Method for recovering valuable metals from waste plastic plating layer containing copper and nickel

A technology for valuable metals and waste plastics, applied in the field of recovering valuable metals from copper-nickel waste plastic coatings, can solve the problems of no specific embodiment, large acid-base consumption in iron removal process, strong nitric acid corrosion, etc., Achieve the effect of strong practicability, low reagent cost and flexible processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

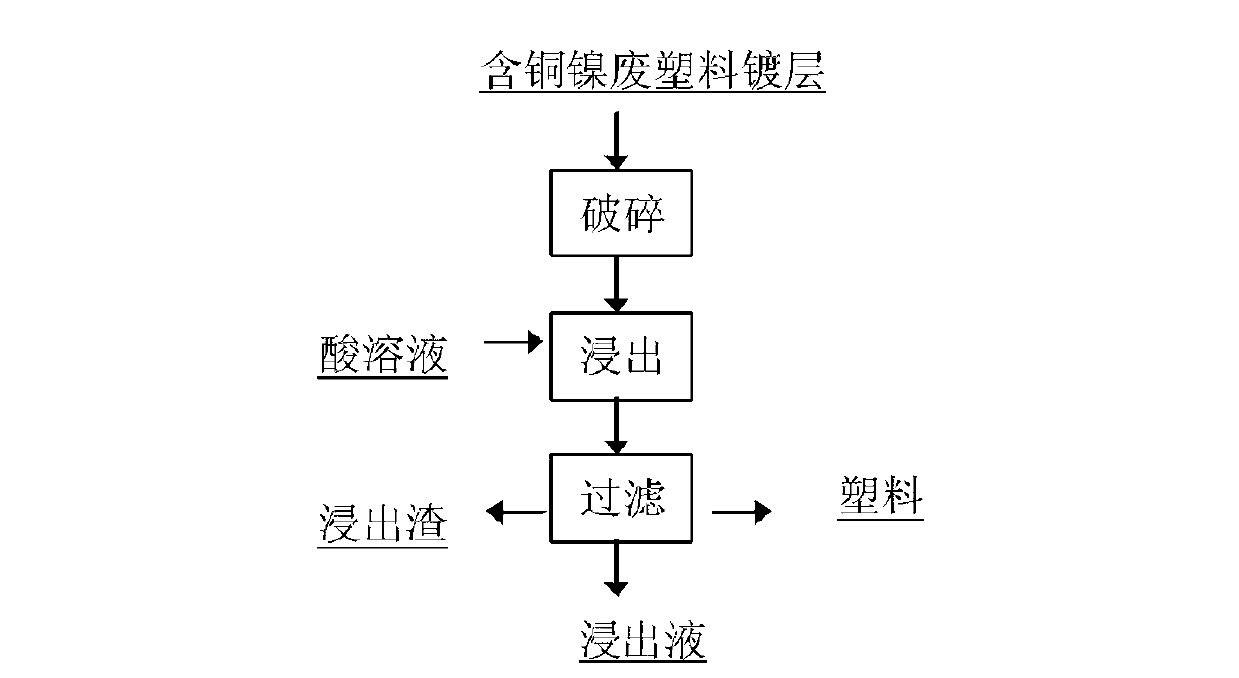

Method used

Image

Examples

Embodiment 1

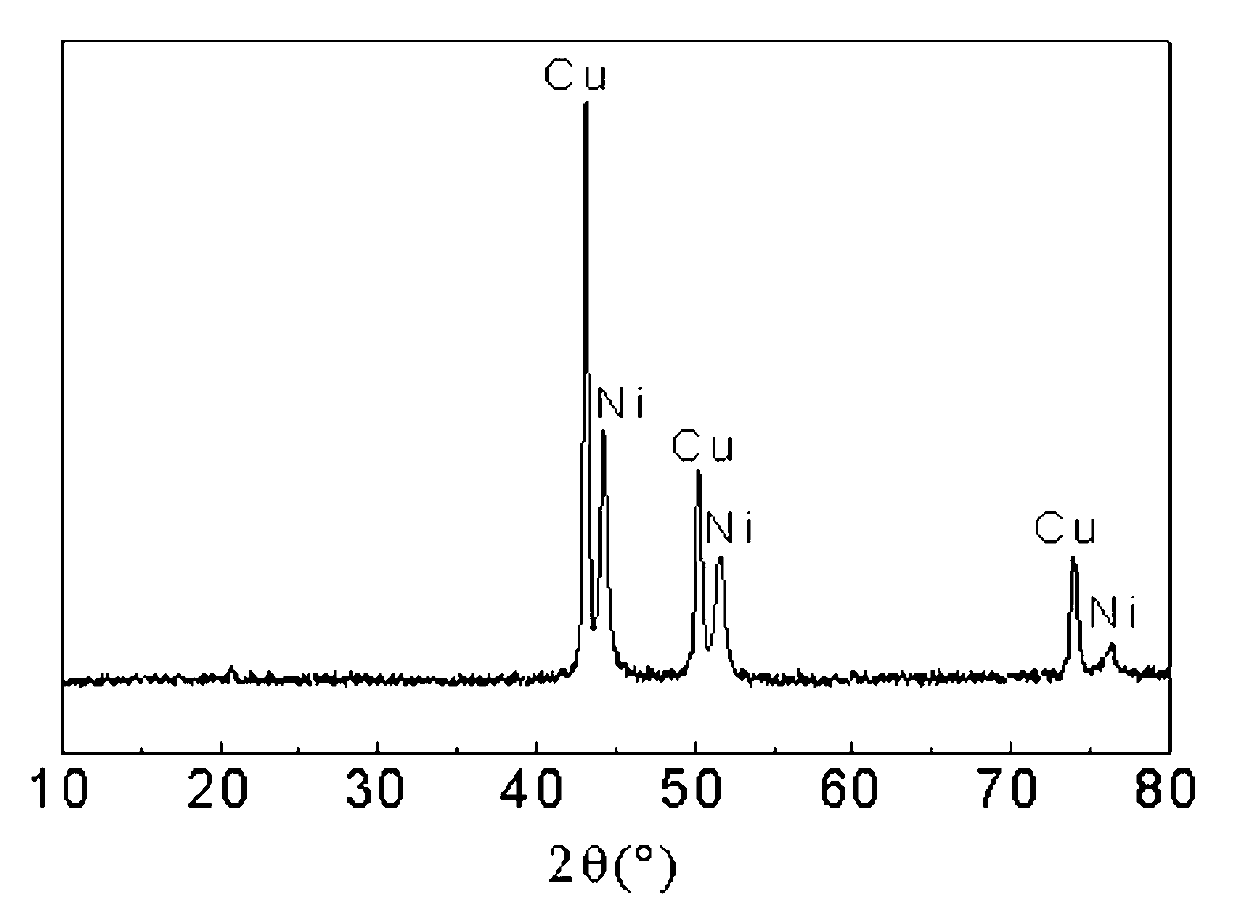

[0031] The mass content of copper in the copper-nickel waste plastic coating that adopts is 50.5%, and the mass content of nickel is 43.1%, and the mass content of plastics is 6.4%, and XRD analysis result is as follows figure 2 shown;

[0032] Mechanically crush and sieve the copper-nickel-containing waste plastic coating to make debris with a particle size of ≤5mm;

[0033] Put the debris in the leaching tank, add acid solution and leaching under stirring conditions, the leaching temperature is 90°C, and the leaching time is 2h;

[0034] Described acid solution is prepared by the sulfuric acid of mass concentration 95%, corrosive agent and water, and the volume of acid solution is 3m 3 / t debris;

[0035] The amount of sulfuric acid is 1.5 times the mass of nickel in the debris;

[0036] The corrosive agent is sulfur, and the amount of sulfur is 0.2 times the mass of copper in the debris;

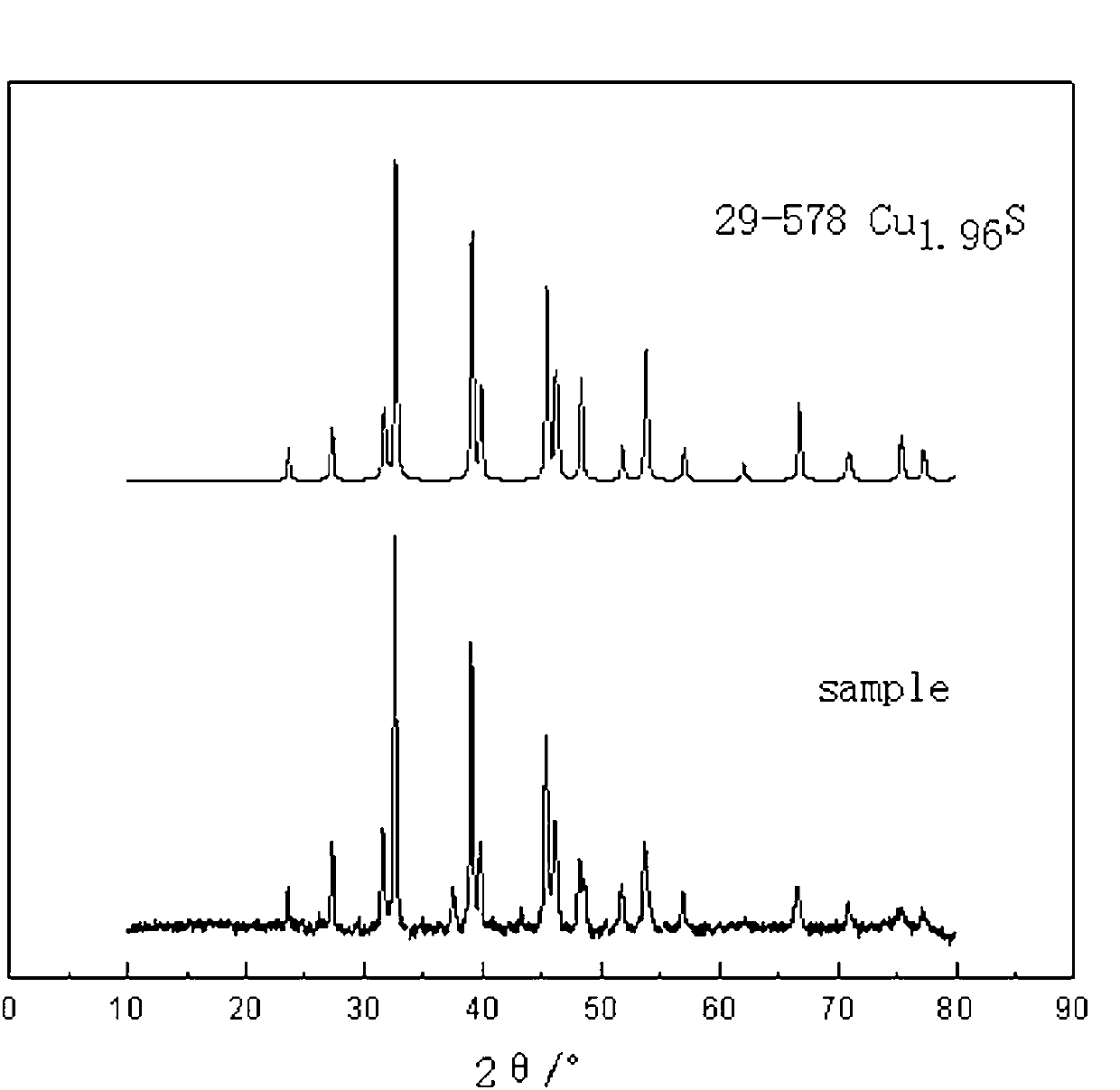

[0037] After the leaching is completed, let it stand until the leaching slag set...

Embodiment 2

[0042] The mass content of copper in the copper-nickel waste plastic coating that adopts is 62.5%, the mass content of nickel is 31.5%, and the mass content of plastic is 6%;

[0043] Mechanically crush and sieve the copper-nickel-containing waste plastic coating to make debris with a particle size of ≤5mm;

[0044] Put the debris in the leaching tank, add acid solution and leaching under stirring conditions, the leaching temperature is 95°C, and the leaching time is 0.5h;

[0045] Described acid solution is prepared by the sulfuric acid of mass concentration 95%, corrosive agent and water, and the volume of acid solution is 3m 3 / t debris;

[0046] The amount of sulfuric acid is twice the mass of nickel in the debris;

[0047] The corrosive agent is sulfur, and the amount of sulfur is 0.2 times the mass of copper in the debris;

[0048] After the leaching is completed, let it stand until the leaching slag is precipitated; pour out the part with plastic in the leaching solut...

Embodiment 3

[0053] The mass content of copper in the copper-nickel-containing waste plastic coating that is adopted is 30.6%, the mass content of nickel is 65.7%, and the mass content of plastic is 3.7%;

[0054] Mechanically crush and sieve the copper-nickel-containing waste plastic coating to make debris with a particle size of ≤5mm;

[0055] Put the debris in the leaching tank, add acid solution and leaching under stirring conditions, the leaching temperature is 60°C, and the leaching time is 8h;

[0056] Described acid solution is prepared by the sulfuric acid of mass concentration 95%, corrosive agent and water, and the volume of acid solution is 8m 3 / t debris;

[0057] The amount of sulfuric acid is twice the mass of nickel in the debris;

[0058] The corrosive agent is sulfur and sodium sulfite, the amount of sulfur used is 0.2 times the mass of copper in the debris, and the amount of sodium sulfite is twice the mass of copper in the debris;

[0059] After the leaching is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com