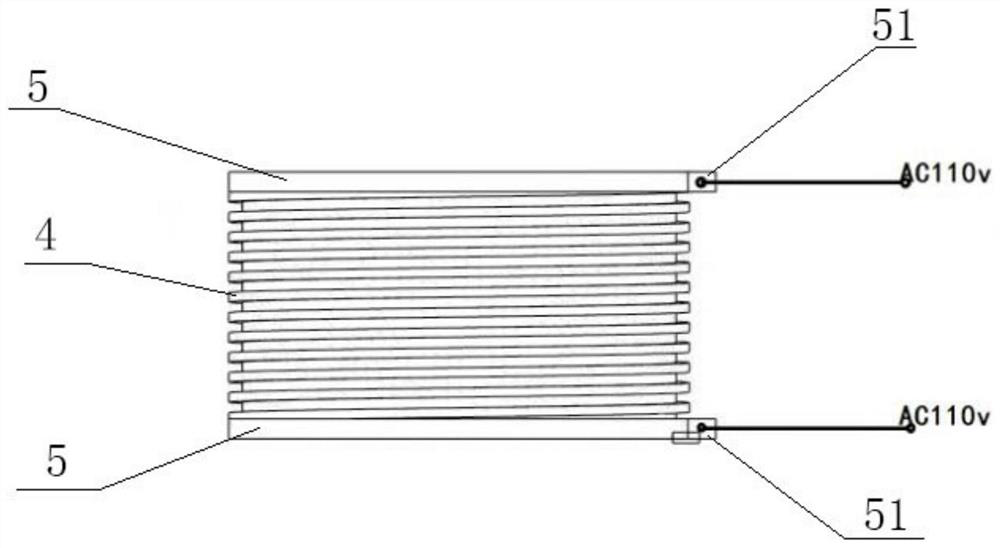

[0043] On the basis of Embodiment 1, the heating component 4 can be made of silicon carbide, and the resistance is preferably 6Ω. The height of the support member 2 is 4mm. The silicon carbide material is pressed into a spiral silicon carbide wire, the diameter of the silicon carbide wire is less than or equal to 0.5mm, and the silicon carbide wire is wound spirally on the outside of the support member 2, and adhered to the outer wall of the support member through an aluminum nitride heat conducting layer. The wire pitch of the silicon carbide filament helix is greater than 0.5mm.

[0044] The resistance of the heating element 4 in embodiment 3 is 6Ω, as image 3 As shown, through 110V AC pulse voltage, the power can reach up to 2kw, the working temperature can reach 1200 ℃, and its power can be precisely controlled by computer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Line spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com