Dispersion-strengthened high-silicon aluminum alloy and preparation method thereof

A high-silicon aluminum alloy, dispersion-strengthening technology, applied in additive manufacturing, additive processing, etc., can solve the problems of difficult to effectively improve high-temperature strength, decreased thermal conductivity, poor batch stabilization, etc., to improve service reliability, improve Effects of room temperature and high temperature strength, good thermal conductivity and coefficient of thermal expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

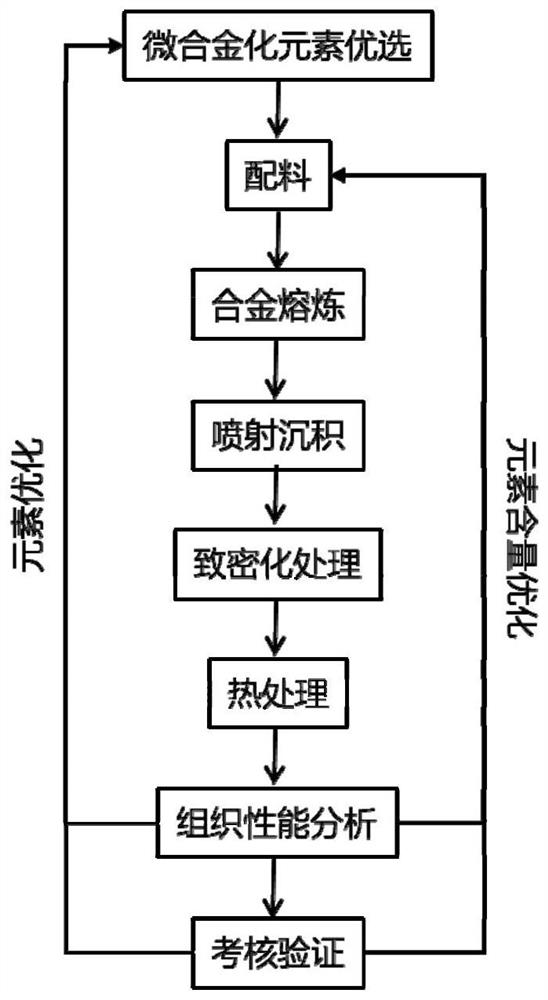

[0031] The present invention also provides a method for preparing a dispersion-strengthened high-silicon aluminum alloy, please refer to figure 1 , figure 1 A flow chart of the preparation process of the dispersion-strengthened high-silicon aluminum alloy of the present invention. Specifically include the following steps:

[0032] S1: Select microalloying elements.

[0033] S2: Spray-deposited alloy melt: Weigh the microalloy elements and Al-Si alloy matrix according to the metering ratio, and perform melting, slagging and degassing to obtain an alloy melt, and then obtain a spray-deposited ingot through high-pressure atomization and deposition Blank.

[0034] Preferably, the microalloying element is selected from an aluminum master alloy, and the content of the microalloying element in the master alloy is not more than 10%; the melting temperature should be 200-300°C higher than the melting point of the alloy melt.

[0035] S3: Densification treatment: performing densific...

Embodiment 1

[0046] A kind of Al-12Si-0.6Mo alloy is prepared in this embodiment, please refer to the attached figure 1 , figure 1 It is a flow chart of the preparation process of the dispersion-strengthened high-silicon aluminum alloy of the present invention, and the specific steps are as follows:

[0047] S1: Selection of microalloying elements: combined with binary and ternary alloy phase diagrams, and solid solubility and diffusion coefficients of different elements in aluminum, the preferred microalloying elements have a limit solid solubility in aluminum of less than 0.6wt%, The solid solubility at room temperature is less than 0.1wt%, and the diffusion coefficient is less than 8.0×10 -15 cm 2 / s, and the melting point of the dispersion strengthening phase formed by microalloying elements and aluminum and / or silicon is higher than the eutectic temperature of the Al-Si alloy matrix, that is, 577°C; aiming at the microstructure, performance, service environment and structural charac...

Embodiment 2

[0055] The preparation steps of the dispersion-strengthened high-silicon aluminum alloy in this embodiment 2 are the same as those in the embodiment 1, the difference lies in the content of each component and the process condition parameters in the preparation process.

[0056] In this embodiment, a kind of Al-27Si-0.5V is prepared, and the specific steps are as follows:

[0057] S1: Selection of microalloying elements: combined with binary and ternary alloy phase diagrams, and solid solubility and diffusion coefficients of different elements in aluminum, the preferred microalloying elements have a limit solid solubility in aluminum of less than 0.6wt%, The solid solubility at room temperature is less than 0.1wt%, and the diffusion coefficient is less than 8.0×10 -15 cm 2 / s, and the melting point of the dispersion strengthening phase formed by microalloying elements and aluminum and / or silicon is higher than the eutectic temperature of the Al-Si alloy matrix, that is, 577°C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com