Activated carbon carrier iron-based NH3-SCR catalyst as well as preparation method and application thereof

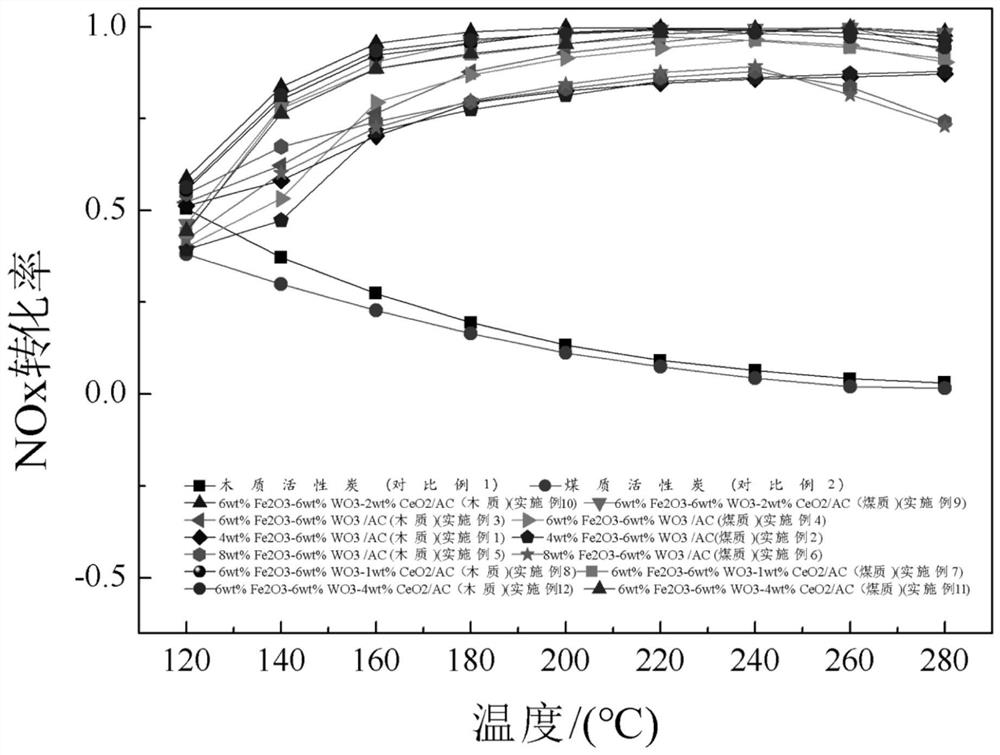

A technology of NH3-SCR and catalyst, which is applied in the field of low-temperature denitrification catalytic materials, can solve the problems of low catalyst price, inability to meet the cost at the same time, and high low-temperature denitrification ability, and achieve low-cost components, high and low-temperature activity, and good low-temperature activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides an activated carbon carrier iron-based NH 3 -The preparation method of SCR catalyst, comprises the steps:

[0048] 1) Add one of 2.42g of ferric nitrate, 1.31g of sodium tungstate, and 17.20g of woody activated carbon into 50g of deionized water, and heat in a water bath at 70°C until completely dissolved to obtain a mixed solution;

[0049] 2) Add 0.62gNa to the mixed solution 2 S, and add ammonia water to adjust the pH value to 10 to obtain a precipitate;

[0050] 3) Centrifuge the sediment at 4000r / min for 3min, dry the sediment in an oven at 80°C for 24h, grind to 40-60 mesh after drying, and obtain sample particles;

[0051] 4) Calcinate the precipitate particles at 420°C for 5 hours under a nitrogen atmosphere, and grind to 40-60 mesh after roasting to obtain the activated carbon carrier iron-based NH 3 - SCR catalyst; in this catalyst, Fe 2 o 3 Accounting for 4wt% of the total mass of the catalyst, WO 3 Accounting for 6wt% of the to...

Embodiment 2

[0053] This embodiment provides an activated carbon carrier iron-based NH 3 -The preparation method of the SCR catalyst, the steps of the method are the same as in Example 1, the only difference is that in step 1), 17.20 g of coal-based activated carbon is used instead of 17.20 g of woody activated carbon. The activated carbon carrier iron-based NH obtained in this embodiment 3 -In SCR catalysts, Fe 2 o 3 Accounting for 4wt% of the total mass of the catalyst, WO 3 Accounting for 6wt% of the total mass of the catalyst; the catalyst is named 4wt% Fe according to the type of activated carbon carrier 2 o 3 -6wt% WO 3 / AC (coal quality).

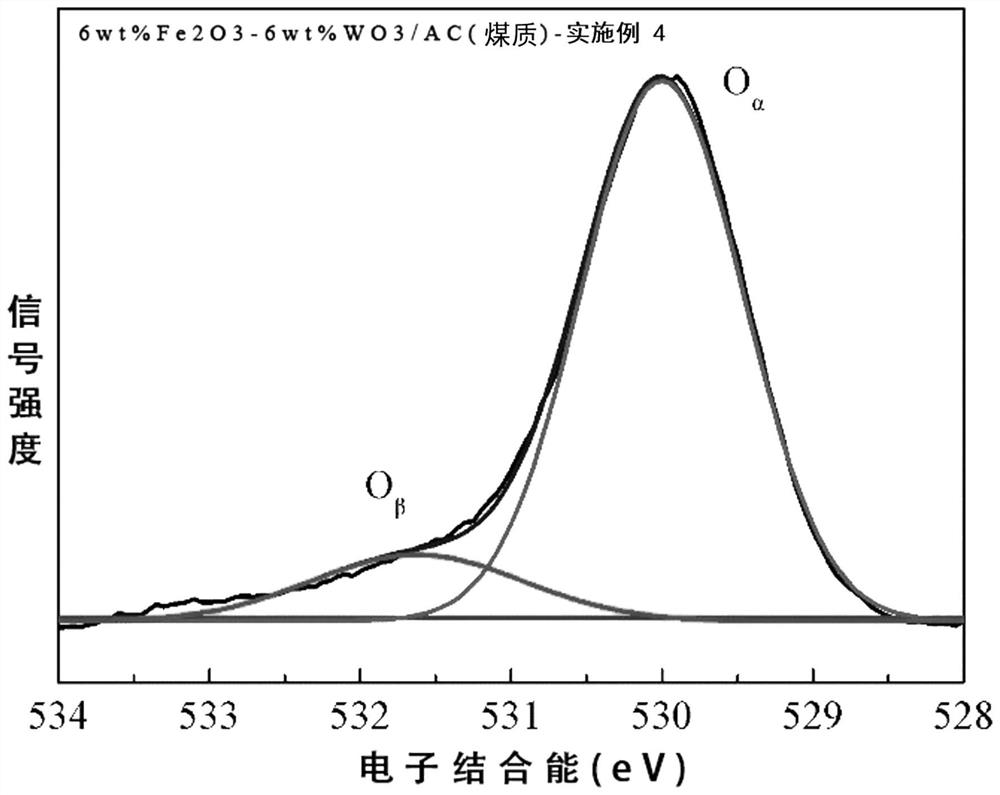

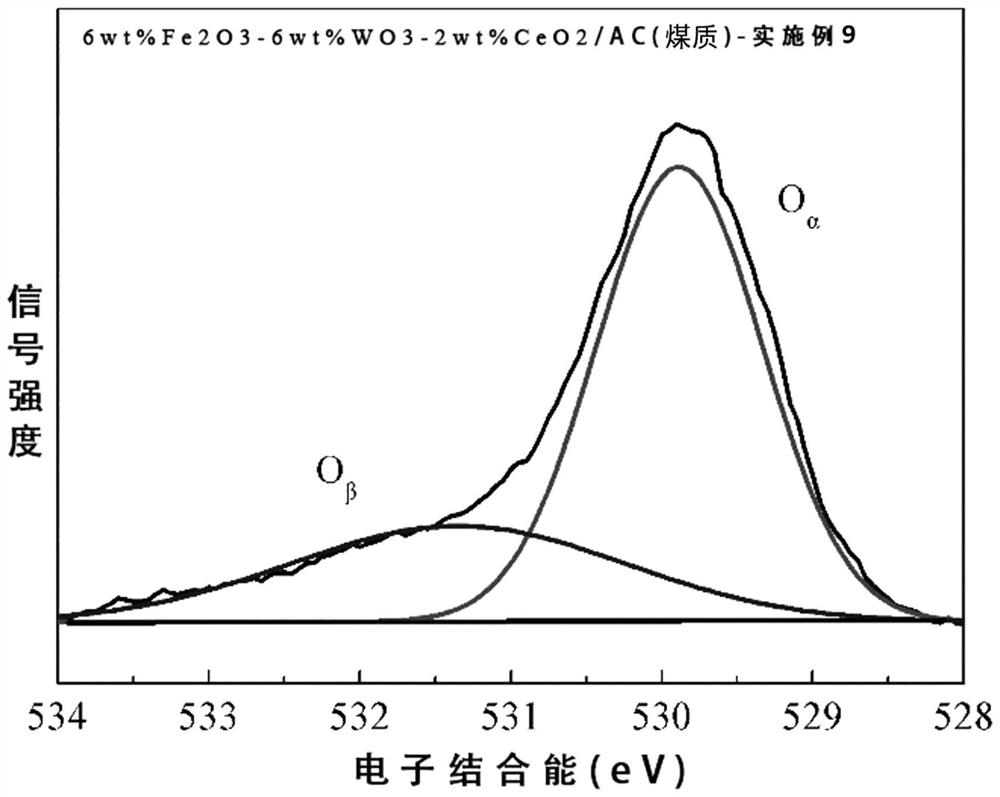

Embodiment 3

[0055] This embodiment provides an activated carbon carrier iron-based NH 3 -The preparation method of the SCR catalyst, the steps of the method are the same as in Example 1, the only difference is that the amount of iron nitrate in step 1) is 3.63g. The activated carbon carrier iron-based NH obtained in this embodiment 3 -In SCR catalysts, Fe 2 o 3 Accounting for 6wt% of the total mass of the catalyst, WO 3 Accounting for 6wt% of the total mass of the catalyst; the catalyst is named 6wt% Fe according to the type of activated carbon carrier 2 o 3 -6wt% WO 3 / AC (wooden).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com