High-strength titanium-based boron-tungsten composite shielding material and preparation method thereof

A composite shielding, titanium-based technology, applied in the field of high-strength titanium-based boron-tungsten composite shielding materials and their preparation, can solve the problems of single function, material strength, low service temperature, etc., achieve simple operation process, improve tensile strength performance, Easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

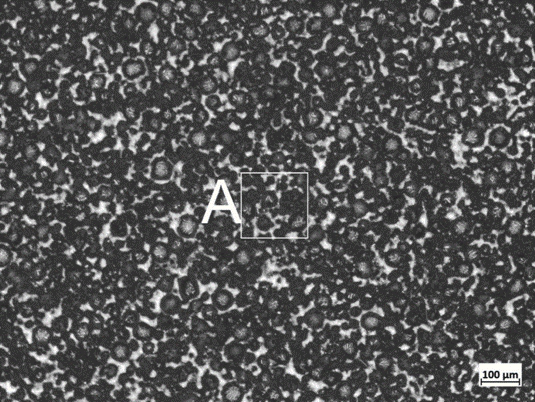

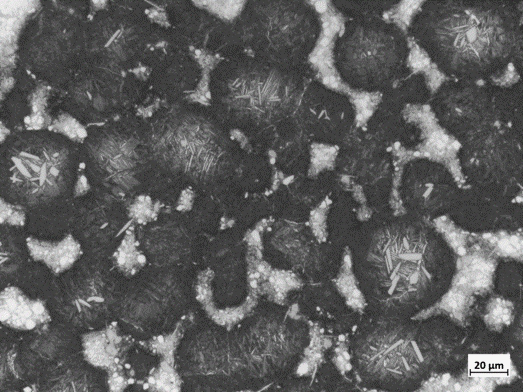

Image

Examples

Embodiment 1

[0032] The high-strength titanium-based boron-tungsten composite shielding material of this embodiment is prepared from the following raw materials in mass percentages: boron 0.79%, tungsten 32.45%, and titanium 66.76%.

[0033] The preparation process of the high-strength titanium-based boron-tungsten composite shielding material in this embodiment includes the following steps:

[0034] Step 1. Prepare boron powder with a mass purity of 99.93% and a particle size of 4 μm, tungsten powder with a mass purity of 99.95% and a particle size of 3 μm, and titanium powder with a mass purity of 99.94% and a particle size of 63 μm. Weigh the boron Powder 1.58g, tungsten powder 64.90g and titanium powder 133.52g, a total of 200g, mixed to obtain a mixed powder; wherein, the volume fraction of each raw material powder in the mixed powder is: boron powder 2%, tungsten powder 10%, titanium powder 88%.

[0035] Step 2, according to the mass ratio of bearing steel ball and mixed powder 5:1, w...

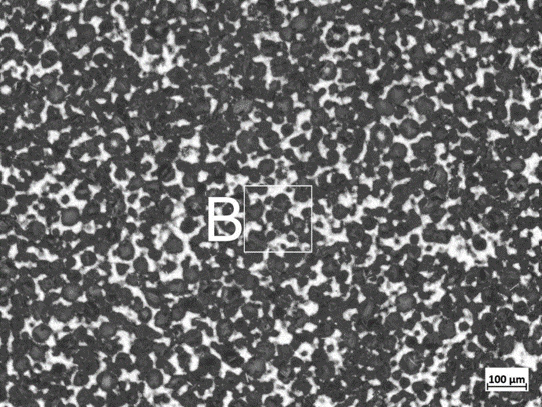

Embodiment 2

[0039] The high-strength titanium-based boron-tungsten composite shielding material of this embodiment is prepared from the following raw materials in mass percentages: 0.84% boron carbide, 32.43% tungsten, and 66.73% titanium.

[0040] The preparation process of the high-strength titanium-based boron-tungsten composite shielding material in this embodiment includes the following steps:

[0041] Step 1. Prepare boron carbide powder with a mass purity of 99.95% and a particle size of 5 μm, tungsten powder with a mass purity of 99.95% and a particle size of 4 μm, and titanium powder with a mass purity of 99.94% and a particle size of 35 μm. Weigh the above 1.68g of boron carbide powder, 64.86g of tungsten powder and 133.46g of titanium powder, 200g in total, mixed well to obtain a mixed powder; wherein, the volume fraction of each raw material powder in the mixed powder is: boron carbide powder 2%, tungsten powder 10% , 88% titanium powder.

[0042] Step 2, according to the m...

Embodiment 3

[0049] The high-strength titanium-based boron-tungsten composite shielding material of this embodiment is prepared from the following raw materials in mass percentages: 0.40% boron, 0.42% boron carbide, 32.44% tungsten, and 66.74% titanium.

[0050] The preparation process of the high-strength titanium-based boron-tungsten composite shielding material in this embodiment includes the following steps:

[0051] Step 1, prepare mass purity as 99.93%, boron powder with a particle size of 3 μm, mass purity of 99.95%, boron carbide powder with a particle size of 5 μm, mass purity of 99.95%, tungsten powder with a particle size of 5 μm, with a mass purity of 99.94%, titanium powder with a particle size of 70 μm, weigh 0.8g of the above-mentioned boron powder, 0.84g of boron carbide powder, 64.88g of tungsten powder and 133.48g of titanium powder, a total of 200g, and mix well to obtain a mixed powder; wherein, each of the mixed powder The volume fraction of raw material powder is: bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com