Thermocuring peelable blue gel and preparation method thereof

A technology of thermal curing and blue glue, applied in the direction of coating, epoxy resin coating, etc., can solve the problems of residual glue on the glass surface, poor CNC resistance, poor peeling property, etc., and achieve smooth and smooth film surface, high peeling strength, Good effect of CNC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

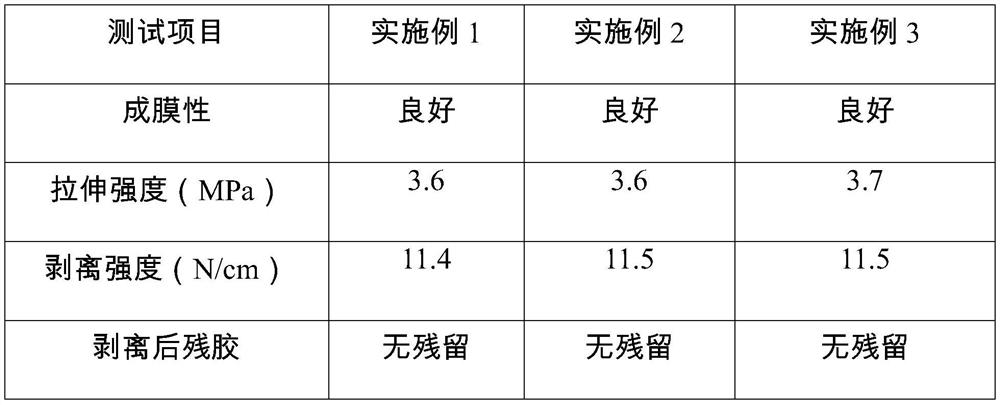

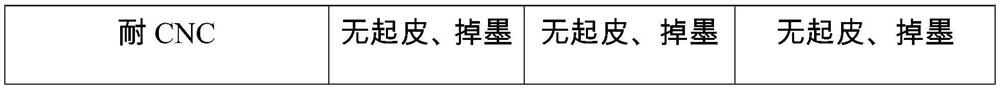

Examples

Embodiment 1

[0037] The present embodiment provides a heat-cured peelable blue glue, which is made up of the following raw materials in parts by weight: 5 parts of UA33, 10 parts of P70, 5 parts of EXT, 0.1 part of DER330-El, 20 parts of TOTM, 1 part parts of D-1050, 0.05 parts of epoxidized soybean oil, 0.01 parts of 2-methylimidazole, 10 parts of DBE, and 0.1 parts of ultramarine blue.

[0038] The preparation method of the above heat-cured peelable blue glue comprises the following steps: (1) Weighing the raw materials according to parts by weight; (2) Mixing the above-mentioned raw materials, stirring and dispersing evenly, grinding to a fineness of less than 50um, and filtering to obtain the heat-cured Peelable blue glue.

Embodiment 2

[0040] The present embodiment provides a heat-cured peelable blue glue, which is composed of the following raw materials in parts by weight: 20 parts of UA33, 50 parts of P70, 30 parts of EXT, 2 parts of DER330-El, 30 parts of TOTM, 20 parts Parts of D~1050, 0.1 parts of epoxidized soybean oil, 0.1 parts of 2-ethylimidazole, 70 parts of DBE, 0.2 parts of cobalt blue.

[0041] The preparation method of the above heat-cured peelable blue glue comprises the following steps: (1) Weighing the raw materials according to parts by weight; (2) Mixing the above-mentioned raw materials, stirring and dispersing evenly, grinding to a fineness of less than 50um, and filtering to obtain the heat-cured Peelable blue glue.

Embodiment 3

[0043] This embodiment provides a heat-cured peelable blue glue, which is composed of the following raw materials in parts by weight: 10 parts of UA33, 50 parts of P70, 12 parts of EXT, 0.5 parts of DER331, 26 parts of TOTM, 12 parts of D-1050, 0.05 parts of epoxidized soybean oil, 0.05 parts of diethylenetriamine, 30 parts of DBE, 0.2 parts of phthalocyanine blue.

[0044] The preparation method of the above heat-cured peelable blue glue comprises the following steps: (1) Weighing the raw materials according to parts by weight; (2) Mixing the above-mentioned raw materials, stirring and dispersing evenly, grinding to a fineness of less than 50um, and filtering to obtain the heat-cured Peelable blue glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com