Soil pollution remediation reagent

A remediation reagent and soil pollution technology, applied in the field of mine soil remediation materials, can solve the problems of unsatisfactory soil remediation effect, easy to leave secondary pollution, long remediation cycle, etc. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

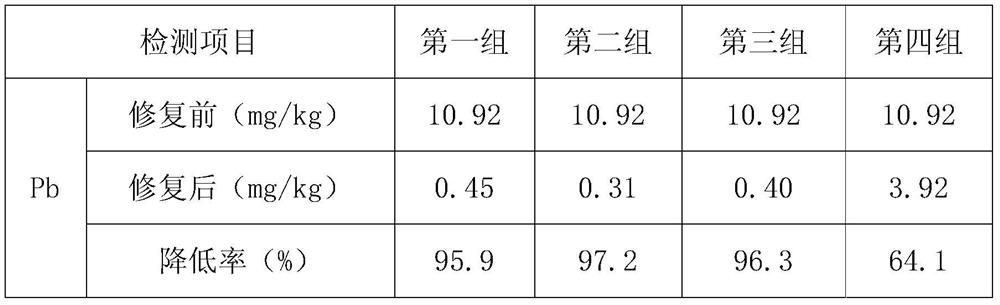

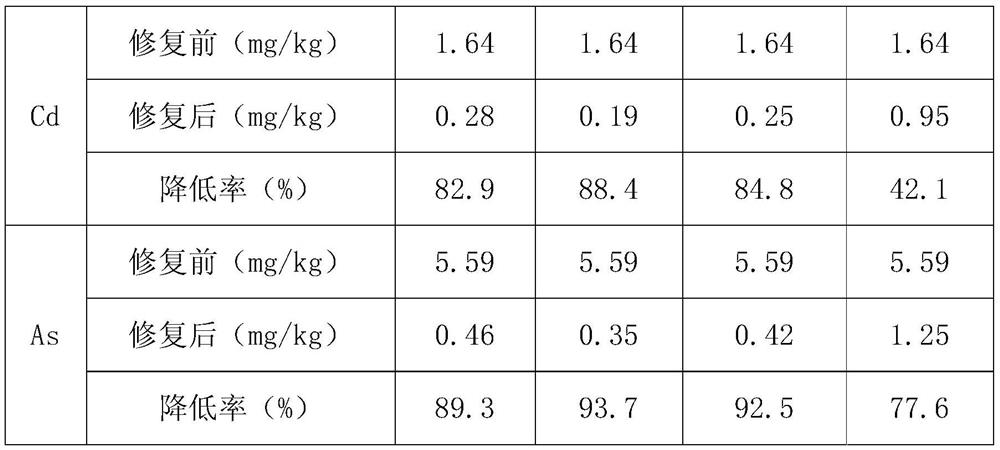

Examples

Embodiment 1

[0019] A soil pollution remediation reagent proposed by the present invention comprises the following raw materials in parts by weight: 40 parts of polyacrylamide, 20 parts of modified diatomite, 18 parts of quicklime, 4 parts of sodium humate, potassium ethyl dithiocarbonate 6 parts, 8 parts of disodium edetate, 0.48 parts of water retaining agent;

[0020] Wherein, the modified diatomite is prepared by the following method: Weigh diatomite, cyclodextrin, epoxy linseed oil and o-phenanthroline respectively according to the mass ratio of 20:1:3:0.2, and the specific gravity Diatomaceous earth, epoxy linseed oil and o-phenanthroline were mixed, and ethanol with 6 times the mass of diatomite was added, mixed and stirred at 60°C for 20min, cooled to room temperature, added cyclodextrin of the specific gravity, and continued to stir After 30 minutes, concentrate under reduced pressure, dry in vacuum at 50°C for 2 hours, and cool to room temperature to obtain modified diatomite;

...

Embodiment 2

[0024] A soil pollution remediation reagent proposed by the present invention comprises the following raw materials in parts by weight: 45 parts of polyacrylamide, 25 parts of modified diatomite, 16 parts of quicklime, 6 parts of sodium humate, potassium ethyl dithiocarbonate 4 parts, 6 parts of disodium edetate, 0.32 parts of water retaining agent;

[0025] Wherein, the modified diatomite is prepared by the following method: Weigh diatomite, cyclodextrin, epoxy linseed oil and o-phenanthroline respectively according to the mass ratio of 23:1:4:0.5, and the specific gravity Diatomaceous earth, epoxy linseed oil and o-phenanthroline were mixed, and ethanol with 5 times the mass of diatomite was added, mixed and stirred at 60°C for 25min, cooled to room temperature, added cyclodextrin of the specific gravity, and continued to stir 30min, then concentrated under reduced pressure, dried in vacuum at 55°C for 1.5h, and cooled to room temperature to obtain modified diatomite;

[00...

Embodiment 3

[0029] A soil pollution remediation reagent proposed by the present invention comprises the following raw materials in parts by weight: 50 parts of polyacrylamide, 30 parts of modified diatomite, 14 parts of quicklime, 8 parts of sodium humate, potassium ethyl dithiocarbonate 3 parts, 4 parts of disodium edetate, 0.26 parts of water retaining agent;

[0030] Wherein, the modified diatomite is prepared by the following method: Weigh diatomite, cyclodextrin, epoxy linseed oil and o-phenanthroline respectively according to the mass ratio of 26:1:6:0.7, and the specific gravity Diatomaceous earth, epoxy linseed oil and o-phenanthroline were mixed, and ethanol with 3 times the mass of diatomite was added, mixed and stirred at 60°C for 30min, cooled to room temperature, added cyclodextrin of the specific gravity, and continued to stir After 30 minutes, concentrate under reduced pressure, dry in vacuum at 55°C for 1 hour, and cool to room temperature to obtain modified diatomite;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com