Polymer microparticle and preparation method thereof

A polymer and microparticle technology, applied in the field of polymer microparticles and its preparation, can solve the problems of difficult size control, poor material scalability, and low production efficiency, so as to achieve simple and easy control of the process, increase the reuse rate, and produce high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

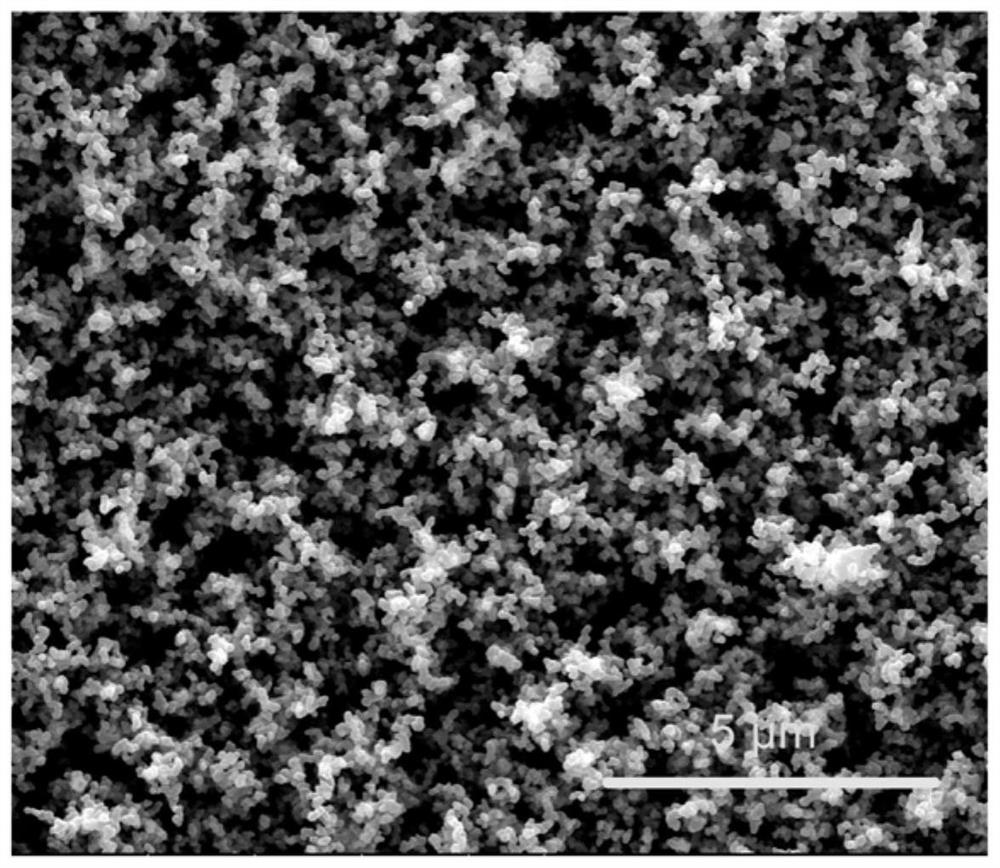

Image

Examples

Embodiment 1

[0038] A kind of polymer particle, its preparation method comprises the following steps:

[0039] (1) prepare super-amphiphobic coating on glass surface by candle soot template method; The specific steps of preparing super-amphiphobic coating include:

[0040] (1.1) Hold and move the glass slide substrate (30mm*30mm*0.17mm) in the flame of a burning candle for 2 minutes to form a uniform layer of black candle smoke, and then transfer it to a desiccator where the Vacuumize the open container with 4mL tetraethoxysilane solution and 4mL ammonia solution respectively, and carry out chemical vapor deposition for 24h to obtain silicon dioxide particles;

[0041] (1.2) The silica particles obtained in step (1.1) were calcined at 550° C. for 3 h, and then perfluorinated with 200 μL of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane chemical vapor deposition for 2 h to obtain Super amphiphobic coating;

[0042] (2) Add 3.5g of polyoxyethylene powder (molecular weight: 5 million) into...

Embodiment 2

[0047] A kind of polymer particle, its preparation method comprises the following steps:

[0048] (1) prepare super-amphiphobic coating on glass surface by candle soot template method; The specific steps of preparing super-amphiphobic coating include:

[0049] (1.1) Hold and move the glass slide substrate (30mm*30mm*0.17mm) in the flame of a burning candle for 2 minutes to form a uniform layer of black candle smoke, and then transfer it to a desiccator where the Vacuumize the open container with 4mL tetraethoxysilane solution and 4mL ammonia solution respectively, and carry out chemical vapor deposition for 24h to obtain silicon dioxide particles;

[0050] (1.2) The silica particles obtained in step (1.1) were calcined at 550° C. for 3 h, and then perfluorinated with 200 μL of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane chemical vapor deposition for 2 h to obtain Super amphiphobic coating;

[0051] (2) Add 3g of polyoxyethylene powder (molecular weight: 5 million) into 9...

Embodiment 3

[0056] A kind of polymer particle, its preparation method comprises the following steps:

[0057] (1) prepare super-amphiphobic coating on glass surface by candle soot template method; The specific steps of preparing super-amphiphobic coating include:

[0058] (1.1) Hold and move the glass slide substrate (30mm*30mm*0.17mm) in the flame of a burning candle for 2 minutes to form a uniform layer of black candle smoke, and then transfer it to a desiccator where the Vacuumize the open container with 4mL tetraethoxysilane solution and 4mL ammonia solution respectively, and carry out chemical vapor deposition for 24h to obtain silicon dioxide particles;

[0059] (1.2) The silica particles obtained in step (1.1) were calcined at 550° C. for 3 h, and then perfluorinated with 200 μL of trichloro(1H, 1H, 2H, 2H perfluorooctyl) silane chemical vapor deposition for 2 h to obtain Super amphiphobic coating;

[0060] (2) Add 2.5g of polyoxyethylene powder (molecular weight: 5 million) into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com