Thin-film lithium niobate electrooptical modulator and preparation method thereof

An electro-optic modulator and lithium niobate technology, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of high manufacturing process requirements, high difficulty, and high driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

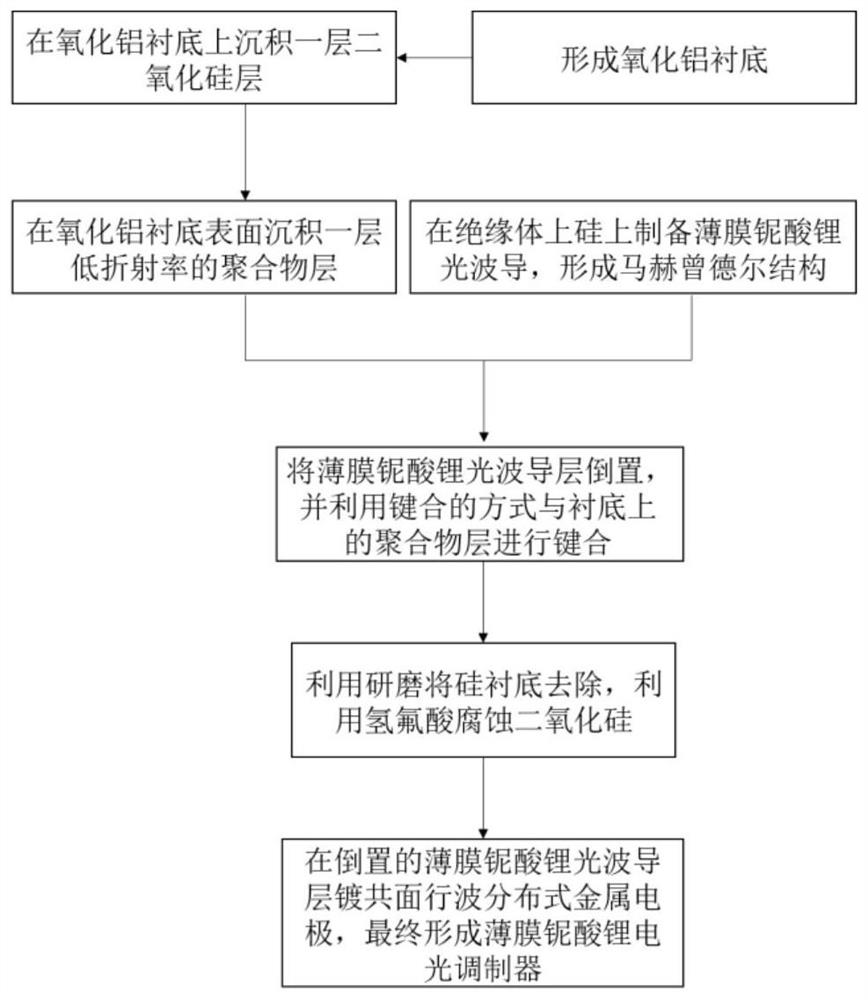

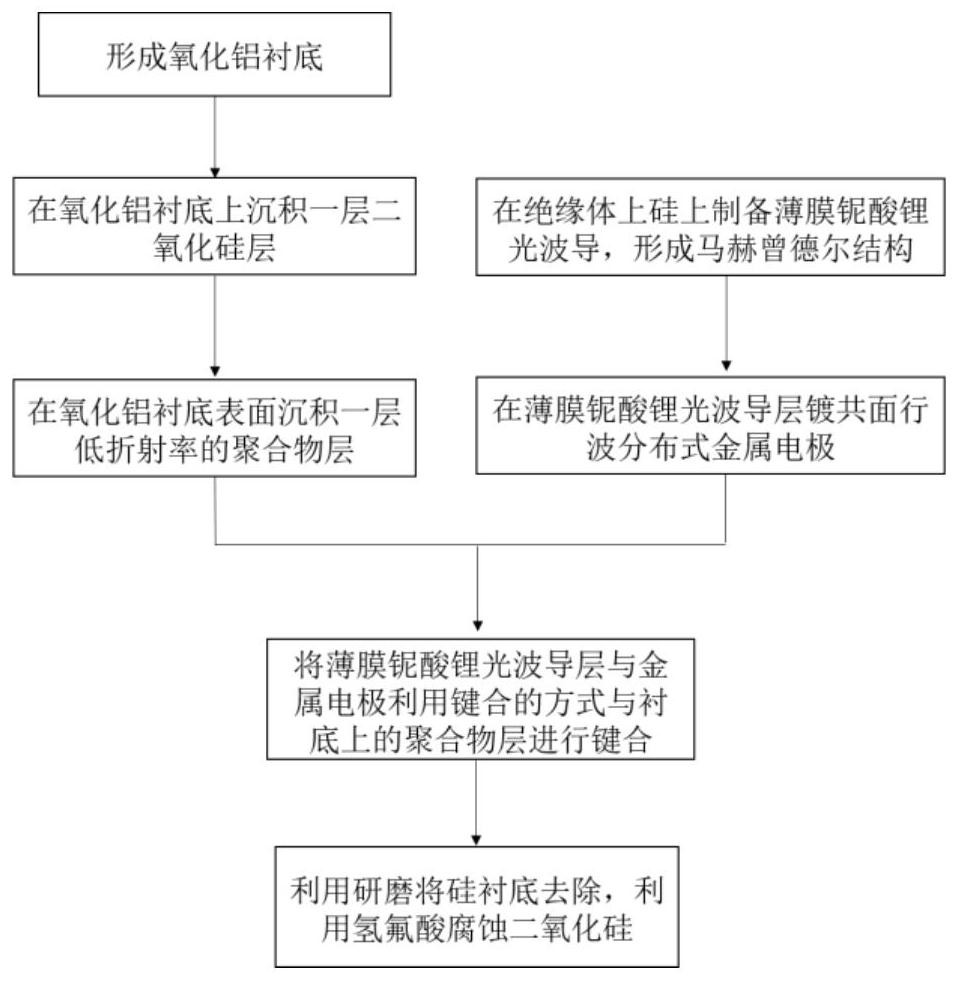

Method used

Image

Examples

Embodiment 1

[0066] Such as Figure 8 As shown, this embodiment includes a substrate 1, a buried oxide layer 2, a polymer layer 3 and an optical waveguide layer 4 arranged sequentially from bottom to top, [that is, the buried oxide layer 2 is placed on the substrate 1, and the polymer layer 3 is placed on the On the buried oxide layer 2 , the optical waveguide layer 4 is placed on the polymer layer 3 . 】

[0067] Arrange the metal signal electrode 6 and the metal ground electrode 7 on the optical waveguide layer 4, [the metal signal electrode 6 and the metal ground electrode 7 are placed on the optical waveguide layer 4;] the bottom surface of the optical waveguide layer 4 is arranged to form 1*2 beam splitting 8, Mach-Zehnder modulator 9 and 2*1 beam combiner 10, 1*2 beam splitter 8 and 2*1 beam combiner 10 are located on both sides of the Mach-Zehnder modulator 9, and 1*2 beam splitter The two output ends of the device 8 are connected through the two input ends of the Mach-Zehnder modu...

Embodiment 2

[0084] Such as Figure 9 As shown, this embodiment includes a substrate 1, a buried oxide layer 2, a polymer layer 3 and an optical waveguide layer 4 arranged sequentially from bottom to top, [that is, the buried oxide layer 2 is placed on the substrate 1, and the polymer layer 3 is placed on the On the buried oxide layer 2 , the optical waveguide layer 4 is placed on the polymer layer 3 . 】

[0085] The metal signal electrode 6 and the metal ground electrode 7 are arranged in the polymer layer 3 below the optical waveguide layer 4, [the metal signal electrode 6 and the metal ground electrode 7 are placed on the optical waveguide layer 4 below the optical waveguide layer 4 and the polymer between layers;] 4 bottom surfaces on the optical waveguide layer are arranged to form 1*2 beam splitter 8, Mach-Zehnder modulator 9 and 2*1 beam combiner 10, 1*2 beam splitter 8 and 2*1 beam combiner 10 is located on both sides of the Mach-Zehnder modulator 9, and the two output ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com