Circuit board with embedded heat dissipation material and manufacturing method thereof

A heat-dissipating material and manufacturing method technology, applied in the direction of printed circuit manufacturing, printed circuit, circuit heating device, etc., can solve the problems of unfavorable long-term reliability of circuit boards, large differences in thermal conductivity, complicated process flow, etc., and achieve improvement of adhesive flow Defects, optimized thermal conductivity, improved life and long-term reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Add large particles with a particle size of 25-30 μm and small particles with a particle size of 3.8-4.7 μm into the resin system to prepare glue; for particles with different particle sizes, ball mills of different specifications or other methods can be used to obtain them.

[0038] The particles of the two particle sizes selected in Example 1 are mixed to form a stacking model A. According to the packing model A, the relationship between the large particle radius R and the small particle radius r can be inversely verified.

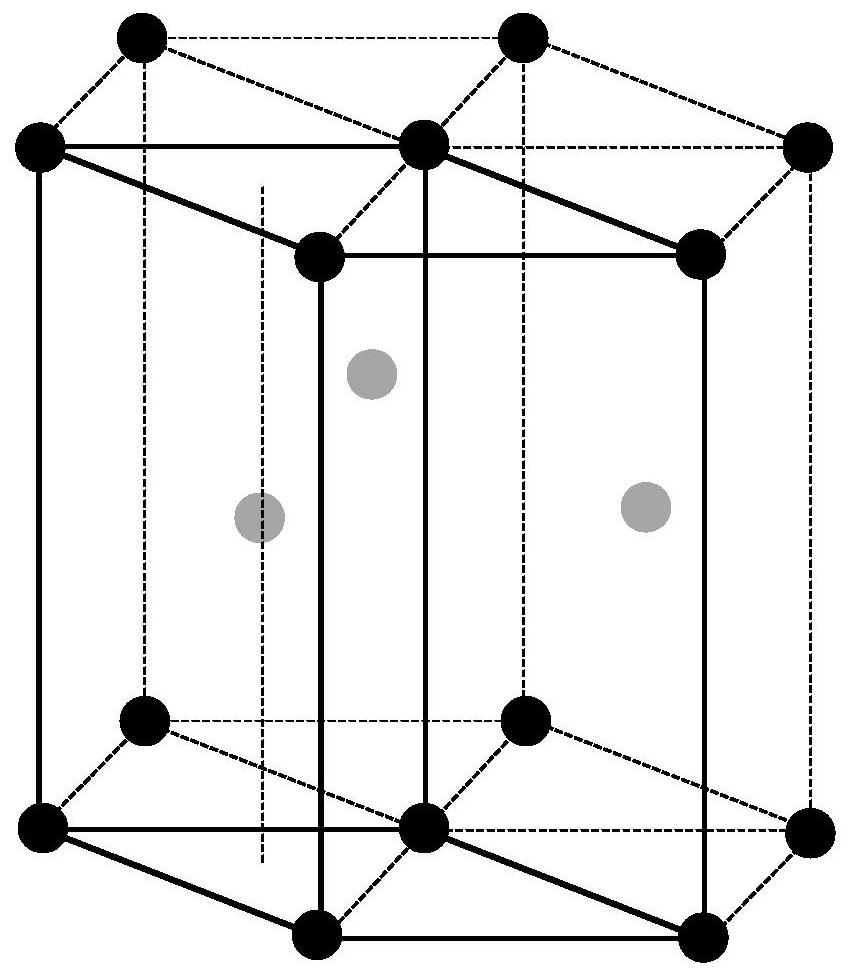

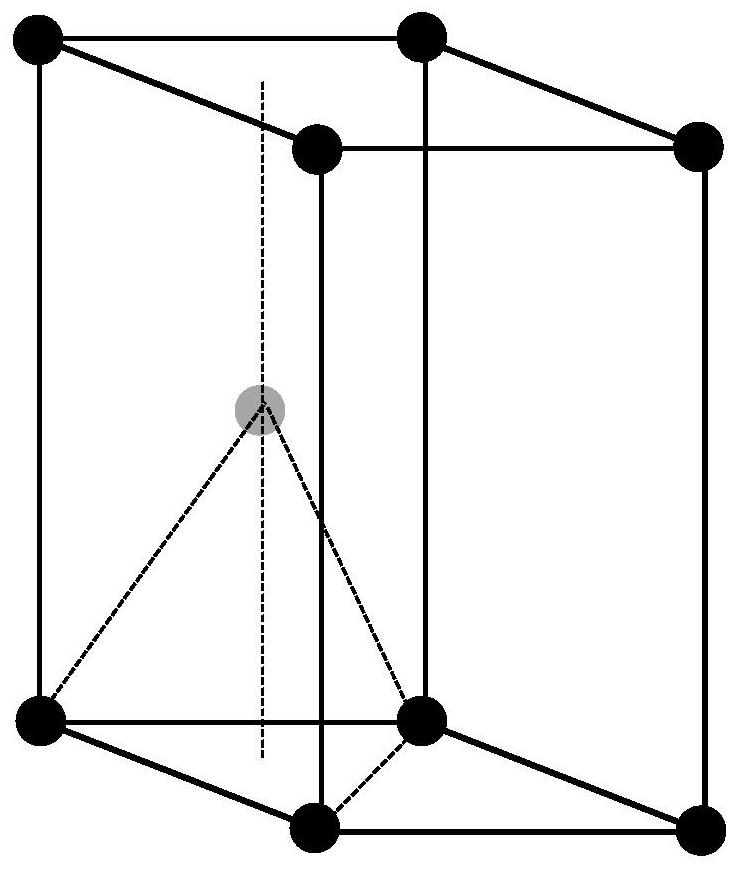

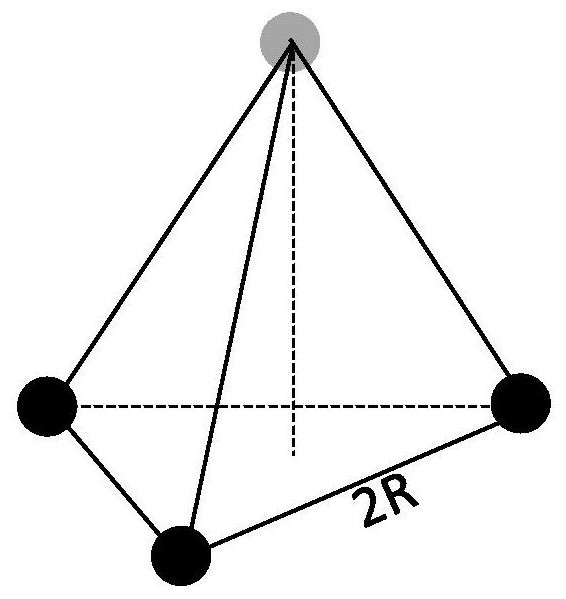

[0039] Stacked model A such as figure 1 The hexagonal closest-packed regular hexahedral cylinder shown, the large particles are located at the twelve vertices of the regular hexahedral cylinder, and there are three small particles in the middle of the regular hexahedral cylinder; figure 2 for figure 1 A tetrahedron separated from , figure 2 A regular tetrahedron unit can be split in the middle, the side length of the bottom triangle of the...

Embodiment 2

[0047] (1) Add large particles with a particle size of 25-30 μm and small particles with a particle size of 15.8-18.9 μm in the adhesive to prepare glue; for particles with different particle sizes, ball mills of different specifications or other methods can be used to obtain them .

[0048] The particles of the two particle sizes selected in Example 2 are mixed to form the packing model B, and the relationship between the large particle radius R and the small particle radius r can be verified by inverse deduction according to the packing model B.

[0049] Stacking model B is Figure 6 In the body-centered cubic packing shown, the large particles are located at the eight vertices of the cube, and the small particles are located at the center of the cube, where, a 2 +b 2 =(4R) 2 ,therefore Stacked Model B's according to Figure 7 , Figure 8 Calculation, It is consistent with the particle size relationship between the large particle size and the small particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com