Lithium extraction system and lithium extraction method for salt lake brine

A salt lake brine and brine technology, applied in the direction of lithium carbonate;/acid carbonate, etc., can solve problems such as unstable product quality, improve batch qualification, reduce product cost, and improve quality stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

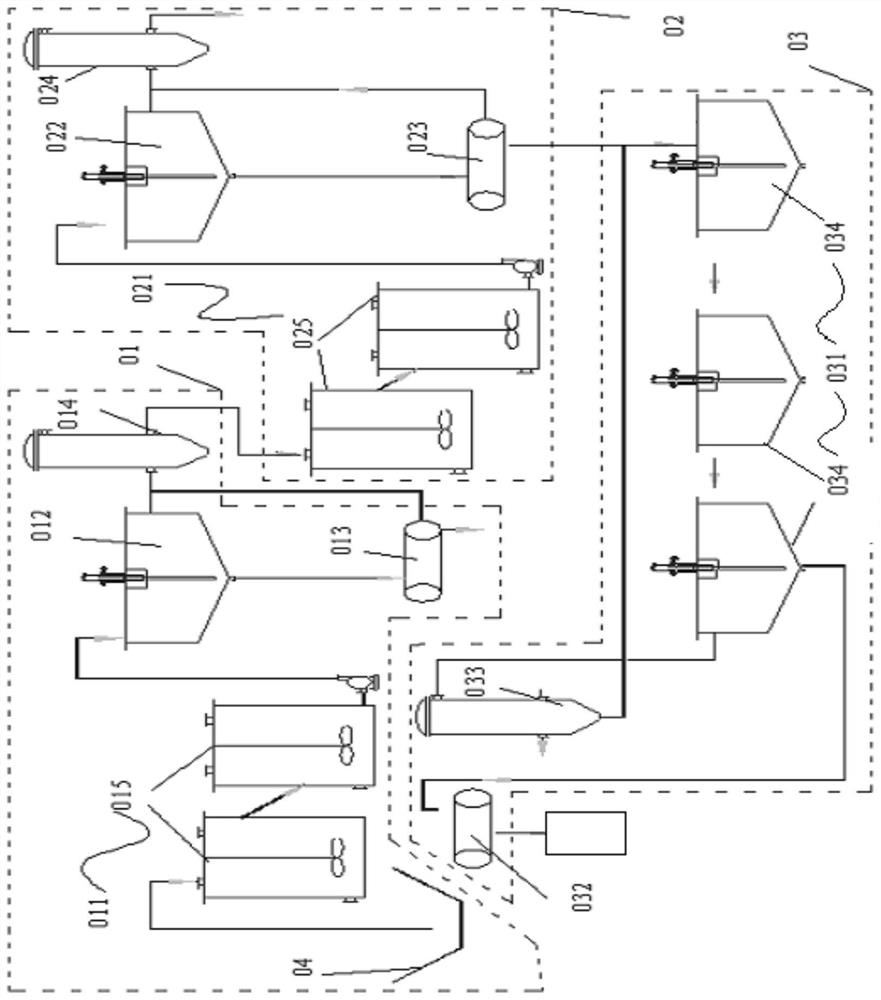

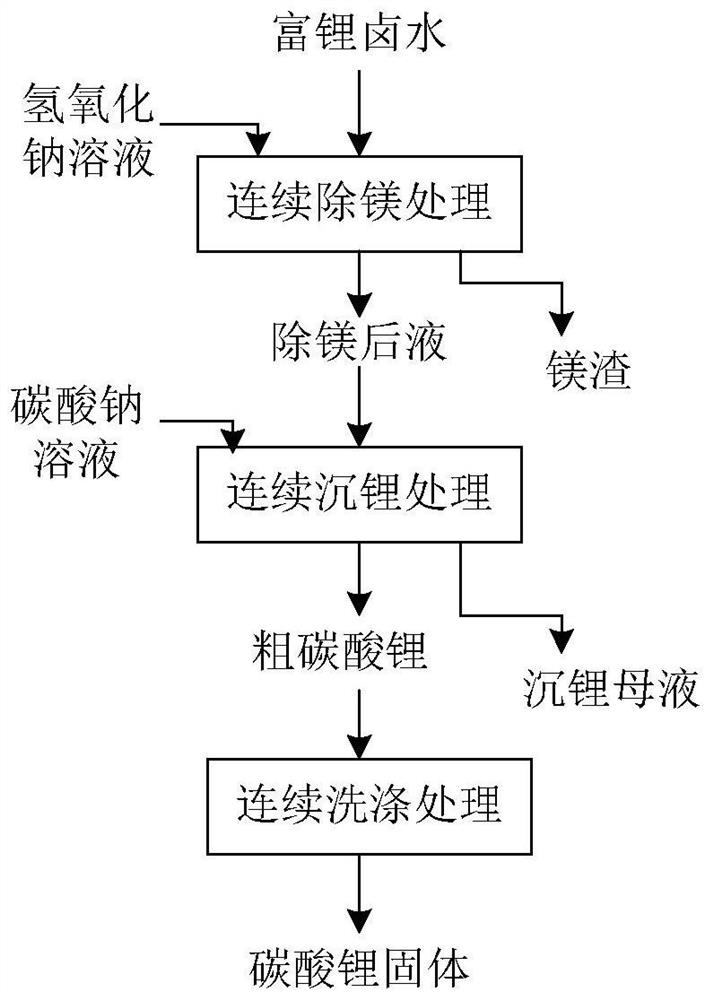

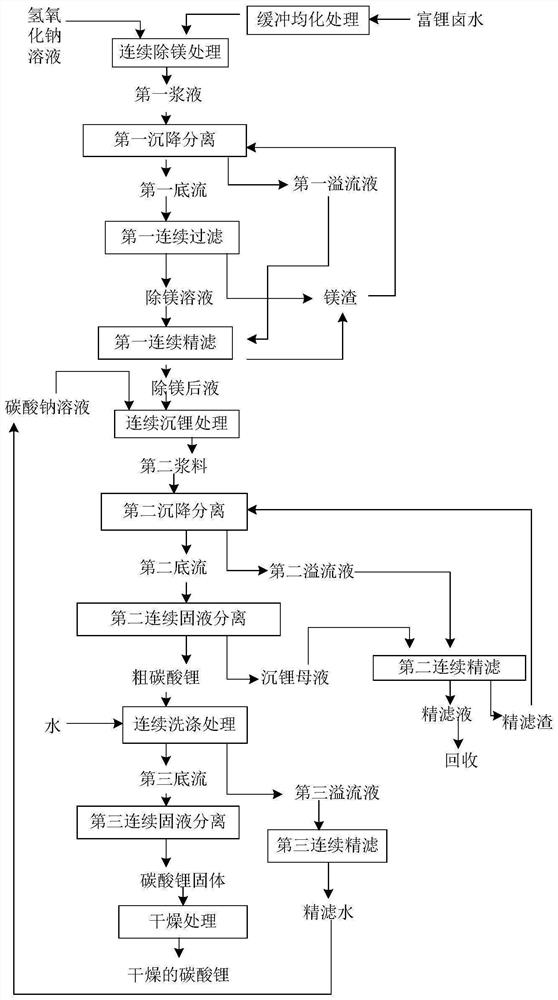

[0051]Lithium-rich brine (Li) after natural settlement and homogenization in the buffer unit 04 and stores for a certain period of time (Li+>15g / L), the composition of the lithium-rich brine is shown in Table 1, and the lithium-rich brine is continuously injection magnesium according to the continuous magnesium equipment 01. Specifically, lithium-rich brine after the buffer homogenization is 30% by weight. The sodium hydroxide solution (in a haze-controlled flow rate manner) is continuously laminarized in three consecutive median grooves 015 of the continuous median device 011 (temperature 95 ° C) to obtain first Slurry; pump the first slurry into the first continuous settling device 012 to carry out the first settling separation (anionic polyacrylamide, 200 mg / kg of anionic polyacrylamide and diatomide, diatomaceous earth adding amount of 0.5 ~ 1%) The first bottom flow and the first overflow are obtained; the first substrate is performed, and the first bottom stream is first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com