A feed processing device

A technology of feed processing and discharge board, which is applied in the direction of feed, solid separation, cleaning methods and utensils, etc., can solve the problems of not meeting the requirements of fine processing of locust leaf powder, deteriorating quality of locust leaf powder, and easy to block the filter screen, etc. Achieve the effect of improving grinding efficiency, strengthening crushing effect and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

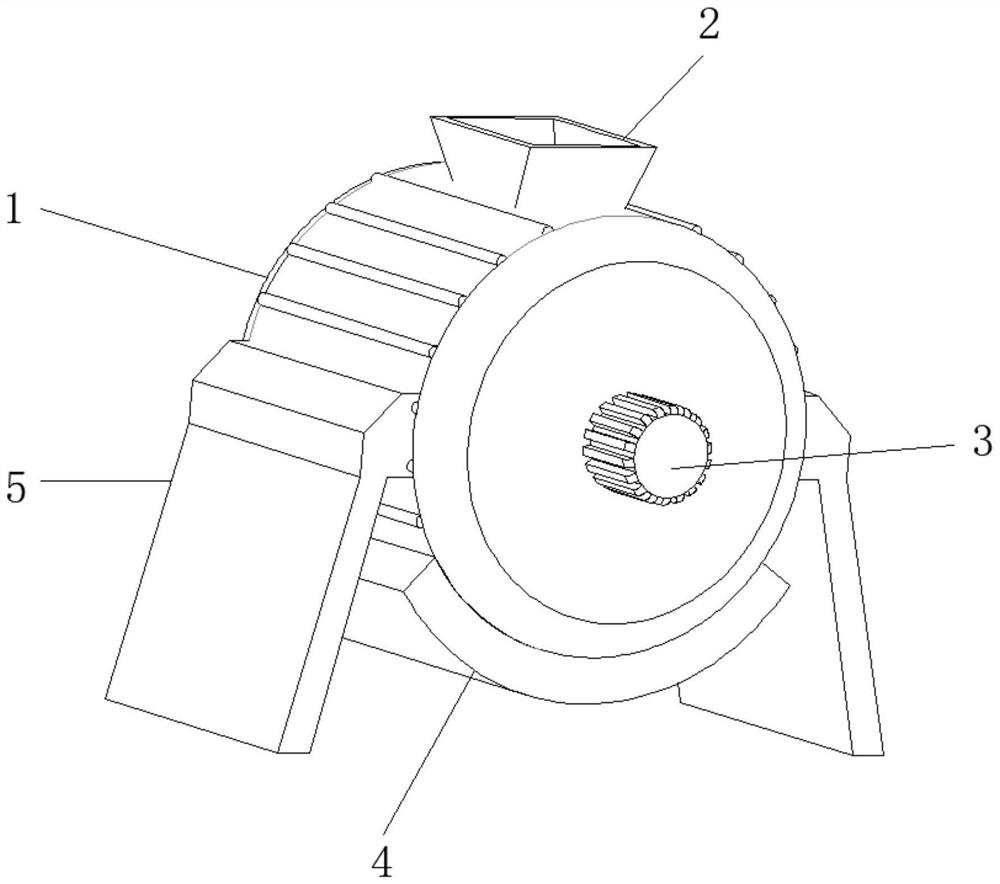

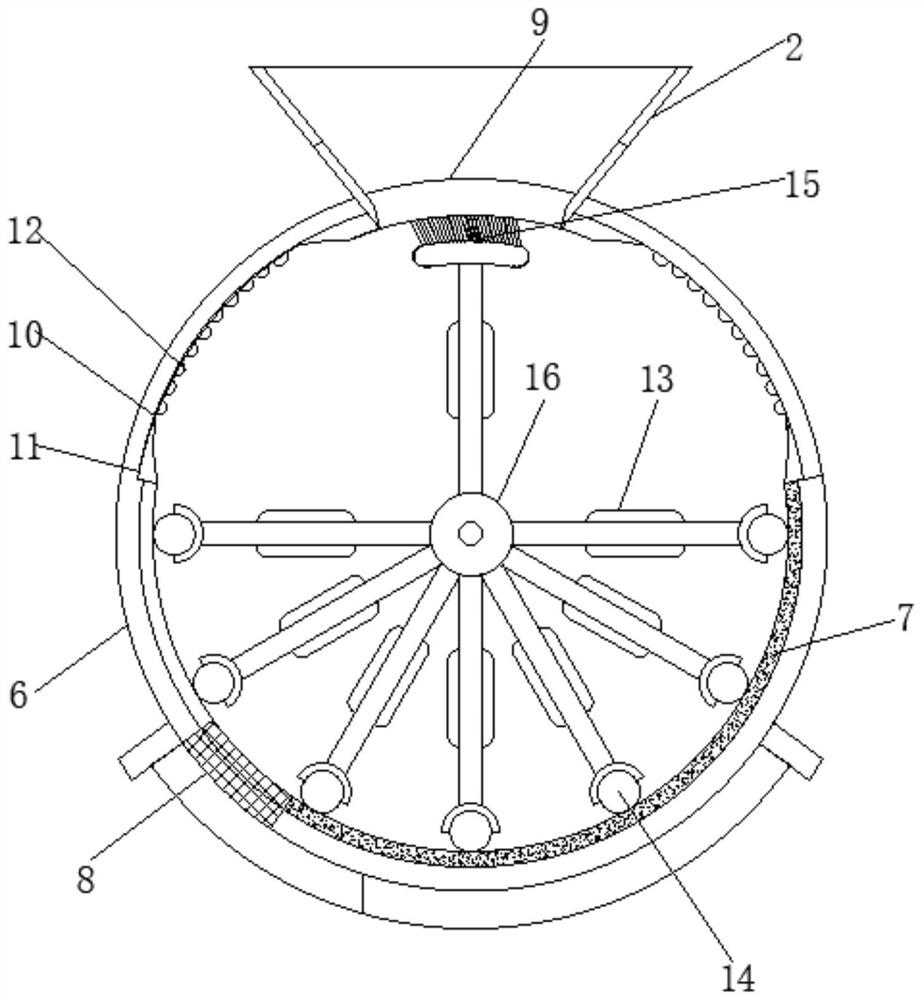

[0030] as Figure 1-7 As shown, embodiments of the present invention provides a feed processing apparatus, comprising a grinder body 1, an infeed hopper 2, an outlet plate 4, a support plate and a rotating motor 3, the top outer wall of the grinder body 1 is provided with an inlet groove, and the inner wall of the feed tank is welded to the feed hopper 2, the support plate is fixed by a screw to the outer wall at both ends of the grinder body 1, one side of the grinder outer wall is fixedly connected to the rotating motor 3, and the output shaft of the rotating motor 3 is connected to the hinge 16 through the coupling, and the discharge plate 4 is set at the bottom of the grinder body 1, And the outer wall of one end of the discharge plate 4 is opened with an outlet groove.

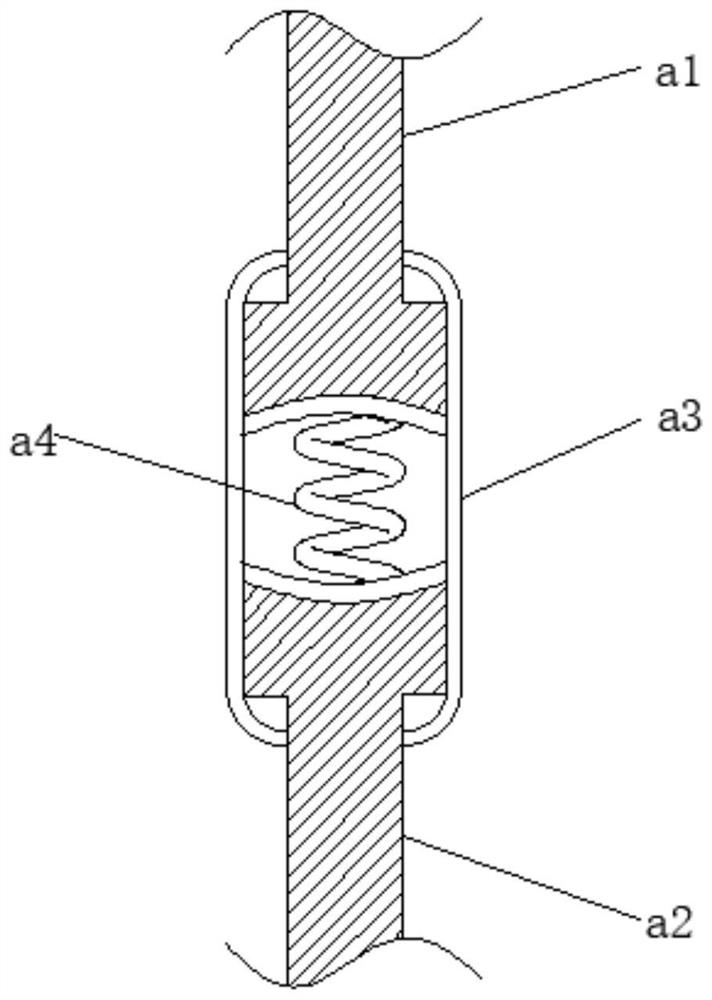

[0031] In the present invention, the grinder body 1 includes a barrel wall 6, and the bottom end of the barrel wall 6 inner wall is provided with a grinding layer 7, the outer wall of the bottom end of the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com