Device and method for continuously producing lithium hydroxide from salt lake lithium-rich brine

A technology of lithium hydroxide and brine, which is applied in the direction of lithium oxide;

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

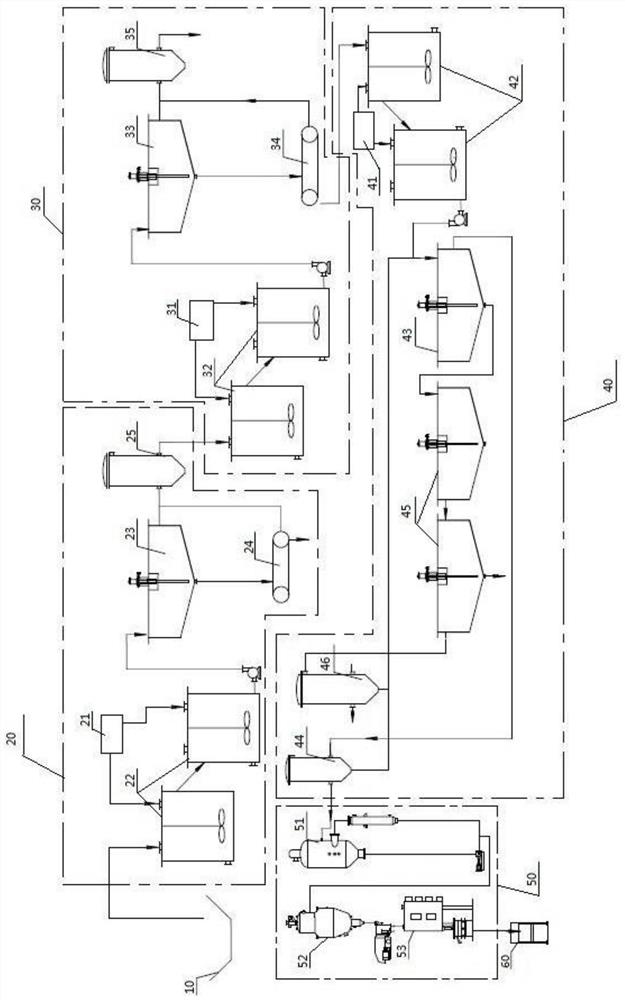

[0092] A certain salt lake lithium extraction enterprise adopts the present invention figure 1 The device shown in the semi-industrial test, the raw material composition of lithium-rich brine is as follows:

[0093] element Li +

Mg 2+

Cl -

Na+ Concentration(g / L) 15~20 8 100 1.9

[0094] The above-mentioned lithium-rich brine is naturally settled and buffered and homogenized in the continuous buffer homogenization unit, and the buffered homogenized brine is subjected to continuous magnesium removal treatment in the continuous magnesium removal equipment. The lithium-rich brine after buffering and homogenization is continuously passed into three continuous magnesium precipitation tanks connected in sequence, and each magnesium precipitation tank is equipped with an atomization device for adding 30wt% sodium hydroxide aqueous solution to each magnesium precipitation tank. In the tank, continuous magnesium removal is carried out. During t...

Embodiment 2

[0100] A certain salt lake lithium extraction enterprise adopts the present invention figure 1 The device shown in the semi-industrial test, the raw material composition of lithium-rich brine is as follows:

[0101] element Li +

Mg 2+

Cl -

Na+ Concentration(g / L) 15~20 8 100 1.9

[0102] The above-mentioned lithium-rich brine is naturally settled and buffered and homogenized in the continuous buffer homogenization unit, and the buffered homogenized brine is subjected to continuous magnesium removal treatment in the continuous magnesium removal equipment. The lithium-rich brine after buffering and homogenization is continuously passed into three continuous magnesium precipitation tanks connected in sequence, and each magnesium precipitation tank is equipped with an atomization device for adding 30wt% sodium hydroxide aqueous solution to each magnesium precipitation tank. In the tank, continuous magnesium removal is carried out. During t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com