Low-temperature two-component polyurethane material used in field of coal and rock mass reinforcement and preparation method of low-temperature two-component polyurethane material

A two-component polyurethane, low-temperature technology, applied in the field of low-temperature two-component polyurethane materials and their preparation, can solve the problems of potential safety hazards and high reaction heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

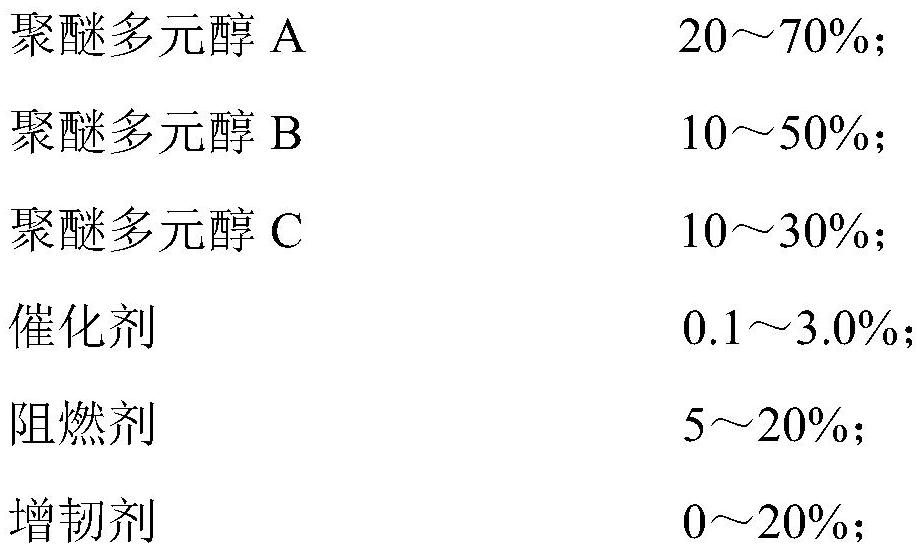

Method used

Image

Examples

Embodiment 1

[0034] To make 100 kilograms of component A of the combined polyether product, put 37.1 kilograms of weighed polyether polyol A, 28.9 kilograms of polyether polyol B, and 16.5 kilograms of polyether polyol C into the reactor for stirring, add N, 0.2 kg of N-dimethylcyclohexylamine, 0.4 kg of N,N-dimethylbenzylamine, 0.4 kg of bismuth isooctanoate, 12.4 kg of tris(2-chloropropyl) phosphate, 4.1 kg of dioctyl phthalate kg, stirred for 45 minutes, sampled and tested, and packaged after passing the test.

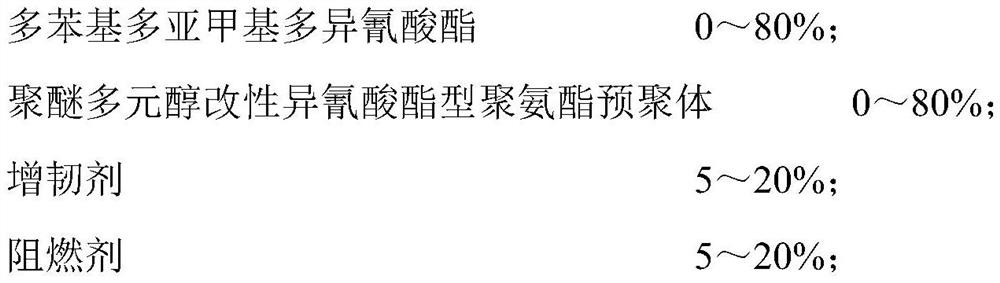

[0035] Make 100 kg of component B of the combined polyether product, 80 kg of polyphenyl polymethylene polyisocyanate, 15 kg of tris(2-chloropropyl) phosphate, and 5 kg of dioctyl phthalate into the reactor Stir in the medium for 45 minutes, take samples for inspection, and pack after passing the test.

[0036] Wherein, the polyether polyol A is a polypropylene oxide ether polyol with an average functionality of 5.7 and a hydroxyl value of 200; the polyether polyol B is a polyp...

Embodiment 2

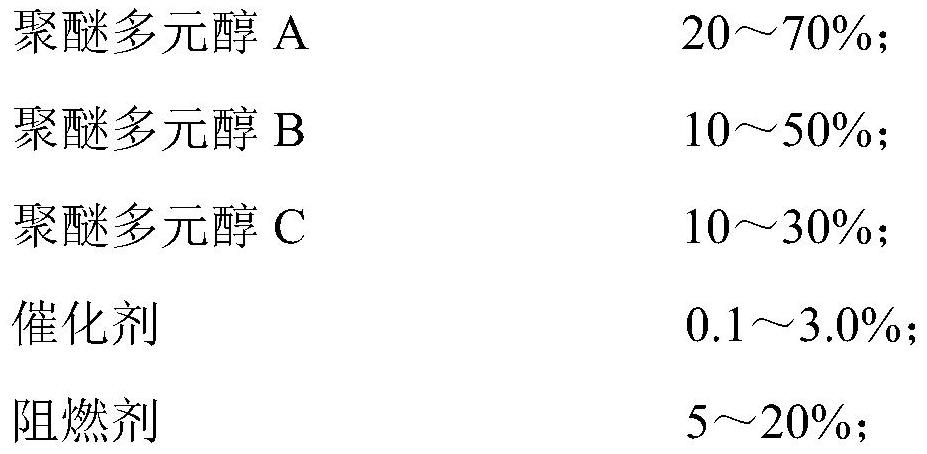

[0042] To make 100 kilograms of component A of the combined polyether product, put 37.1 kilograms of weighed polyether polyol A, 28.9 kilograms of polyether polyol B, and 16.5 kilograms of polyether polyol C into the reactor for stirring, add N, 0.2 kg of N-dimethylcyclohexylamine, 0.4 kg of N,N-dimethylbenzylamine, 0.4 kg of bismuth isooctanoate, 16.5 kg of tris(2-chloropropyl) phosphate, stirred for 45 minutes, sampled and tested, qualified After packing.

[0043] Make 100 kilograms of component B of the combined polyether product, 30 kilograms of polyphenyl polymethylene polyisocyanates, 50 kilograms of polyether polyol modified polyisocyanate type prepolymers, and 10 kilograms of tris (2-chloropropyl) phosphate kg, 10 kg of dioctyl phthalate was put into the reactor and stirred for 45 minutes, sampled and tested, and packaged after passing the test.

[0044] Wherein, the polyether polyol A is a polypropylene oxide ether polyol with an average functionality of 5.3 and a hy...

Embodiment 3

[0050]To make 100 kg of component A of the combined polyether product, put 30.1 kg of polyether polyol A, 23.0 kg of polyether polyol B, and 29.4 kg of polyether polyol C into the reactor and stir, add N, N - 0.2 kg of dimethylcyclohexylamine, 0.4 kg of N,N-dimethylbenzylamine, 0.4 kg of bismuth isooctanoate, 16.5 kg of tris (2-chloropropyl) phosphate, stirred for 45 minutes, sampling test, after passing Package.

[0051] Make 100 kilograms of component B of the combined polyether product, pack 80 kilograms of polyether polyol modified isocyanate prepolymer, 15 kilograms of tris(2-chloropropyl) phosphate, and 5 kilograms of dioctyl phthalate Stir in the reaction kettle for 45 minutes, take a sample for inspection, and pack it after passing the test.

[0052] Wherein, the polyether polyol A is a polypropylene oxide ether polyol with an average functionality of 5.9 and a hydroxyl value of 190; the polyether polyol B is a polypropylene oxide polyol with an average functionality ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com