Method for making seafood sauce from squid leftovers

A technology of seafood sauce and leftovers, applied in the field of food processing, can solve the problems of low utilization efficiency and economic value, waste of squid leftovers, etc., to avoid high concentrations of heavy metals and biogenic amines, reduce fishy smell, and promote comprehensive utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Present embodiment provides a kind of method utilizing squid leftovers to make seafood sauce, comprises the steps:

[0047] (1) Smash squid viscera and squid skin at a mass ratio of 1:1, and then add water at a volume ratio of 1:1 to obtain a slurry.

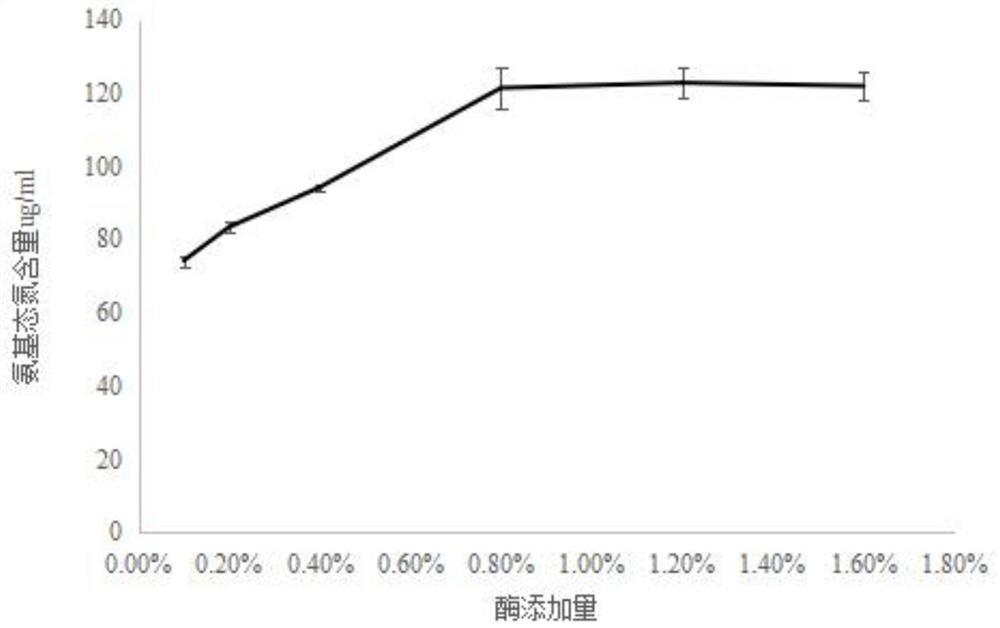

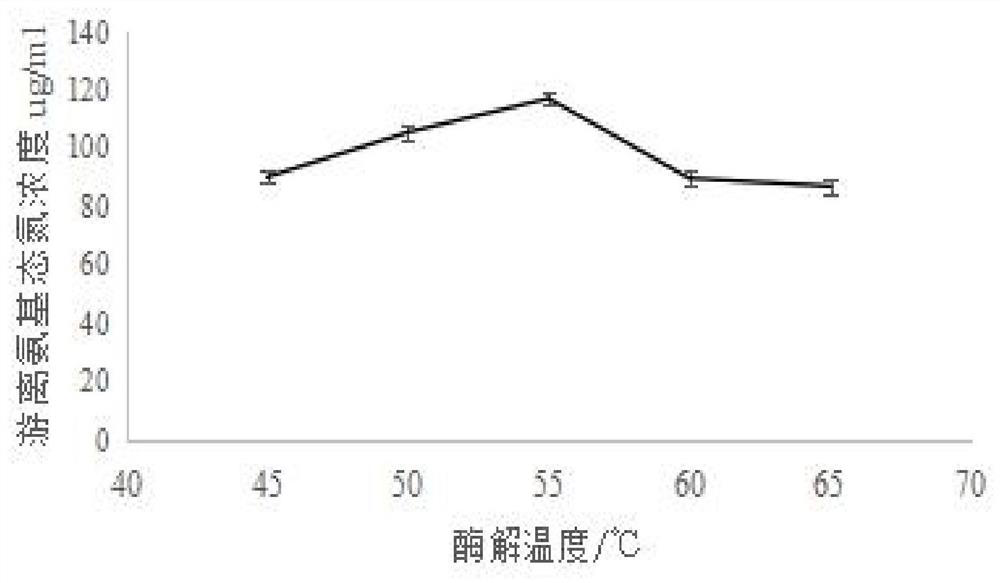

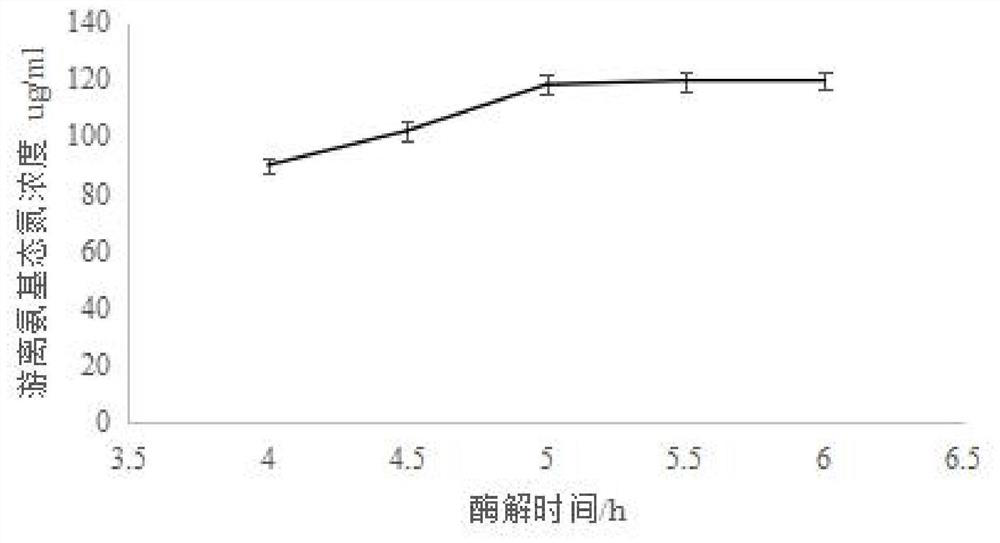

[0048] (2) Add enzyme to the above slurry for enzymolysis, inactivate enzyme, separate solid from liquid, and collect supernatant. The enzymolysis conditions are: the enzyme is a mixed enzyme of alkaline protease and flavor protease, the addition amount is 0.8% (mass fraction), the mass ratio of alkaline protease and flavor protease is 2:1, the enzymolysis time is 5h, and the enzymolysis temperature 50°C, pH=7.0. After 5.5 hours of enzymatic hydrolysis, heat and boil at 100°C for 6 minutes to inactivate the enzyme, then filter the enzymatic hydrolysis solution, and collect the supernatant.

[0049] (3) adjust the pH to 7.0, add D-xylose 3%, L-glutamic acid 2%, after stirring, carry out the Maillard aroma-generating reac...

Embodiment 2

[0058] Present embodiment provides a kind of method utilizing squid leftovers to make seafood sauce, comprises the steps:

[0059] (1) Smash squid viscera and squid skin at a mass ratio of 1:1, and then add water at a volume ratio of 1:1 to obtain a slurry.

[0060] (2) Add enzyme to the above slurry for enzymolysis, inactivate enzyme, separate solid from liquid, and collect supernatant. The enzymolysis conditions are: the enzyme is a mixed enzyme of alkaline protease and flavor protease, the addition amount is 0.8% (mass fraction), the mass ratio of alkaline protease and flavor protease is 2:1, the enzymolysis time is 5h, and the enzymolysis temperature 55°C, pH=7.0. After enzymolysis for 5 hours, heat and boil at 100°C for 6 minutes to inactivate the enzyme, then filter the enzymolysis solution and collect the supernatant.

[0061] (3) Add 50% volume of activated carbon to the supernatant after oscillating adsorption treatment, then centrifuge again to obtain the supernata...

Embodiment 3

[0082] Present embodiment provides a kind of method utilizing squid leftovers to make seafood sauce, comprises the steps:

[0083] (1) Smash squid viscera and squid skin at a mass ratio of 1:1, and then add water at a volume ratio of 1:1 to obtain a slurry.

[0084] (2) Add enzyme to the above slurry for enzymolysis, inactivate enzyme, separate solid from liquid, and collect supernatant. The enzymolysis conditions are: the enzyme is a mixed enzyme of alkaline protease and flavor protease, the addition amount is 0.4% (mass fraction), the mass ratio of alkaline protease and flavor protease is 2:1, the enzymolysis time is 5h, and the enzymolysis temperature 55°C, pH=7.0. After enzymolysis for 5 hours, heat and boil at 100°C for 6 minutes to inactivate the enzyme, then filter the enzymolysis solution and collect the supernatant.

[0085] (3) Add 50% volume of activated carbon to the supernatant after oscillating adsorption treatment, then centrifuge again to obtain the supernata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com