Liquid adding device, dry towel production device comprising liquid adding device and dry towel production method

A technology of liquid adding device and production device, which is applied in the processing of textile materials, equipment configuration for processing textile materials, liquid/gas/steam textile material processing, etc. It can solve the problems of affecting foam feeling, high processing cost, and polluting the environment. Achieve the effects of reducing production and processing costs, avoiding pollution of the production environment, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

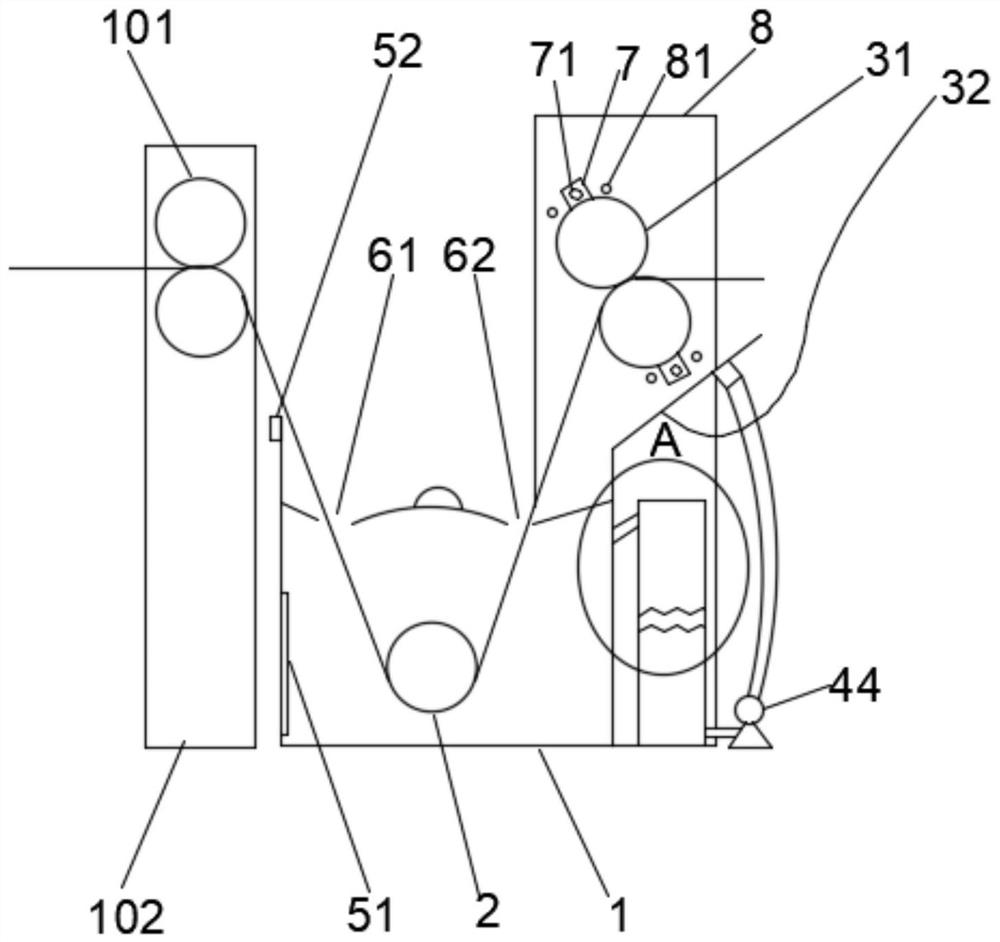

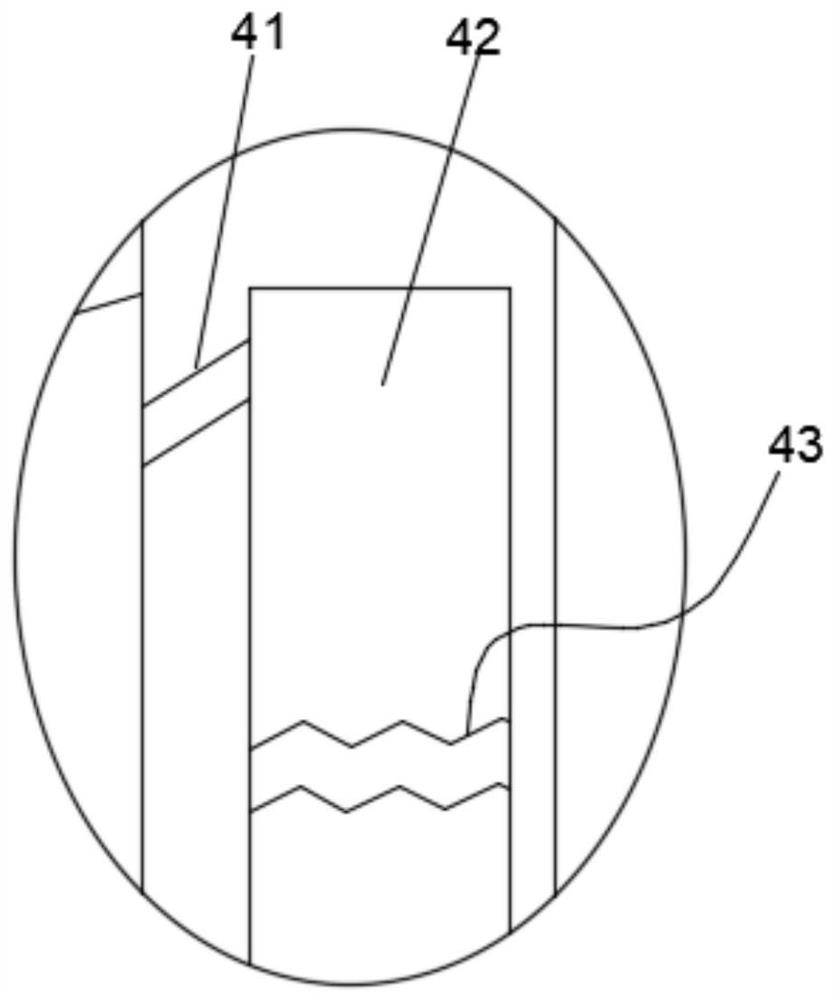

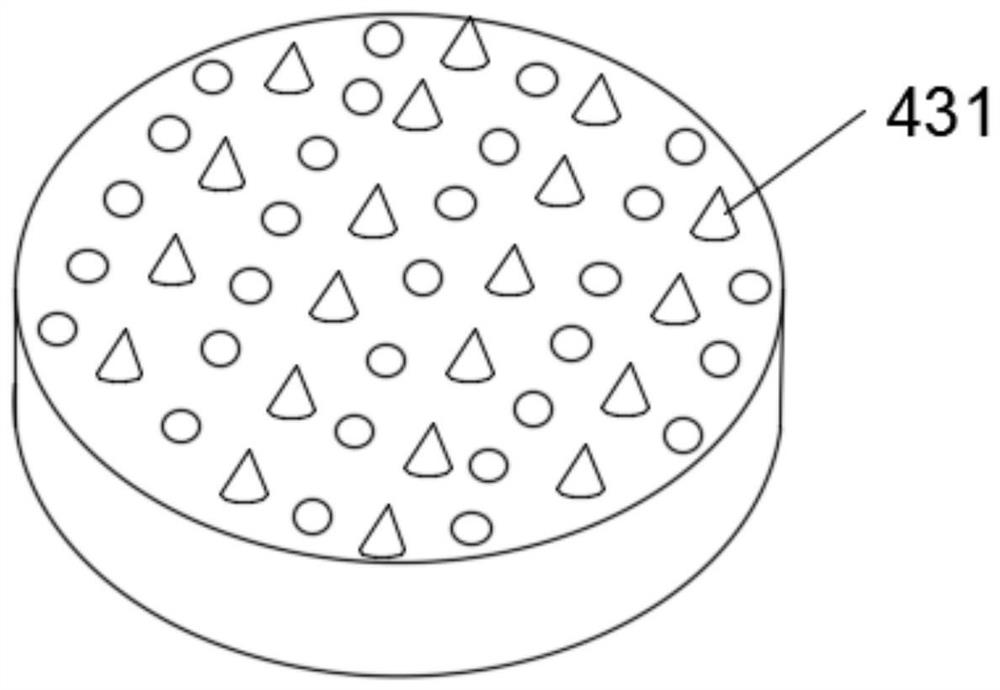

[0026] see figure 1 As shown, the liquid adding device of this embodiment is used to add liquid to the non-woven fabric to make it fully absorb the feed liquid. The liquid adding device listed in this embodiment is used for the preparation of dry wipes. Obviously, the adding liquid of the present invention The application of the liquid device is not limited thereto, and the cloth base materials to which the liquid adding device of the present invention can be applied are not limited to non-woven fabrics, which may also be cotton cloth, linen cloth, silk, blended fabrics and the like. The liquid adding device can make the non-woven fabric absorb the material liquid. It includes a liquid storage tank 1 for accommodating the feed liquid. A traction roller 2 is arranged in the liquid storage tank 1. The central axis of the traction roller 2 is arranged in a direction parallel to the horizontal plane. Preferably, the traction roller 2 is located in the liquid storage tank 1 Below ...

Embodiment 2

[0033] Such as Figure 4 As shown, the dry towel production device of this embodiment is used in combination with a conventional spunlace nonwoven fabric processing production line, and includes the liquid adding device of Embodiment 1. The liquid adding device is arranged on the spunlace production line of the non-woven fabric, and the liquid adding device is connected with the spunlace device 91 and the drying device 92 respectively. A water squeezing part is also provided between the liquid adding device and the spunlace device 91. The water squeezing part includes a second pair of rollers 101 and a recovery liquid tank 102. The second pair of rollers 101 is arranged above the recovery liquid tank 102. After spunlace processing After passing through the second pair of rollers 101 , the obtained nonwoven fabric passes through the drawing roller 2 and is output through the first pair of rollers 31 . Therefore, the water in the nonwoven fabric after the spunlace process can b...

Embodiment 3

[0034] Embodiment three: the preparation of cleansing dry towel:

[0035] First carry out the preparation of feed liquid, the formula of the feed liquid of cleansing dry towel is shown in Table 1 with reference to:

[0036] The formula of feed liquid of table 1 cleansing dry towel

[0037]

[0038]

[0039] The feed liquid of cleansing dry towel is prepared according to the following method:

[0040] 1. Add disodium EDTA, glycerin, ethylhexylglycerin, methylparaben, acrylic acid (ester) / C10-30 alkanol acrylate cross-linked polymer into an appropriate amount of deionized water, and heat to 75-90 degrees under stirring , and then high-speed homogenization, that is, A;

[0041] 2. Weigh the vaseline and heat it in a water bath at 80°C until it is completely melted to obtain B;

[0042] 3. Weigh cocamidopropyl betaine, sodium lauroyl sarcosinate, sodium lauroyl glutamate, lauryl glucoside, decyl glucoside and mix well, then heat to 75-85°C to get C ;

[0043] 4. Pour B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com