Integrated device for dust removal, desulfurization and denitrification of ship waste gas and ship

A desulfurization and denitrification, ship technology, applied in the field of ship waste gas dust removal, desulfurization and denitrification treatment, can solve the problems of black smoke from ship exhaust, excessive pollutant discharge, etc., and achieve the effect of reducing the installation and use height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

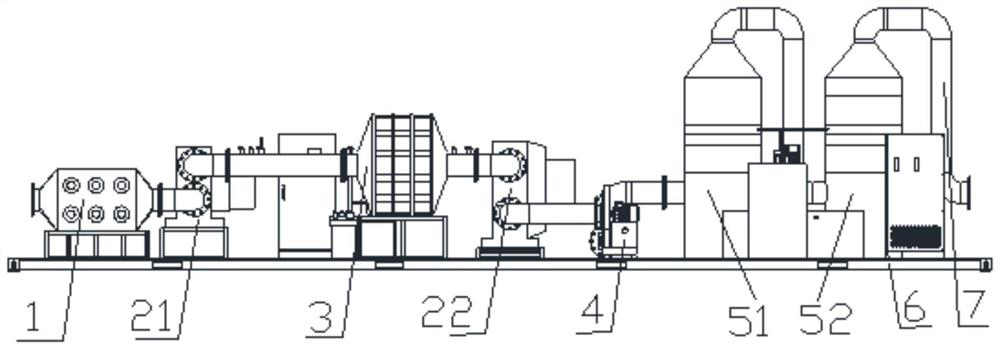

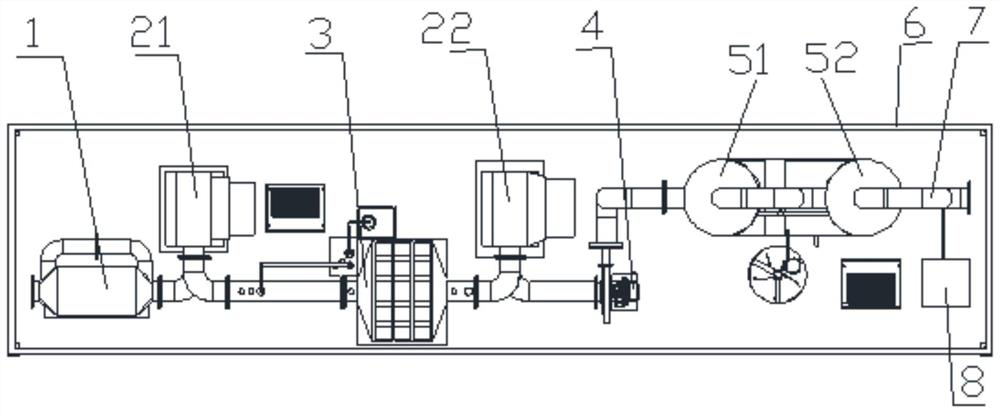

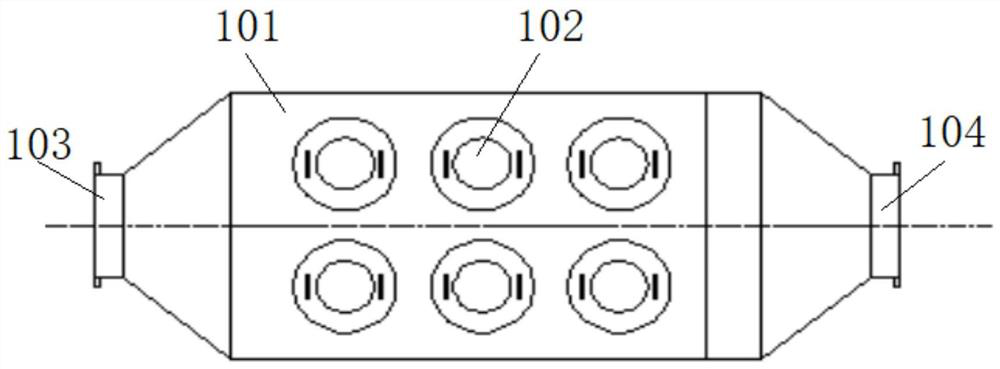

[0042] The integrated device for dust removal, desulfurization and denitrification of ship exhaust gas in this embodiment mainly includes eight units: the metal DPF dust removal unit 1, the air-cooled heat exchanger (including the first air-cooled heat exchanger 21 and the second air-cooled heat exchanger 22 ), SCR denitrification unit 3, induced draft fan 4, wet desulfurization unit (including the first desulfurization tower 51 and the second desulfurization tower 52), container 6, equipment connection pipeline support 7 and exhaust gas online monitoring equipment 8. The outlet of the metal DPF dedusting unit 1 is connected to the inlet of the first air-cooled heat exchanger 21, the outlet of the first air-cooled heat exchanger 21 is connected to the inlet of the SCR denitrification unit 3, the outlet of the SCR denitrification unit 3 is connected to the induced draft fan 4, and the induced draft fan 4 is connected to the The inlet of the second air-cooled heat exchanger 22 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com