Passive power factor correction converter with high power factor and low output ripple

A passive power factor, power factor correction technology, applied in the direction of converting DC power input to DC power output, output power conversion device, high-efficiency power electronic conversion, etc., can solve problems such as input and output characteristic limitations, and achieve circuit reliability. High, simple control, small output ripple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

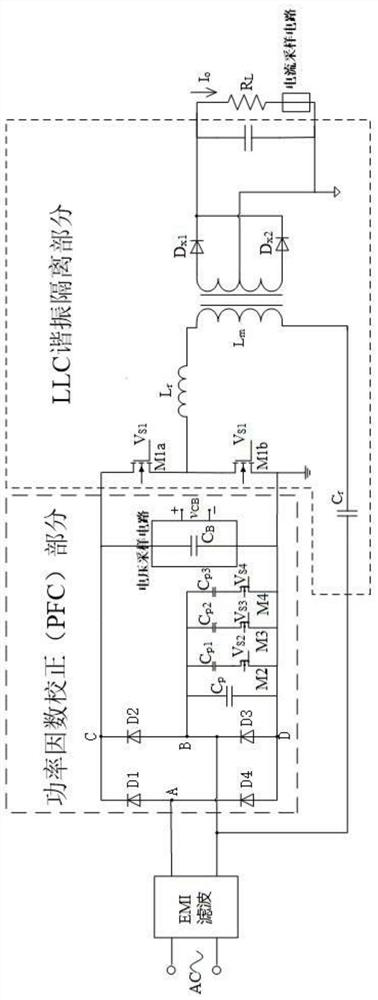

[0036] A passive power factor correction converter with high power factor and low output ripple of the present invention includes a power factor correction PFC part, a resonance isolation LLC part and a control system.

[0037] Power Factor Correction PFC section as figure 1 As shown, including rectifier bridge, charge pump capacitor network and post-stage bus capacitor.

[0038] The power supply system is connected to the rectifier bridge through the EMI filter input, the positive input terminal is connected to the diode node A, that is, the anode of D1 is connected to the cathode of D4, and the negative input terminal is connected to the diode node B, that is, the anode of D2 is connected to the cathode of D3; the positive and negative output nodes of the rectifier bridge are respectively Denoted as node C (D1 cathode and D2 cathode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com