Harmless treatment and resource utilization method for metal-containing pollutants

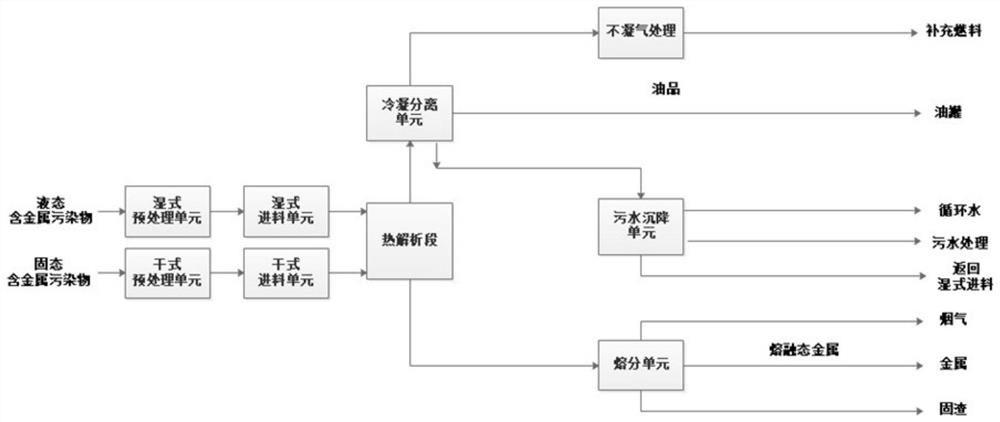

A pollutant and harmless technology, applied in the field of metal-containing pollutants treatment, can solve the problems of comprehensive treatment of metal-containing pollutants, and achieve the effects of perfect treatment, comprehensive utilization of resources, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

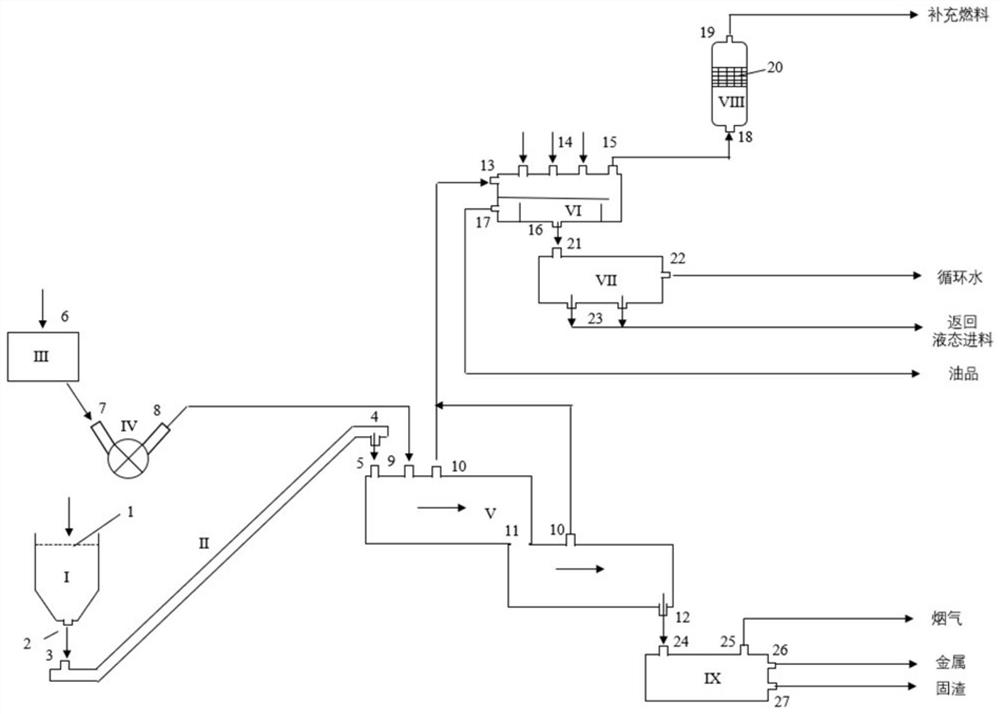

[0050] In conjunction with the accompanying drawings, a method for the harmless disposal and resource utilization of metal-containing pollutants includes the following steps:

[0051] (1) Dividing the metal-containing pollutants into solid metal-containing pollutants and liquid metal-containing pollutants, sending the solid metal-containing pollutants into the dry pretreatment unit, and sieving through the vibrating screen 1 in the dry pretreatment unit, The undersize is sent to the dry feeding unit, and the oversize is sent to the crusher for crushing and then continues to be screened until the screening is completed.

[0052] The liquid metal-containing pollutants are sent to the feed pool 6 in the wet pretreatment unit, first screened by the feed sieve set above the feed pool 6, and the sundries are screened out, and the sundries are sent to the crusher for crushing , into the dry feed unit II; the material after screening in the feed pool enters the wet feed unit IV.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com