Preparation method of oiling agent emulsion for carbon fiber precursor

A technology of carbon fiber precursor and manufacturing method, which is applied in the field of carbon fiber manufacturing, can solve problems such as high equipment cost, high energy cost, and affecting quality and grade, and achieve the effect of reducing production cost and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0122] Process 1: Preparatory Mixing Process

[0123] Mix other components except water according to the ratio shown in Table 1, and use a paddle stirrer with a tip speed of 0.53m / s to stir and mix to obtain an oil composition.

[0124] Process 2: Emulsification Process

[0125] Add deionized water within 10 seconds to the oil mixture obtained in process 1 while stirring at the blade tip speed of 0.53m / s, and adjust its concentration to 49%. After adding water, continue stirring for 120 minutes to obtain an O / W type emulsion. Its particle size is 490 nm.

[0126] Process 3: Dilution process

[0127] Dilute the emulsion obtained in process 2 to 30% with water, and obtain the oil treatment liquid for carbon fiber precursors, the particle size of which is 480nm.

[0128] Table 1

[0129]

[0130] The details of each compound used in the experimental example and the comparative example are as follows:

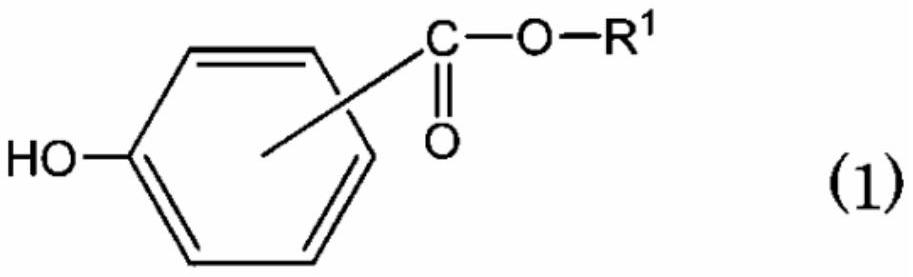

[0131] Hydroxybenzoic acid ester (ingredient A): in the aforementione...

experiment example 2、4、6

[0144] The oil agent composition and the process conditions of process 2 were changed as shown in Table 2 and Table 3, and the other conditions were the same as in Example 1 to obtain the oil agent treatment liquid.

experiment example 3、5

[0146] The oil composition and the conditions of process 2 were changed as shown in Table 3. The nonionic surfactant was not added in process 1, but was first dissolved in deionized water in process 2, and then added with water, and the remaining conditions In the same manner as in Example 1, an oil treatment liquid was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com