Method for synthesizing sulfide solid electrolyte

A technology of solid electrolytes and sulfides, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of low ionic conductivity of sulfide solid electrolytes, limitations of sulfide solid electrolytes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

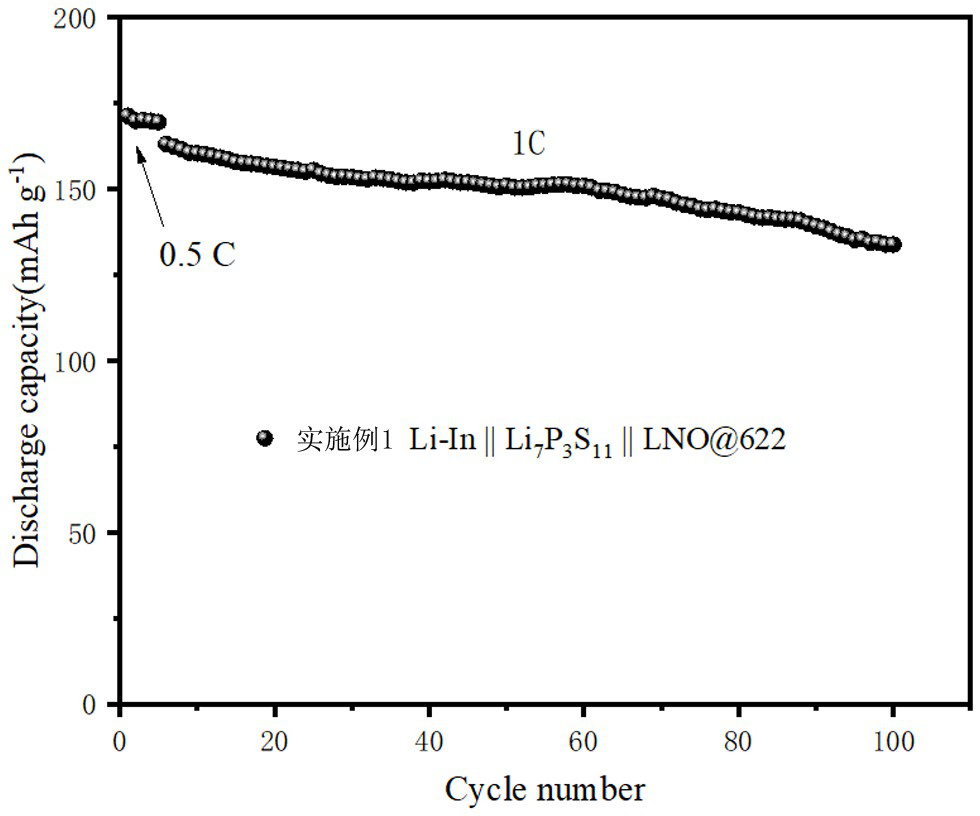

Embodiment 1

[0036] Under a dry argon atmosphere, according to Li 7 P 3 S 11 Composition ratio, weigh 0.8983g of lithium powder, 2.1373g of sulfur powder and 6.1644g of phosphorus pentasulfide to form a mixture with a total mass of 9.2g, of which the excess of sulfur powder is 3%, and place it in a ball mill tank for plasma ball milling for 4h. Under the protection of a dry nitrogen atmosphere, the ball-milled powder was heat-treated at 550°C for 1 hour, and then rapidly cooled to room temperature after heat treatment. The calcined powder was crushed by shearing to obtain Li 7 P 3 S 11 electrolyte. The Li measured by the electrochemical workstation 7 P 3 S 11 The electrolyte has an ionic conductivity of 1.9 mS / cm at 25 °C.

Embodiment 2

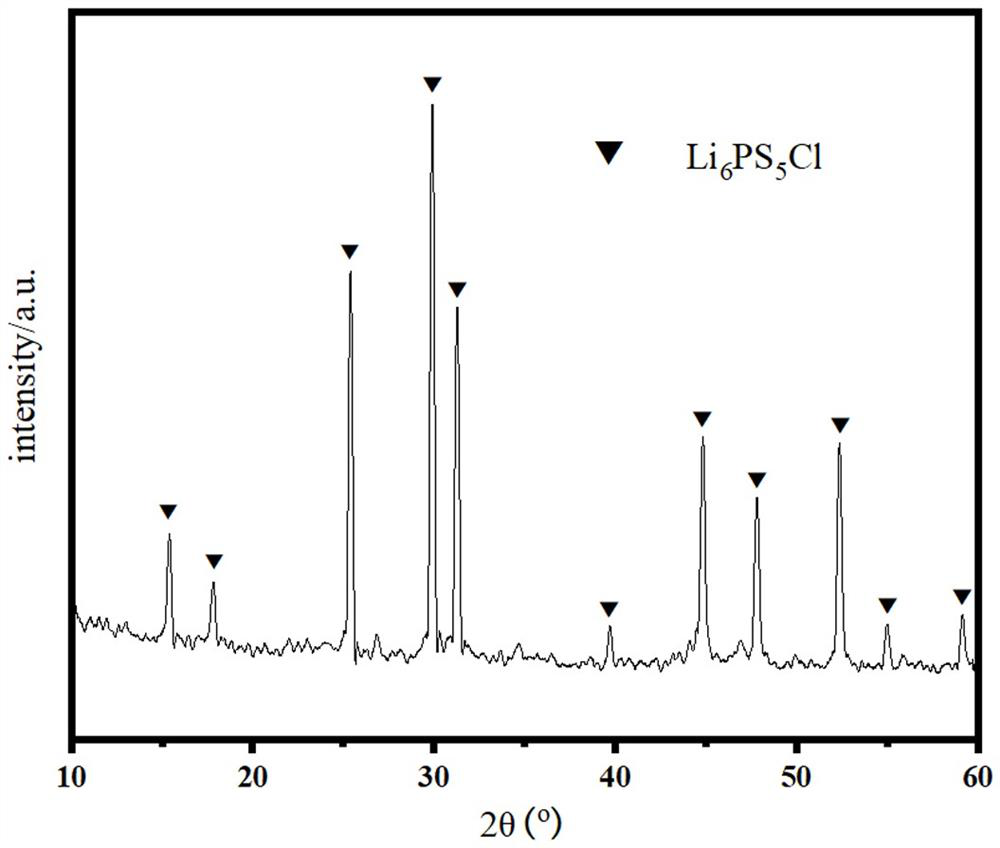

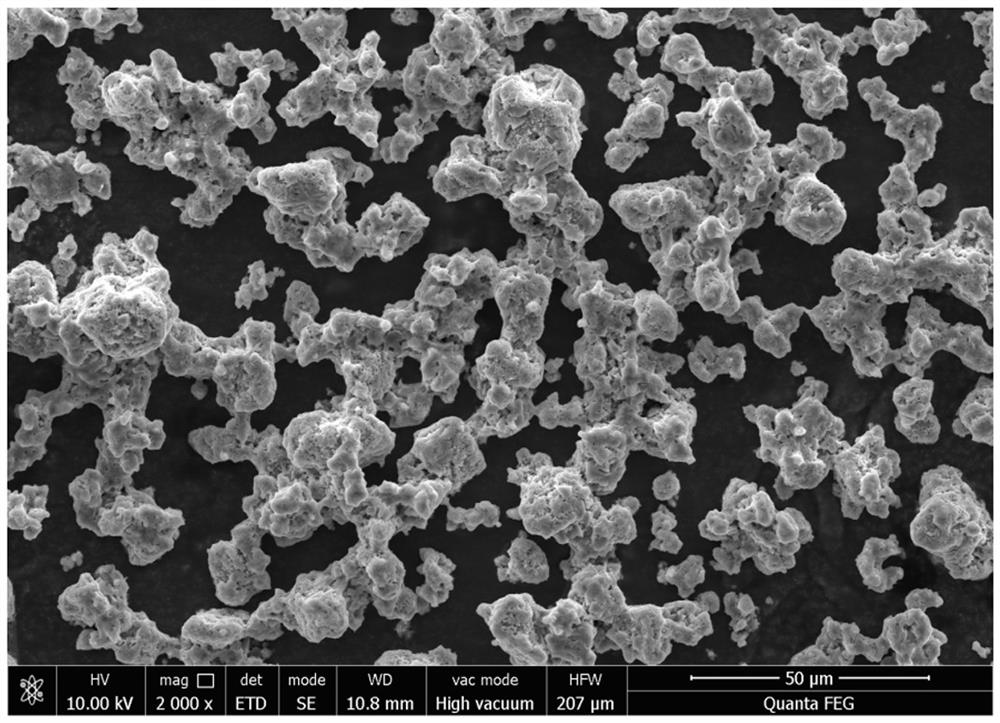

[0038] Under a dry argon atmosphere, according to Li 6 P.S. 5 Cl composition ratio, weigh 1.2358g of lithium powder, 2.9973g of sulfur powder, 3.9574g of phosphorus pentasulfide and 1.5095g of anhydrous lithium chloride to form a mixture with a total mass of 9.7g, place it in a ball mill tank for plasma ball milling for 3h, wherein the excess of sulfur powder is 5 %. Under the protection of a dry nitrogen atmosphere, the ball-milled powder was heat-treated at 450°C for 2 hours, and then rapidly cooled to room temperature after heat treatment. The calcined powder was crushed by shearing to obtain Li 6 P.S. 5 Cl electrolyte. The Li measured by the electrochemical workstation 6 P.S. 5 The ionic conductivity of the Cl electrolyte is 3.2 mS / cm at 25 °C.

Embodiment 3

[0040] Under a dry argon atmosphere, according to Li 9.54 Si 1.74 P 1.44 S 11.7 Cl0.3 Composition ratio, weigh 1.1833g lithium powder, 2.8694g sulfur powder, 2.9601g silicon disulfide, 2.9525g phosphorus pentasulfide and 0.2347g anhydrous lithium chloride to form a mixture with a total mass of 10.2g, place it in a ball mill tank for plasma ball milling for 3h, Among them, the excess of sulfur powder is 3%. Under the protection of a dry argon atmosphere, the ball-milled powder was heat-treated at 550°C for 1 hour, and then rapidly cooled to room temperature after heat treatment. The calcined powder is crushed by grinding to obtain Li 9.54 Si 1.74 P 1.44 S 11.7 Cl 0.3 electrolyte. The Li measured by the electrochemical workstation 9.54 Si 1.74 P 1.44 S 11.7 Cl 0.3 The ionic conductivity of the electrolyte is 3.0 mS / cm at 25 °C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com