Lambda-cyhalothrin microcapsule suspending agent and preparation method thereof

A technology of high-efficiency cyhalothrin and microcapsule suspending agent, which is applied in the fields of botanical equipment and methods, insecticides, biocides, etc., can solve the problems of low coating rate, complicated process, unstable quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

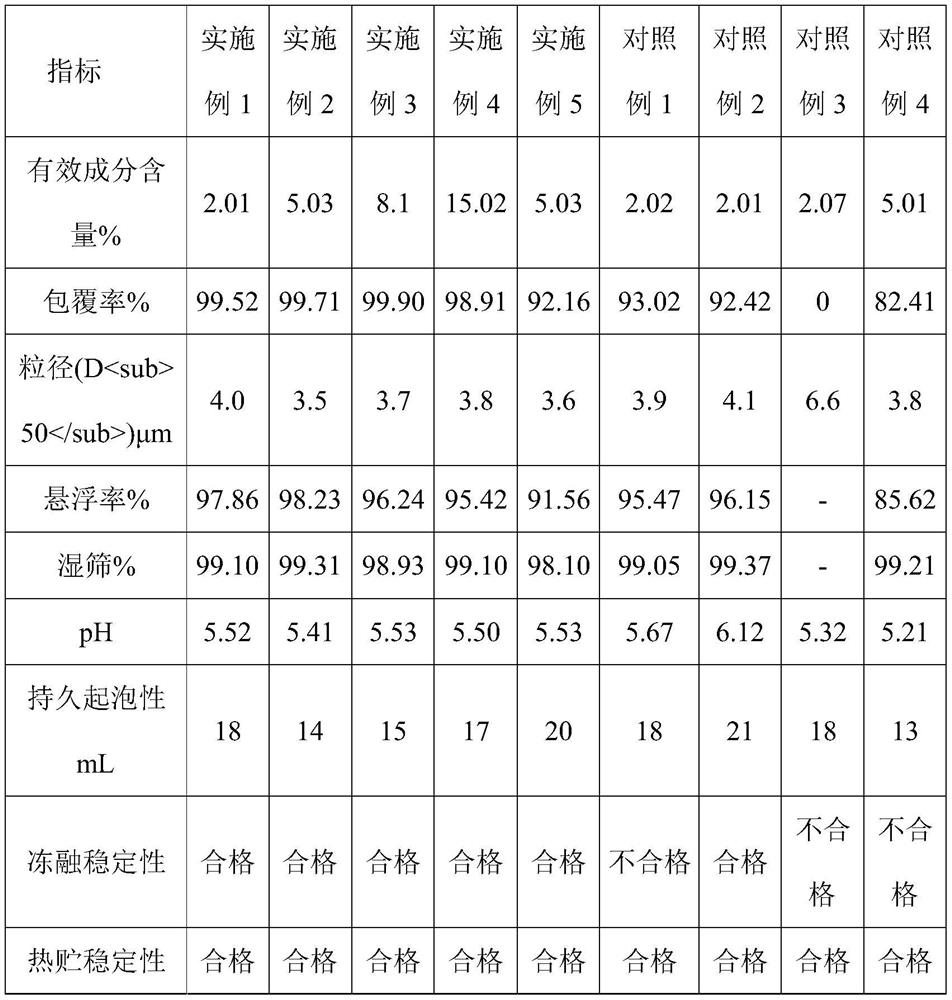

Embodiment 1

[0036] Prepare 2% lambda-cyhalothrin microcapsule suspension, the percentage by weight of the material is as follows:

[0037] 95.3% active ingredient of lambda-cyhalothrin: 2.1g, active ingredient 2.0g

[0038] Solvent: cyclohexanone 3g

[0039] Covering material: white carbon black 4g

[0040] Dispersant: sodium lignosulfonate 3g

[0041] Emulsifier: Lauryl Polyoxyethylene Ether 1g

[0042] Preservative: Sodium Benzoate 0.1g

[0043] Thickener: xanthan gum 0.2g

[0044] Deionized water 86.6g

[0045] Preparation steps:

[0046] (1) 2.1g content of 95.3% beta-cyhalothrin former medicine is dissolved evenly with 3g cyclohexanone;

[0047] (2) With 4g of white carbon black, the material obtained in step (1) is mixed uniformly in a mortar;

[0048] (3) Transfer the material obtained in step (2) into a 250ml beaker, and add sodium lignosulfonate 3g, polyoxyethylene lauryl ether 1g, sodium benzoate 0.1g, xanthan gum 0.2g, deionized water 86.6g, Use a high shear machine to...

Embodiment 2

[0051] Prepare 5% lambda-cyhalothrin microcapsule suspension, the percentage by weight of the material is as follows:

[0052] Beta-cyhalothrin technical drug with a content of 96.15%: 5.2g, active ingredient 5.0g;

[0053] Solvent: Cyclohexanone 7g

[0054] Covering material: white carbon black 8g

[0055] Dispersant: sodium lignosulfonate 3g

[0056] Emulsifier: Lauryl Polyoxyethylene Ether 1g

[0057] Preservative: Sodium Benzoate 0.1g

[0058] Thickener: xanthan gum 0.2g

[0059] Deionized water 75.5g

[0060] Preparation steps:

[0061] (1) 5.2g content of 96.15% beta-cyhalothrin former medicine is dissolved evenly with 7g cyclohexanone;

[0062] (2) Mix the material obtained in step (1) in a mortar with 8g white carbon black;

[0063] (3) Transfer the material obtained in step (2) into a 250ml beaker, and add sodium lignosulfonate 3g, polyoxyethylene lauryl ether 1g, sodium benzoate 0.1g, xanthan gum 0.2g, deionized water 75.5g, Use a high shear machine to cut f...

Embodiment 3

[0066] The preparation content is 8% lambda-cyhalothrin microcapsule suspension concentrate, and the percentage by weight of the material is as follows:

[0067] Beta-cyhalothrin technical product with a content of 96.15%: 8.32g, active ingredient 8.0g;

[0068] Solvent: Cyclohexanone 10g

[0069] Coating material: white carbon black 10g

[0070] Dispersant: sodium lignosulfonate 3g

[0071] Emulsifier: Lauryl Polyoxyethylene Ether 1g

[0072] Preservative: Sodium Benzoate 0.1g

[0073] Thickener: xanthan gum 0.2g

[0074] Deionized water 67.38g

[0075] Preparation steps:

[0076] (1) be 96.15% beta-cyhalothrin former drug with 8.32g content and dissolve evenly with 10g cyclohexanone;

[0077] (2) Mix the material obtained in step (1) in a mortar with 10g white carbon black;

[0078] (3) Transfer the material obtained in step (2) into a 250ml beaker, and add 3g of sodium lignosulfonate, 1g of polyoxyethylene lauryl ether, 0.1g of sodium benzoate, 0.2g of xanthan gum, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com