Metallocene compound and application

A metallocene compound and catalyst technology, applied in metallocene compounds and application fields, can solve the problem of low molecular weight of polymers, and achieve the effects of high catalytic activity, good high temperature tolerance, and improved insertion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

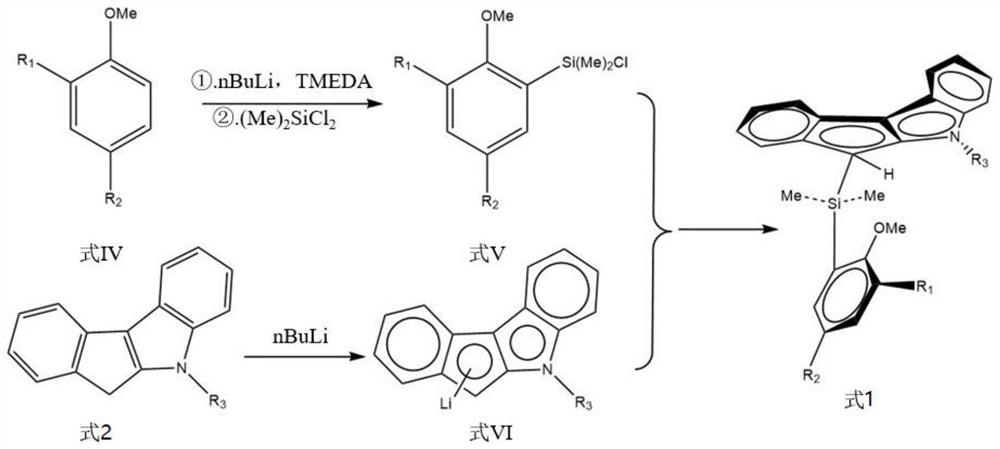

[0065] The present invention has no special limitation on the preparation method of the metallocene compound, and can be synthesized and prepared by using a compound preparation method well known to those skilled in the art; in the present invention, the preparation method of the metallocene compound preferably includes:

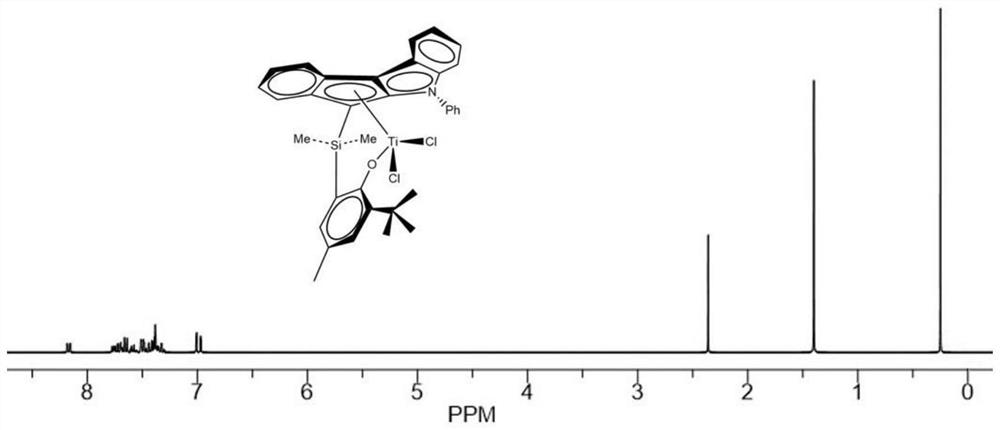

[0066] The compound of formula 1 structure, n-butyllithium, MX 4 React with triethylamine, obtain the metallocene compound of formula I structure;

[0067]

[0068] In the present invention, R in the formula 1 1 , R 2 and R 3 with the above technical scheme described R 1 , R 2 and R 3 Consistent; MX 4 M and X in are consistent with M and X described in the above-mentioned technical solution.

[0069] In the present invention, the compound of formula 1 is preferably according to image 3 The synthetic route shown is prepared; the preparation method of the compound of formula 1 structure preferably comprises:

[0070] reacting the compound of formu...

Embodiment 1~11

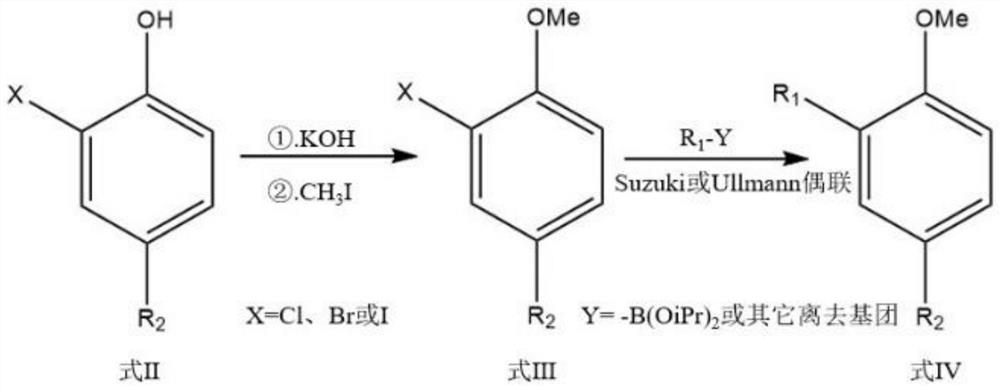

[0102] according to figure 2 The shown route diagram prepares the formula IV structure compound, R in the formula II 2 For methyl or tert-butyl:

[0103] (1)R 1=Phenyl, 1-naphthyl, 9-anthracenyl are prepared according to the following method:

[0104] At room temperature, take 100 mmol of the compound of formula II (commercially available) and dissolve it in 400 mL of dry acetonitrile, replace the system with a nitrogen atmosphere, add KOH (120 mmol) as a solid, stir for 4 h, and then add 150 mmol of methyl iodide (CH 3 1), continue to react for 8h, stop the reaction, filter, remove acetonitrile by rotary evaporation, add 100mL ether and 150mL water, separate and retain the organic phase, then extract the aqueous phase with ether for 3 times, combine and retain the organic phase, dry over anhydrous magnesium sulfate, Filtration, rotary evaporation to remove the solvent, and substantially equivalent to obtain the compound of formula III structure;

[0105] Under a nitroge...

Embodiment 1

[0122] Example 1: R 1 = methyl, R 2 = methyl, R 3 = phenyl;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com