High-fluidity and high-gloss polypropylene composition and preparation method thereof

A polypropylene composition and high-fluidity technology, applied in the field of high-fluidity and high-gloss polypropylene composition and its preparation, can solve the problems of complicated and expensive modifiers and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

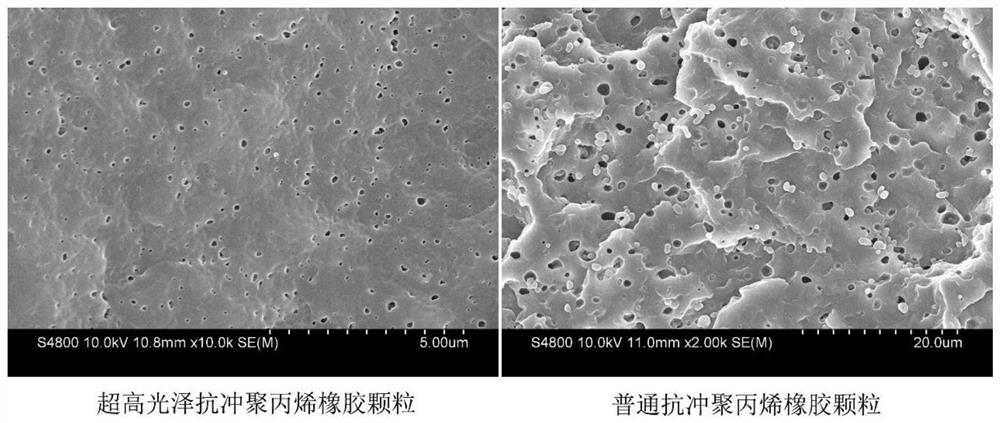

Embodiment 1

[0050] Using propylene as raw material, feeding 30 tons per hour, the catalyst titanium tetrachloride, carrier MgCl 2 , electron donor isobutyldimethoxysilane and cocatalyst triethylaluminum are added to the loop reactor, and 2kg of catalyst is entered per hour, and the control Al / Mg=4, Al / Si=4 controls the loop reactor The reaction pressure is 3.4MPa, the reaction temperature is 70°C, and the hydrogen concentration in the reactor is 0.26%, to obtain a polypropylene slurry. The polypropylene slurry material enters the gas phase reactor, and the reaction pressure of the gas phase reactor is controlled to be 1.2MPa, the reaction temperature is 68°C, and the ethylene concentration in the reactor is controlled to be 6%. The block copolymerized polypropylene powder is 11.8wt%, the ethylene content is 2.9wt%, and the particle size distribution of ethylene-propylene rubber is 10-300nm. Take by weight 100 parts of block copolymerized polypropylene (see figure 1 ), 0.1 part of nuclea...

Embodiment 2

[0052] Using propylene as raw material, feeding 30 tons per hour, the catalyst titanium tetrachloride, carrier MgCl 2 , electron donor isobutyldimethoxysilane and cocatalyst triethylaluminum are added to the loop reactor, and 2kg of catalyst is entered per hour, and the control Al / Mg=4, Al / Si=4 controls the loop reactor The reaction pressure is 3.4MPa, the reaction temperature is 70°C, and the hydrogen concentration in the reactor is 0.25%, to obtain a polypropylene slurry. The polypropylene slurry material enters the gas phase reactor, and the reaction pressure of the gas phase reactor is controlled to be 1.2MPa, the reaction temperature is 68°C, and the ethylene concentration in the reactor is controlled to be 6.2%. The block copolymerization polypropylene powder is 7.7wt%, ethylene content 2.0wt%, ethylene propylene rubber particle size distribution in 10-250nm. Weigh 100 parts of block copolymer polypropylene, 0.1 part of nucleating agent substituted sodium aryl phosphate...

Embodiment 3

[0054] Using propylene as raw material, feeding 30 tons per hour, the catalyst titanium tetrachloride, carrier MgCl 2 , electron donor isobutyldimethoxysilane and cocatalyst triethylaluminum are added to the loop reactor, and 2kg of catalyst is entered per hour, and the control Al / Mg=4, Al / Si=4 controls the loop reactor The reaction pressure is 3.4MPa, the reaction temperature is 70°C, and the hydrogen concentration in the reactor is 0.25%, to obtain a polypropylene slurry. The polypropylene slurry enters the gas phase reactor, the reaction pressure of the gas phase reactor is controlled to be 1.2MPa, the reaction temperature is 68°C, the ethylene concentration in the reactor is controlled to be 6.4%, and the melt flow rate is 28.7g / 10min, the content of ethylene-propylene rubber is The block copolymerization polypropylene powder is 5.2wt%, ethylene content 1.6wt%, ethylene propylene rubber particle size distribution in 10-200nm. Weigh 100 parts of block copolymer polypropyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com