Whole machine room unified monitoring platform and method suitable for machine room chip-level heat pipe liquid cooling

A chip-level, liquid-cooled technology, applied in the direction of measuring devices, cooling/ventilation/heating transformation, casing/cabinet/drawer components, etc., can solve problems that cannot meet the needs of operation safety monitoring and green consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061]As a preferred embodiment, the operating state amount is the state logic value of the monitored object, including boot and shutdown, line high pressure alarm, pipeline high and low voltage lock, voltage current overload, motor overload, communication failure, power input and output status, alarm status Functional data is a instantaneous value of the monitoring objects, including temperature, humidity, voltage, current, power, frequency, speed, torque, load rate, and the like.

[0062]Specifically, the operating status amount refers to the status logic value of the object being monitored, such as booting and shutdown, pipeline high pressure alarm, pipeline high and low voltage lock, voltage current overload, motor overload, communication failure, power supply input and output status, alarm status Wait, the logic value is typically 1 or 0; functional data refers to the operation data indicator of the monitored object, such as temperature, humidity, voltage, current, power, frequenc...

Embodiment 1

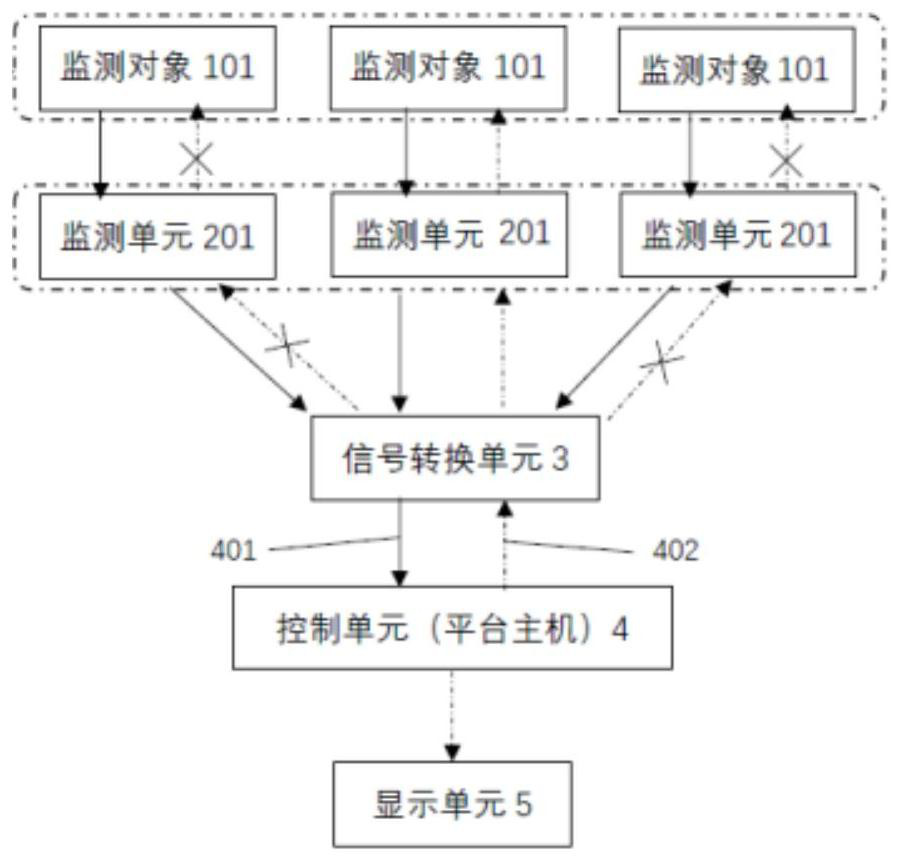

[0093]figure 1 A block diagram of a unified monitoring platform suitable for use in a machine room chip-level heat pipe is shown in accordance with one embodiment of the present invention.

[0094]Such asfigure 1 As shown, the full machine room for the machine room chip-level heat pipe is suitable, including: monitoring object 101, monitoring unit 201, signal conversion unit 3, control unit 4, display unit 5; monitoring object 101 includes IT cabinet server equipment , Precision air conditioning equipment, power and humidity in distribution equipment, video security equipment, machine room, chip-level heat pipe operation, machine room and cabinet leakage, liquid cooling power equipment, liquid cold pipe water supply back water data, outdoor atmosphere Parameter, power consumption data, real-time energy consumption PUE data; monitoring unit 201 includes multiple sub-monitor modules, including IT server group communication modules, air conditioning communication modules, distributor acqu...

Embodiment 2

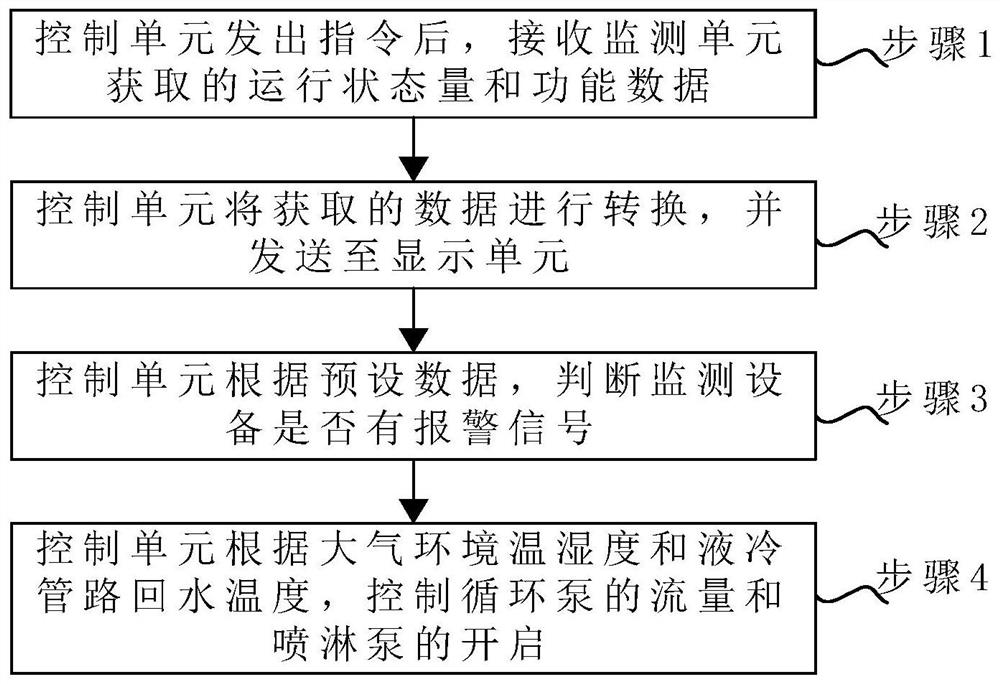

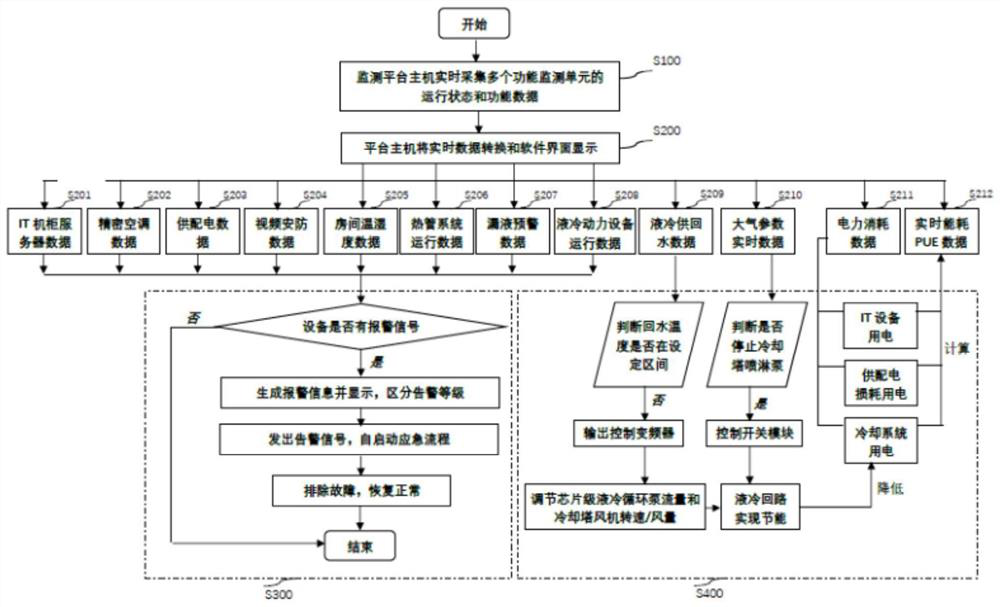

[0105]figure 2 A flow chart showing a unified monitoring method suitable for a machine room chip-level heat pipe cooling in accordance with one embodiment of the present invention.image 3A detailed flow chart showing a unified monitoring method suitable for a machine room chip-level heat pipe cooling in accordance with one embodiment of the present invention.

[0106]Combinefigure 2 withimage 3As shown, the whole machine room for the machine room chip-level heat pipe is used, including:

[0107]Step 1, after the control unit issues an instruction, receive the operating status quantity and functional data acquired by the monitoring unit;

[0108]Step 2, the control unit converts the acquired data and transmits to the display unit;

[0109]Step 3, the control unit determines whether the monitoring device has alarm signal according to the preset data;

[0110]Step 4, the control unit controls the flow rate of the circulation pump and the opening of the spray pump in accordance with the temperature an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com