Structural color film with structural stability and high saturation and application thereof

A technology of structural color and polymer film, applied in the direction of coating, etc., can solve the problems of reducing the color saturation of photonic crystal structure and light structure color saturation, and achieve the advantages of short production cycle, low cost, simple and environmentally friendly preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a composite structural color film composed of a single-layer bead array and a polymer film. The specific method is as follows:

[0033] Step (1) A plastic petri dish (10 cm × 10 cm in size) was selected as the substrate for film preparation, and was ultrasonically cleaned with ethanol and deionized water for 10 min, and dried under nitrogen gas for later use.

[0034] Step (2) Mix the PDMS precursor and curing agent (Dow Corning 184) at a mass ratio of 10:1, then add an appropriate amount of carbon black and stir evenly; then pour it into a plastic petri dish and let it level off, under vacuum conditions Remove air bubbles; finally put it in an oven at 80oC for 2 hours to obtain a black PDMS film.

[0035] Step (3) Put the PDMS membrane in step (2) into a low-temperature plasma treatment instrument for hydrophilization treatment (contact angle>150o), to obtain a hydrophilic PDMS membrane.

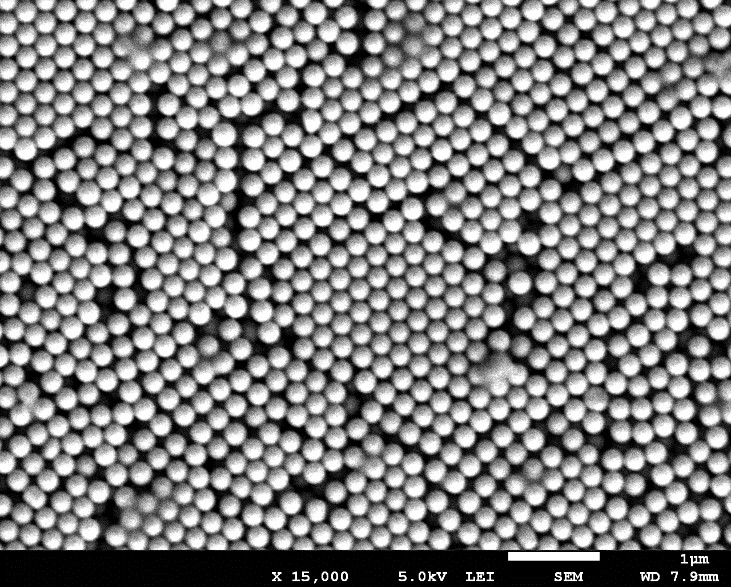

[0036] Step (4) Dilute the 600...

Embodiment 2

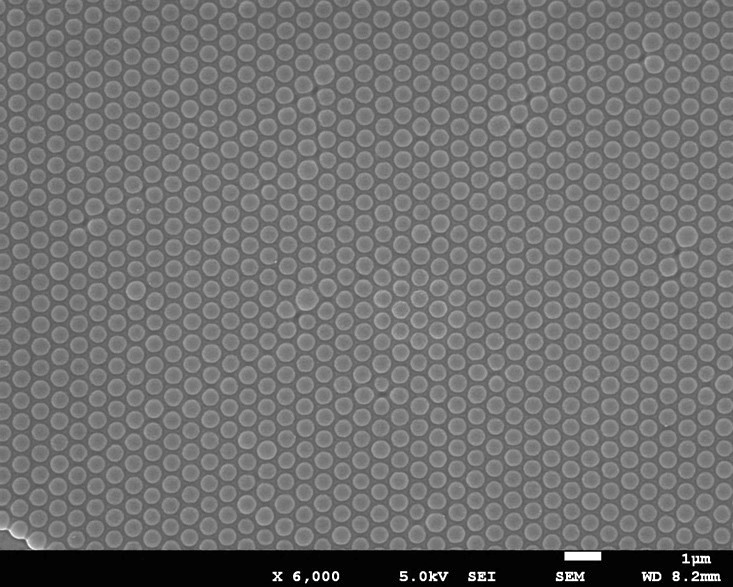

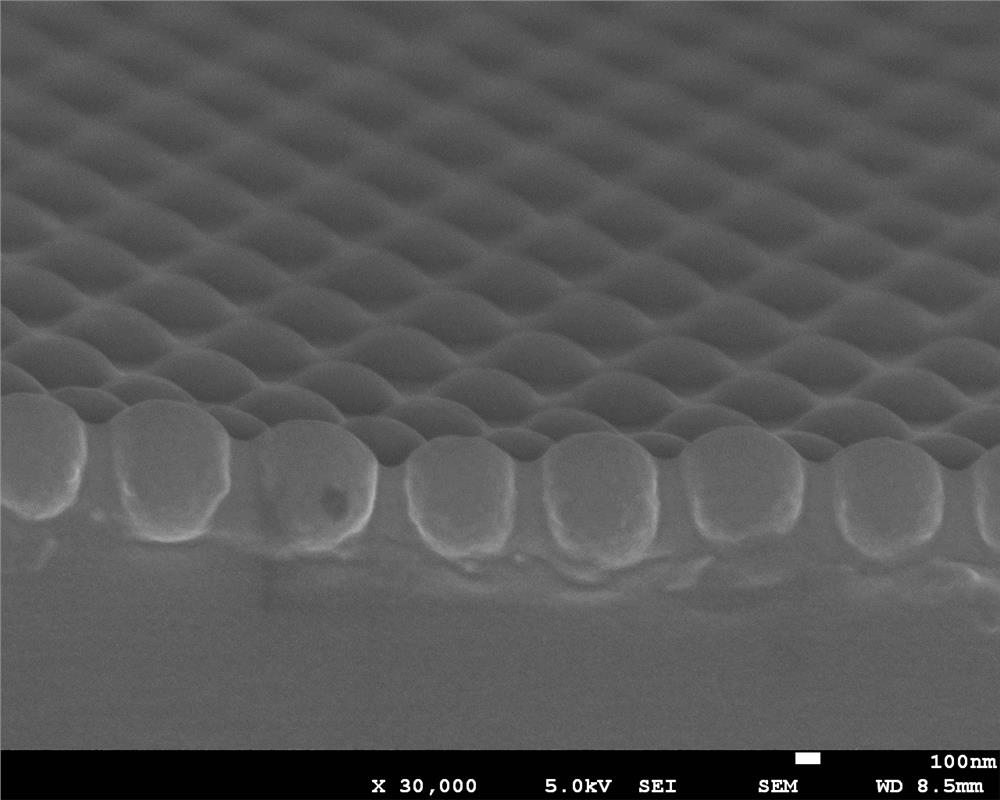

[0039] This embodiment provides a method for preparing a composite structural color film composed of a three-dimensional photonic crystal film and a polymer film. The specific method is as follows:

[0040] Step (1) A plastic petri dish (10 cm × 10 cm in size) was selected as the substrate for film preparation, and was ultrasonically cleaned with ethanol and deionized water for 10 min, and dried under nitrogen gas for later use.

[0041]Step (2) Mix the PDMS precursor and curing agent (Dow Corning 184) at a mass ratio of 10:1, then add an appropriate amount of carbon black and stir evenly; then pour it into a plastic petri dish and let it level off, under vacuum conditions Remove air bubbles; finally put in 80 o C oven cured for 2 h to obtain a black PDMS film.

[0042] Step (3) Put the PDMS membrane in step (2) into a low-temperature plasma treatment instrument for hydrophilization treatment (contact angle>150 o ), to obtain a hydrophilic PDMS membrane.

[0043] Step (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com