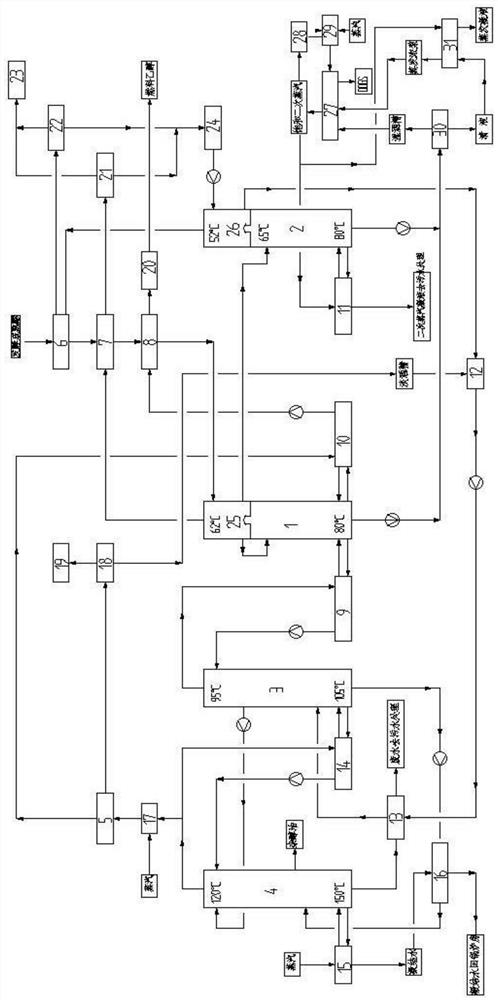

Method and device for distilling fuel ethanol by using secondary steam of superheated steam fluidized bed dryer as partial heat source

A technology of fluidized bed dryer and superheated steam, which is applied in separation methods, chemical instruments and methods, distillation separation, etc., and can solve problems such as low grade, environmental pollution, and heat supply in the distillation section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] 1. The fermented mash is preheated to 42°C by the mash primary preheater 6 (preheating the mature mash once while the wine vapor is condensing at the top of the acid discharge section 26), and the mash secondary preheater 7 is preheated to 55°C ℃ (the wine vapor at the top of the degassing section 25 is condensed and the mature mash is preheated twice), the mash three-stage preheater 8 is preheated to 58°C (the liquid fuel ethanol condensed after dehydration and heating the negative pressure mash tower I1 Preheat the mature mash three times) and then feed the material at the top of the degassing section 25 at the top of the negative pressure mash tower I1. After entering the tower, the carbon dioxide in the mature mash and some low-boiling impurities will act on the crude alcohol vapor rising in the negative pressure mash tower I1. Next, it is separated from the fermented mash, and the miscellaneous crude wine vapor enters the secondary preheater 7 of the mash and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com