co@ncnt material prepared by reduction-oxidation-reduction strategy and its preparation method

A strategic, oxidative technology, applied in the field of porous materials, to achieve the effect of good activity and selectivity, enhanced adsorption and dissociation ability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method of preparing a CO @ NCNT material prepared by a reduction-oxidation-reduction strategy, including the following steps:

[0038] (1) Dimethylimidazole (12 mmol) was added to anhydrous methanol (75 mL), and the ultrasound was dissolved, and the organic ligand solution was obtained; CO (NO) 3 ) 2 · 6h 2 O (3 mmol) is dissolved in anhydrous methanol (75 mL) to obtain a Co salt solution;

[0039] (2) The Co salt solution in step (1) is added to the organic ligand solution, stirred at room temperature for 15 min, and then filtered the resulting solution after 24 h, and washed three times, dried three times at 60 ° C to obtain ZIF-67 materials at 60 ° C. ;

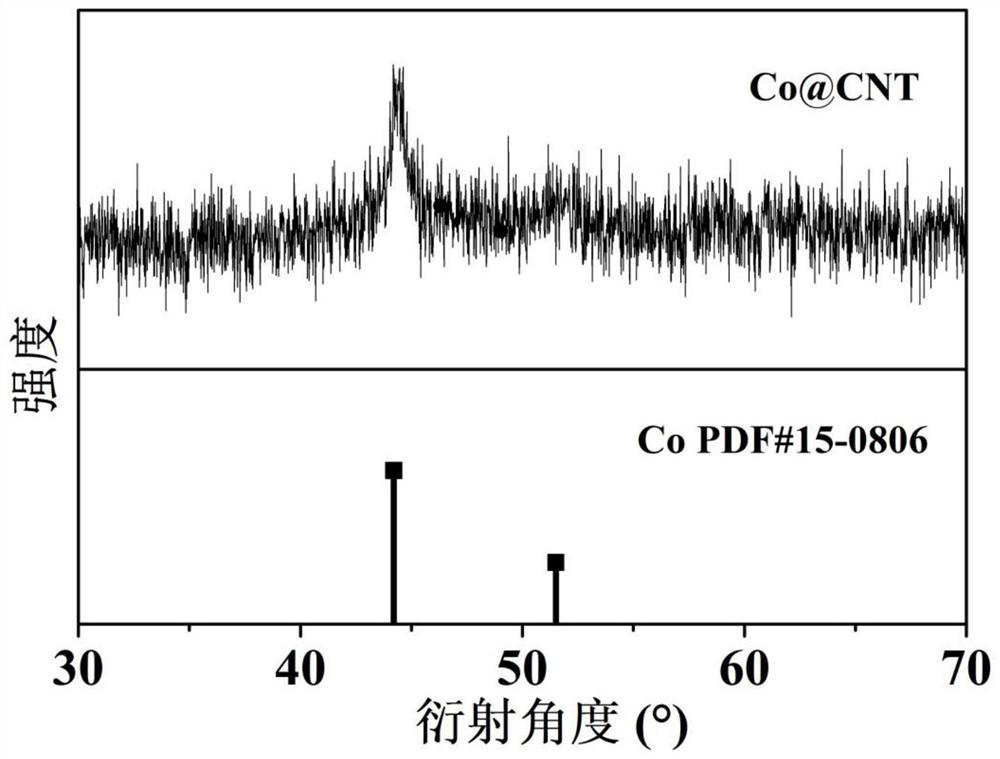

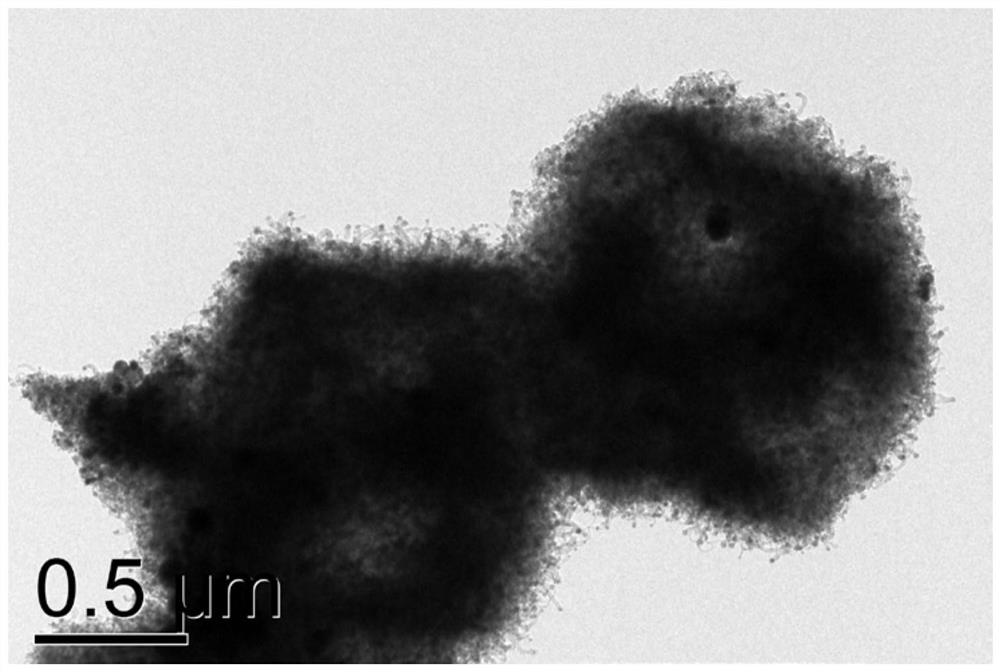

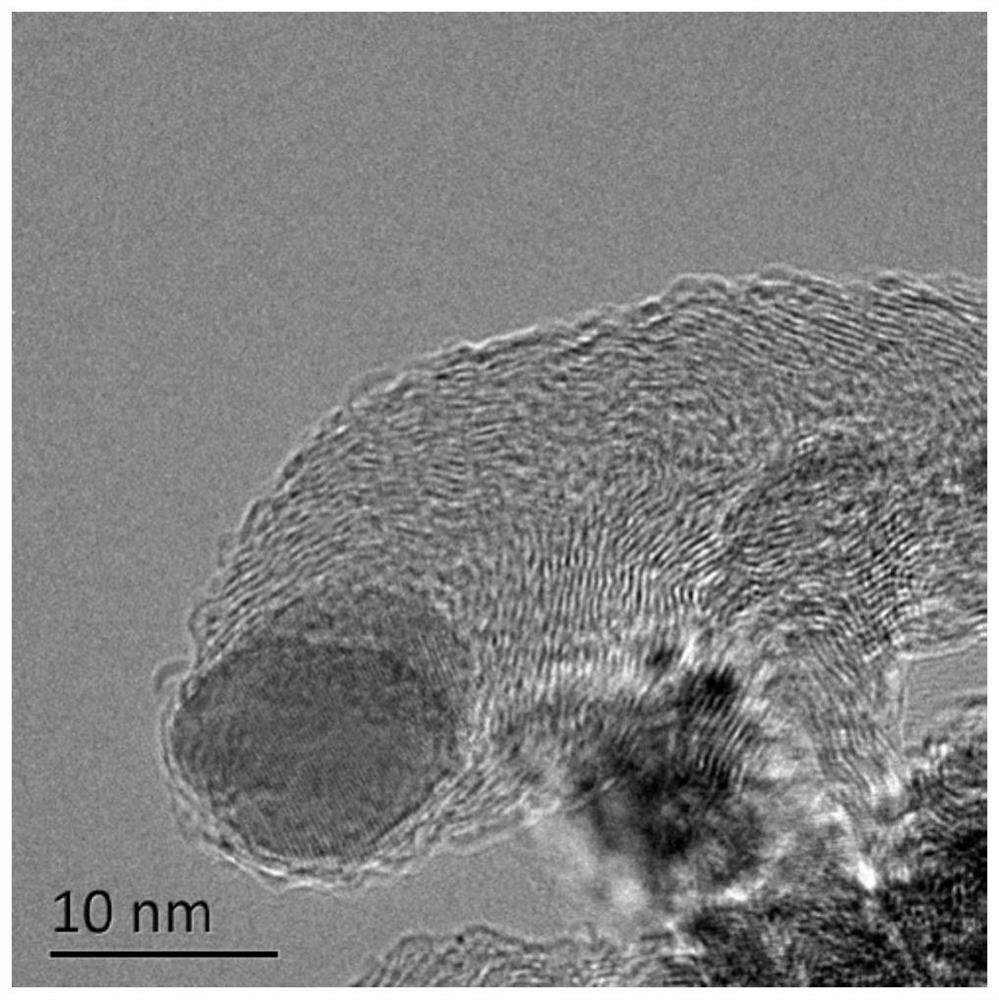

[0040] (3) Weigh 0.5G step (2), in the quartz boat, placed in the tube furnace, the pyrolysis atmosphere is argon, at 600 ° C constant temperature hot solution for 3 h, resulting in Co Nano The surface of the particles cover Co @ c @ NCNT material with a carbon film.

[0041] (4) When the temp...

Embodiment 2

[0047] This embodiment provides a method of preparing a CO @ NCNT material prepared by a reduction-oxidation-reduction strategy, including the following steps:

[0048] (1) Dimethylimidazole (12 mmol) was added to anhydrous methanol (75 mL), and the ultrasound was dissolved, and the organic ligand solution was obtained; CO (NO) 3 ) 2 · 6h 2 O (3 mmol) is dissolved in anhydrous methanol (75 mL) to obtain a Co salt solution;

[0049] (2) The Co salt solution in step (1) is added to the organic ligand solution, stirred at room temperature for 15 min, and then filtered the resulting solution after 24 h, and washed three times, dried three times at 60 ° C to obtain ZIF-67 materials at 60 ° C. ;

[0050] (3) Weigh 0.5G step (2), which is paired in the quartz boat, which is placed in a tube furnace, and the pyrolysis atmosphere is mixed with hydrogen and argon (H. 2 : Ar = 10: 90), at 600 ° C constant temperature hot solution 3 h, resulting in the surface of the CO nanoparticle covering ...

Embodiment 3

[0055] This embodiment provides a method of preparing a CO @ NCNT material prepared by a reduction-oxidation-reduction strategy, including the following steps:

[0056] (1) Dimethylimidazole (12 mmol) was added to anhydrous methanol (75 mL), and the ultrasound was dissolved, and the organic ligand solution was obtained; CO (NO) 3 ) 2 · 6h 2 O (3 mmol) is dissolved in anhydrous methanol (75 mL) to obtain a Co salt solution;

[0057] (2) The Co salt solution in step (1) is added to the organic ligand solution, stirred at room temperature for 15 min, and then filtered the resulting solution after 24 h, and washed three times, dried three times at 60 ° C to obtain ZIF-67 materials at 60 ° C. ;

[0058] (3) Weigh 0.5G step (2), which is paired in the quartz boat, which is placed in a tube furnace, and the pyrolysis atmosphere is mixed with hydrogen and argon (H. 2 : Ar = 10: 90), at 600 ° C constant temperature hot solution 3 h, resulting in the surface of the CO nanoparticle covering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com