Bacteriostatic carpet fabric and preparation method thereof

A carpet and fabric technology, applied in the field of textile materials, can solve the problems of reducing product life, failing to achieve long-term antibacterial, and easy loss of antibacterial type.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

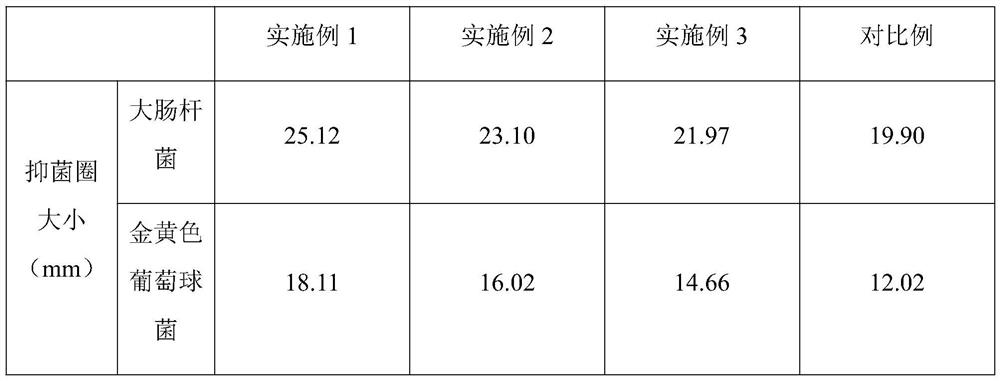

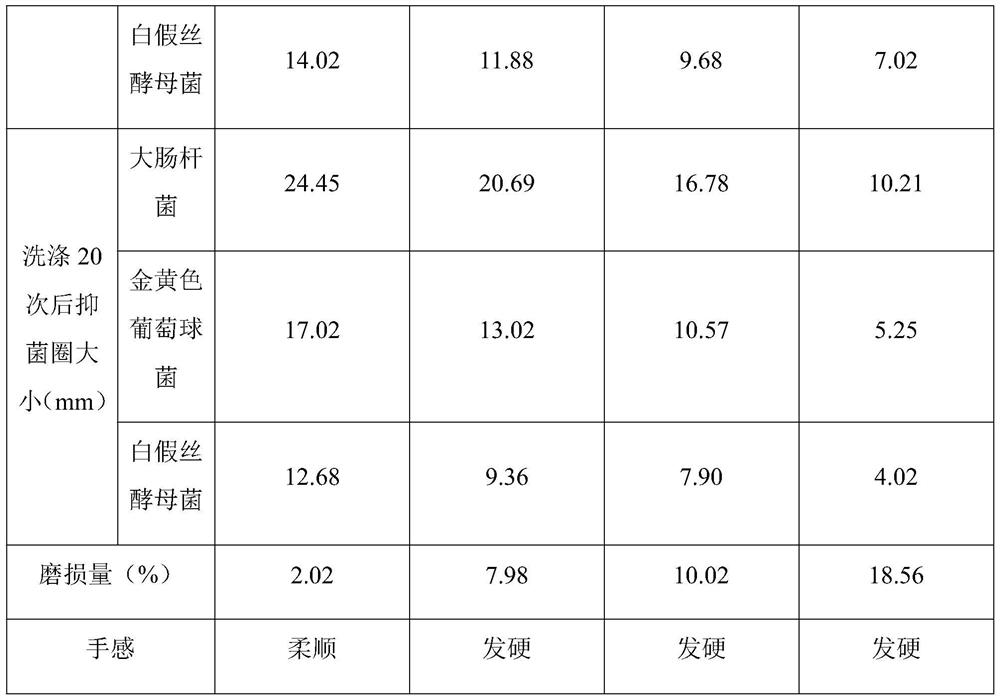

Embodiment 1

[0036] An antibacterial carpet fabric mainly comprises, by weight, 90 parts of pretreated carpet fabric, 15 parts of modified zinc oxide and 5 parts of zinc oxide nanocolumns.

[0037] A kind of preparation method of antibacterial carpet fabric, the preparation method of described antibacterial carpet fabric mainly comprises following preparation steps:

[0038](1) the carpet fabric and the protease solution with a mass fraction of 4% are mixed according to a mass ratio of 1:15, and the temperature is 70° C., and the pH is 7.5 after stirring and reacting for 2 hours, and then filtered to obtain a pretreated carpet fabric blank. The pretreated carpet fabric blank is elastically dried at a temperature of 130° C. for 35 minutes to obtain a pretreated carpet fabric;

[0039] (2) Mix the nano-sheet zinc oxide and the dopamine aqueous solution whose mass fraction is 1g / L in a beaker at a mass ratio of 1:12, ultrasonically disperse for 9 minutes, and add a nano-sheet zinc oxide mass ...

Embodiment 2

[0047] An antibacterial carpet fabric mainly comprises, by weight, 90 parts of pretreated carpet fabric, 15 parts of modified zinc oxide and 5 parts of zinc oxide nanocolumns.

[0048] A kind of preparation method of antibacterial carpet fabric, the preparation method of described antibacterial carpet fabric mainly comprises following preparation steps:

[0049] (1) the carpet fabric and the protease solution with a mass fraction of 4% are mixed according to a mass ratio of 1:15, and the temperature is 70° C., and the pH is 7.5 after stirring and reacting for 2 hours, and then filtered to obtain a pretreated carpet fabric blank. The pretreated carpet fabric blank is elastically dried at a temperature of 130° C. for 35 minutes to obtain a pretreated carpet fabric;

[0050] (2) Mix the nano-sheet zinc oxide and the dopamine aqueous solution whose mass fraction is 1g / L in a beaker at a mass ratio of 1:12, ultrasonically disperse for 9 minutes, and add a nano-sheet zinc oxide mass...

Embodiment 3

[0057] An antibacterial carpet fabric mainly comprises, by weight, 90 parts of pretreated carpet fabric, 15 parts of modified zinc oxide and 5 parts of zinc oxide nanocolumns.

[0058] A kind of preparation method of antibacterial carpet fabric, the preparation method of described antibacterial carpet fabric mainly comprises following preparation steps:

[0059] (1) the carpet fabric and the protease solution with a mass fraction of 4% are mixed according to a mass ratio of 1:15, and the temperature is 70° C., and the pH is 7.5 after stirring and reacting for 2 hours, and then filtered to obtain a pretreated carpet fabric blank. The pretreated carpet fabric blank is elastically dried at a temperature of 130° C. for 35 minutes to obtain a pretreated carpet fabric;

[0060] (2) Mix nano-zinc oxide and dopamine aqueous solution with a mass fraction of 1 g / L in a beaker at a mass ratio of 1:12, ultrasonically disperse for 9 minutes, and add trihydroxyl triol with a mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com