Tubular falling film reactor catalytic activation persulfate treatment system and operation process

A technology of falling film reactor and persulfate, which is applied in the direction of oxidized water/sewage treatment, special compound water treatment, process wastewater treatment, etc. It can solve the problems of harsh reaction conditions, high energy consumption, and the risk of corrosion equipment , to achieve the effect of promoting circulation, high mechanical strength, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

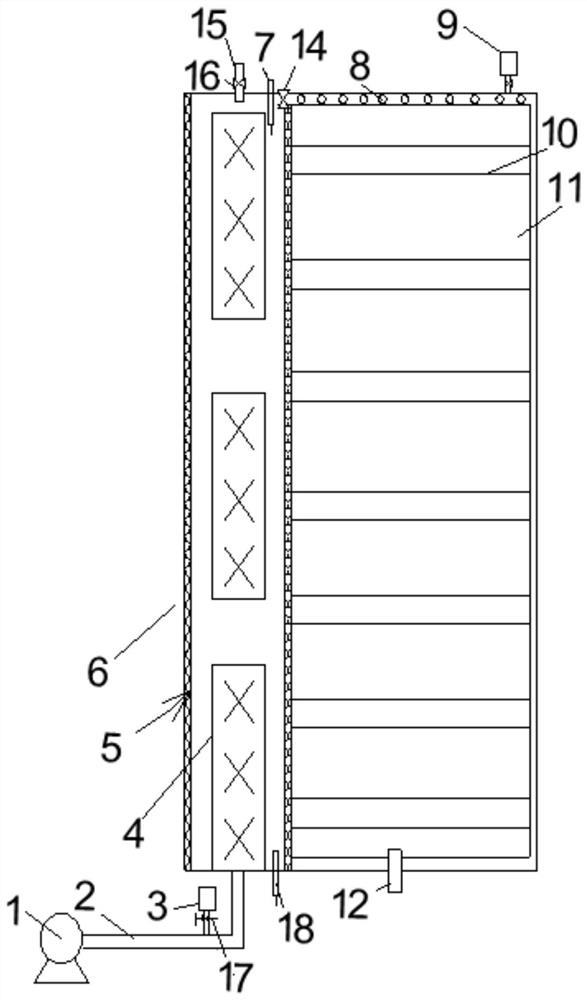

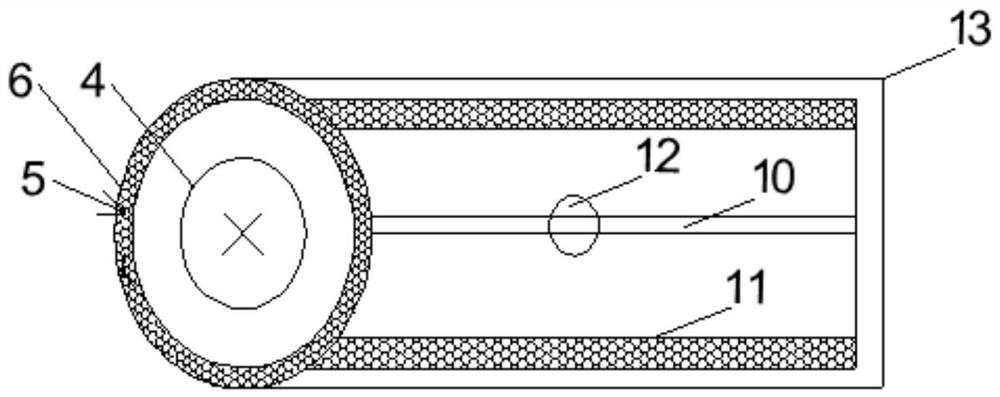

[0040] Such as Figure 1-2 As shown, the tubular falling film reactor catalytically activated persulfate treatment system includes a reactor, a water inlet unit, a water outlet unit and a control device, and the reactor includes a tubular device 6 and a falling film reaction zone, and the tubular device 6 Co / Fe flexible multi-wall carbon nanotube composite film 5 is filled close to the inner wall, and spiral static mixers 4 are installed at both ends and in the middle of the tubular device 6, which has high microscopic mixing efficiency and can make the influent and persulfate fully The mixed reaction makes the Co / Fe flexible multi-walled carbon nanotube composite film 5 better catalyze the activation of persulfate and reduce the reaction time. The outside of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com