Preparation method of Z-1, 3, 3, 3-tetrafluoropropene

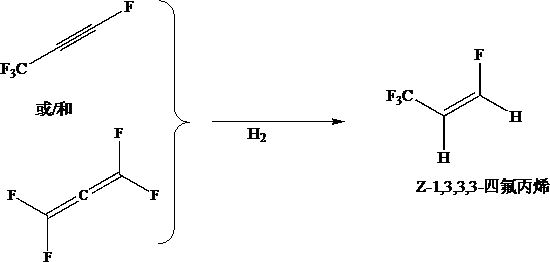

A technology of tetrafluoropropene and Z-1, which is applied in the field of highly selective preparation of Z-1,3,3,3-tetrafluoropropene, which can solve the problem of low yield of tetrafluoropropene in one pass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

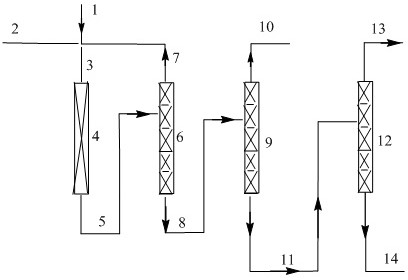

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 tetrafluoropropadiene

[0037] Step (1): Dissolve an appropriate amount of silver nitrate in an appropriate amount of water according to the mass percentage of silver oxide and carrier, add aluminum fluoride carrier, impregnate for 18 hours, then filter, dry in an oven at 80°C for 24 hours, and then place Under the protection of nitrogen, calcined at 400° C. for 10 hours to obtain the oxidation catalyst. Fill 10 milliliters of the oxidation catalyst 10%Ag prepared by the above-mentioned method in the tubular reactor made of Incon alloy with an inner diameter of 1 / 2 inch and a length of 30 cm 2 O / AlF 3 . The reaction conditions are as follows: the reaction temperature is 260°C, the molar ratio of the inert gas helium, oxygen and octafluorocyclopentene is 1:1:1, the contact time is 0.1s, and the reaction pressure is 0.1MPa. The reaction product was collected by a polytetrafluoroethylene sampling bag. After 10 hours, a sample was taken fr...

Embodiment 2

[0039] Example 2 Preparation of 1,3,3,3-tetrafluoropropyne

[0040] Preparation of isomerization catalyst: put alumina in the reactor, at a temperature of 400°C, feed a mixed gas composed of chlorodifluoromethane and nitrogen with a substance ratio of 1:4, activate for 12 hours, and stop feeding Mixed gas, prepared catalyst.

[0041] 10 mL of the above-prepared catalyst was filled in a tubular reactor made of Inconium alloy with an inner diameter of 1 / 2 inch and a length of 30 cm. The reaction conditions are as follows: the reaction temperature is 20° C., the contact time of tetrafluoropropadiene is 60 s, and the reaction pressure is 0.1 MPa. After running for 10 hours, the reaction product was collected and heated, and the gas phase organic phase was taken for GC analysis. The reaction result is: the conversion rate of tetrafluoropropadiene is 100%, and the selectivity of 1,3,3,3-tetrafluoropropyne is 99.5%.

Embodiment 3

[0043] Preparation of hydrogenation catalyst: according to Pd, Bi, AlF 3 The mass percentages of the three are respectively 2%: 0.2%: 97.8%. Palladium chloride and bismuth chloride are dissolved in water together, and the pH value of the solution is adjusted to 4 to 6 with dilute hydrochloric acid to obtain an impregnating solution; and room temperature conditions, the impregnating solution to the carrier AlF 3 Add dropwise, after the dropwise addition, maintain immersion for 4 hours, filter and dry to obtain the catalyst precursor; dry the catalyst precursor at 120°C for 8 hours under the protection of nitrogen, then heat up to 300°C for 8 hours, and then use nitrogen The mixed gas with a molar ratio of 4:1 to hydrogen was activated at 250°C for 14 hours to obtain a hydrogenation catalyst. It was confirmed by XRD that the existing forms of Pd and Bi in the hydrogenation catalyst were simple substances.

[0044] 10 mL of the above-prepared catalyst was filled in a tubular rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com