Anti-aging plastic material and preparation method thereof

A plastic material and anti-aging technology, which is applied in the field of anti-aging plastic materials and its preparation, can solve the problems of unsatisfactory performance, low bending strength and hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

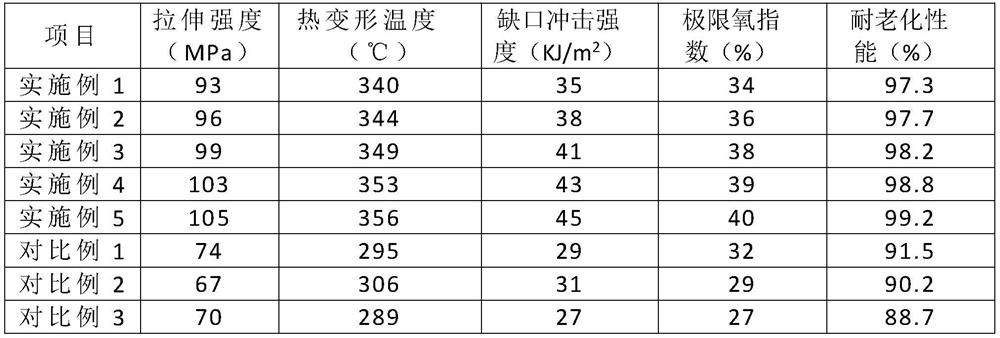

Examples

Embodiment 1

[0027] A preparation method of an anti-aging plastic material, characterized in that it comprises the steps of:

[0028] Step S1, preparation of copolymer: 5-allyl-3-methoxy methyl salicylate, 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl] Ethyl 2-methacrylate, 2-acrylamido-2-methylpropanesulfonic acid, acrylonitrile, triflumethric acid, and initiator are added to the high boiling point solvent, and stirred at 65°C in an inert gas atmosphere reacted for 4 hours, then precipitated in water, washed the precipitated polymer three times with ethanol, and finally placed in a vacuum drying oven at 80°C to dry to constant weight to obtain a copolymer;

[0029] Step S2, preparation of polycondensate: add benzomelamine, 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid and catalyst to N,N-dimethyl In base formamide; evacuated and filled with high-purity nitrogen to normal pressure, as a protective gas, stirred at 210°C for 1 hour, then continued for 4 hours at a constant temperature of 230°...

Embodiment 2

[0036] A preparation method of an anti-aging plastic material, characterized in that it comprises the steps of:

[0037] Step S1, preparation of copolymer: 5-allyl-3-methoxy methyl salicylate, 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl] Ethyl 2-methacrylate, 2-acrylamido-2-methylpropanesulfonic acid, acrylonitrile, triflumethic acid, and initiator are added to the high boiling point solvent, and stirred at 67°C in an inert gas atmosphere After reacting for 4.5 hours, it was precipitated in water, and the precipitated polymer was washed 4 times with ethanol, and finally placed in a vacuum drying oven at 83°C and dried to constant weight to obtain a copolymer;

[0038] Step S2, preparation of polycondensate: add benzomelamine, 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid and catalyst to N,N-dimethyl In base formamide; evacuated and filled with high-purity nitrogen to normal pressure, as a protective gas, stirred at 215°C for 1.2 hours, then continued at 232°C and constant pre...

Embodiment 3

[0045] A preparation method of an anti-aging plastic material, characterized in that it comprises the steps of:

[0046] Step S1, preparation of copolymer: 5-allyl-3-methoxy methyl salicylate, 2-[3-(2H-benzotriazol-2-yl)-4-hydroxyphenyl] Ethyl 2-methacrylate, 2-acrylamido-2-methylpropanesulfonic acid, acrylonitrile, triflumethic acid, and initiator are added to the high boiling point solvent, and stirred at 70°C in an inert gas atmosphere React for 5 hours, then precipitate in water, wash the precipitated polymer with ethanol for 5 times, and finally place it in a vacuum drying oven at 85°C to dry to constant weight to obtain a copolymer;

[0047] Step S2, preparation of polycondensate: add benzomelamine, 2,5-bis(1,2,4-triazol-1-yl) terephthalic acid and catalyst to N,N-dimethyl In base formamide; evacuated and filled with high-purity nitrogen to normal pressure, as a protective gas, stirred at 220°C for 1.5 hours, then continued at 235°C and constant pressure of 2.2MPa for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com