Strong coupling solid-liquid multiphase flow numerical simulation method

A numerical simulation and multiphase flow technology, applied in the field of mountain disaster prevention and environmental governance, can solve problems such as inability to analyze multiphase flow in depth, unclear physical mechanism, and oversimplified numerical simulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment discloses a numerical simulation method for strongly coupled solid-liquid multiphase flow, which specifically includes the following steps:

[0054] S1: Determine the force characteristics of the solid and liquid phases through physical and mechanical analysis, and write the force characteristics of the solid and liquid phases into the numerical model;

[0055] In this step, the mechanical characteristics of the solid phase and the liquid phase are determined respectively through physical and mechanical analysis, and all the parameters that need to be prepared in the preprocessing stage of this numerical method are obtained, and the stress tensor, physical force and other stress characteristics are brought into the mathematical form in the numerical model;

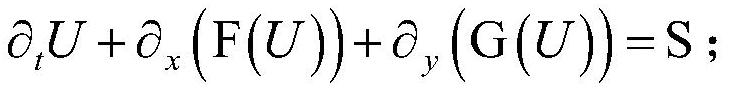

[0056] Preferably, the governing equation of the numerical model is a shallow water wave equation obtained by simplifying the depth integration method based on the incompressible Navier-Stokes equati...

Embodiment 2

[0111] Based on the method in Example 1, relevant experimental operations are carried out in this example, specifically to simulate the movement of complex multiple fluids in the experimental tank. All parameters will be obtained from physical experiments and used to compare the results of numerical experiments and physical time. It is used to reveal the force mode and motion mechanism of complex multiphase flow fluid.

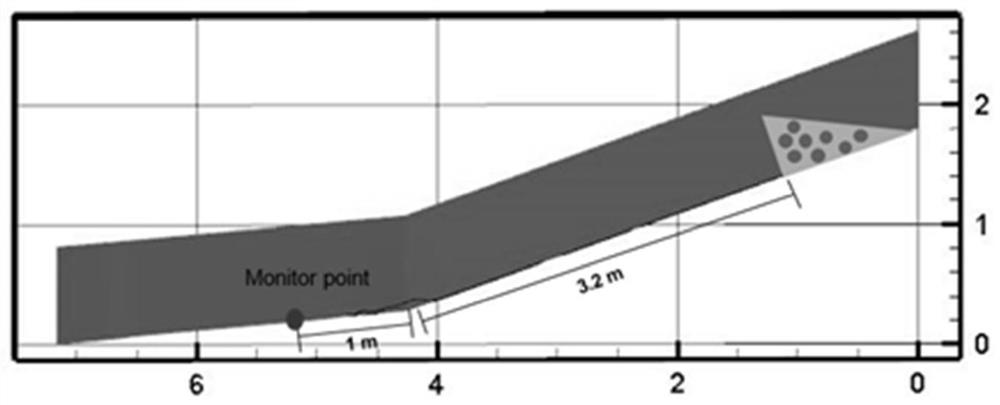

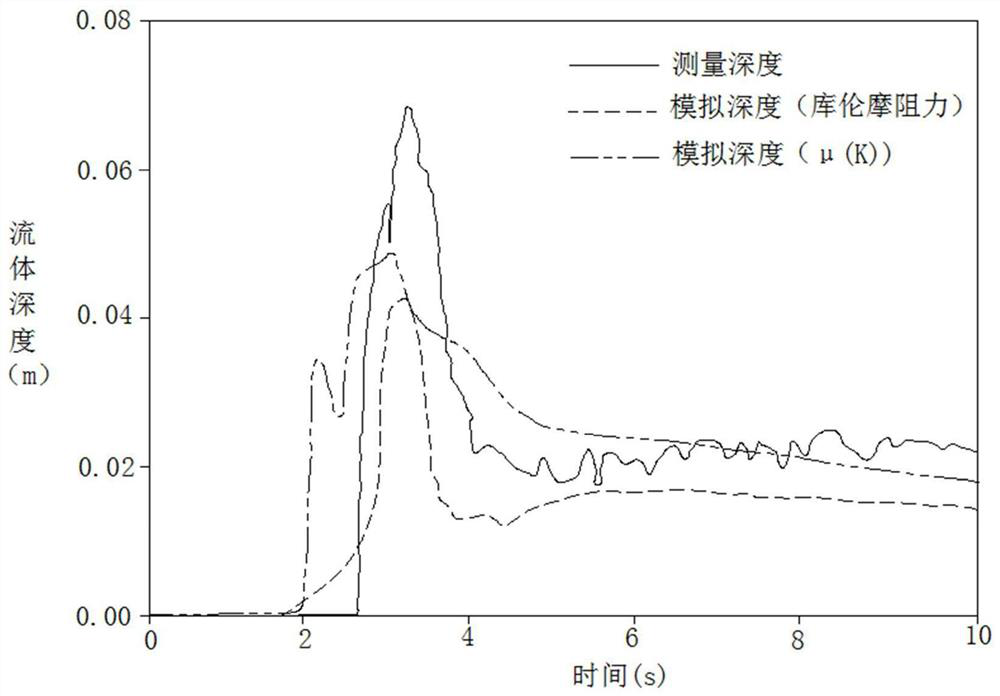

[0112] Specifically, the experimental trough is set so that the toe of the lower section is 5 degrees, and the toe of the upper section is 20 degrees. The volume of each experiment is 0.05 cubic meters, and the maximum bearing volume of the experimental trough is 0.17 cubic meters. figure 1 ; For the properties of solids and fluids, in this embodiment, the solids are used to describe their frictional resistance characteristics, while for the liquid phase, Newtonian fluids are used. For the interaction force, we use the relevant stress model defined by the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com