Microwave methods for converting hydrocarbon-based waste materials into oil and gas fuels

A technology that transforms into microwave cavities, applied in the field of plastic pyrolysis system and plastic waste pyrolysis system, can solve the elusive problems of energy efficiency and sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

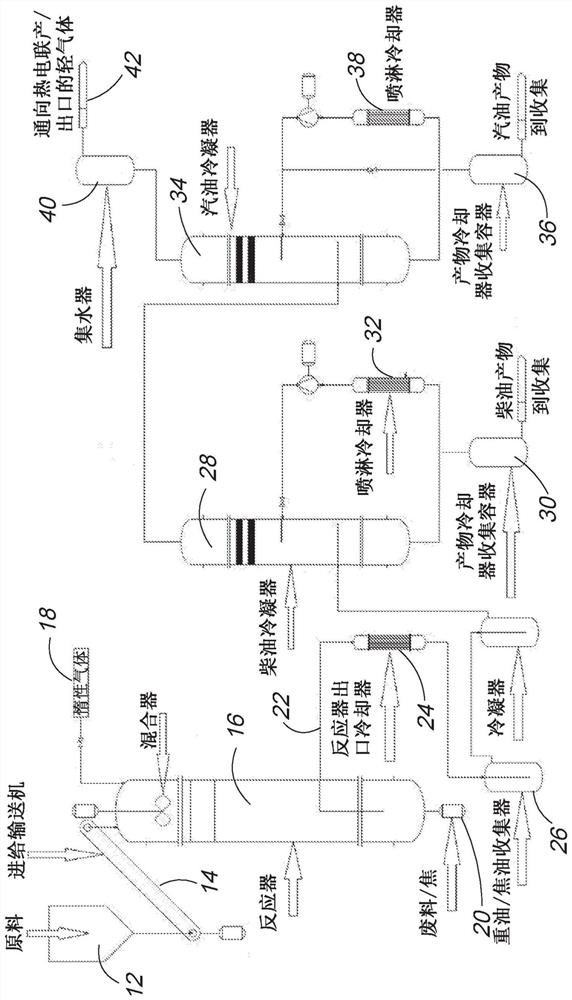

[0027] first reference Figure 1A , wherein there is shown a new and improved method and system for converting hydrocarbon-based waste into hydrocarbon fuels, the system generally indicated herein at 10 in this schematic diagram.

[0028] Figure 1A is a highly schematic level process flow diagram showing the main functional components of the system, highlighting the main sub-component systems. When ready for processing, in one embodiment, material is fed from material hopper 12 into mechanical conveyor 14 at ambient temperature while maintaining an optimal feed rate. In another embodiment, the raw material may be fed into the conveyor at an elevated melt temperature, also maintaining an optimal feed rate. When feeding at elevated temperatures, an extruder is employed to ensure a smooth flow of material into the reactor. Furthermore, in an embodiment, the heated feedstock is cooled to a temperature between 30°C and 50°C prior to introduction into the reactor to reduce the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com