Efficient and deep integrated treatment system for high-ammonia-nitrogen and high-nitrate-nitrogen wastewater

A treatment system and advanced treatment technology, applied in water/sewage treatment, water treatment parameter control, water/sewage multi-stage treatment, etc., can solve the problem that the oxidation activity is easily affected by the external environment, and the effluent TN of high-nitrate wastewater cannot meet the standard , the system is not stable enough and other problems, to achieve the effect of reducing energy consumption, saving energy consumption and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

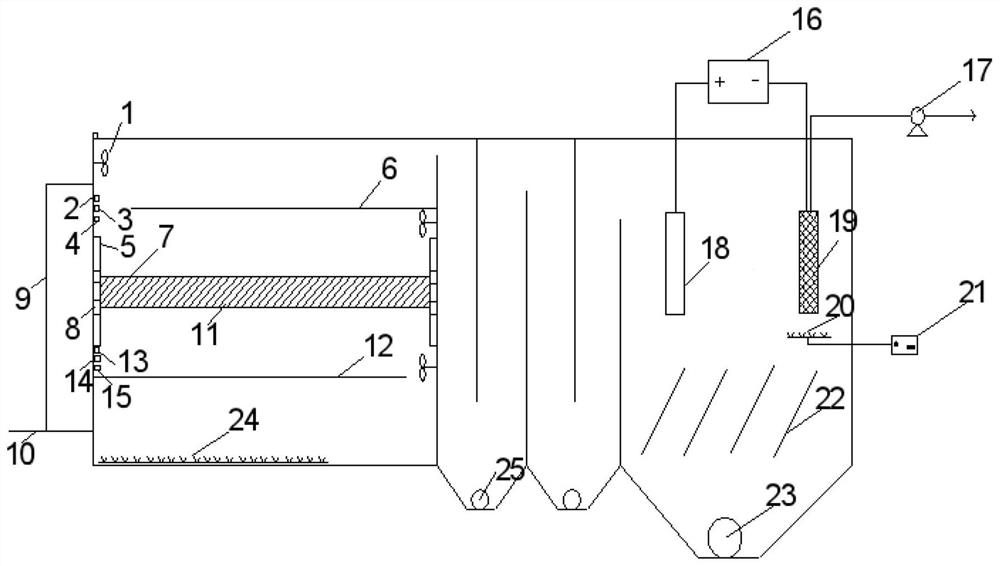

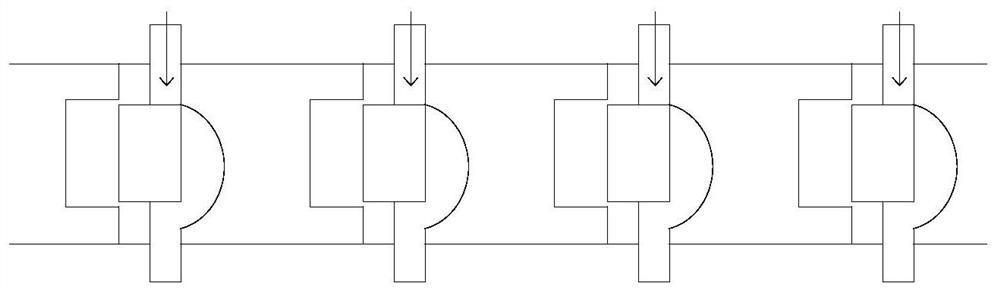

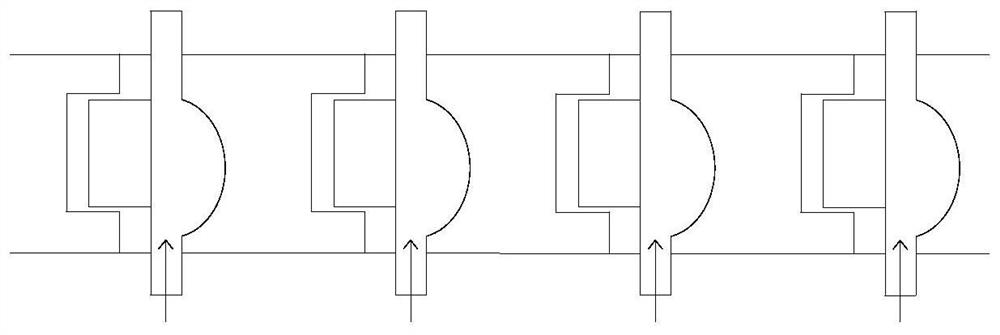

[0054] like Figure 1-5 As shown, using this process to treat sludge digestion liquid (temperature at 30°C), the organic matter in the influent comes from the small molecular organic matter in the anaerobic digestion effluent, which is used as a carbon source for short-range denitrification, no additional carbon source is needed, and the sewage passes through the water inlet pipe 10 Entering the nitrite nitrogen accumulation area, the sludge treated in this area is short-range nitrification-short-range denitrification granular sludge, which converts nitrate nitrogen and part of ammonia nitrogen in sewage into nitrate nitrogen, providing a substrate for anaerobic ammonia oxidation, The sewage enters the anammox area from the nitrite accumulation area through the phosphorus removal filler. The phosphorus removal filler is alkali-modified sponge iron, which can be used as an oxygen scavenger to absorb part of the oxygen, and can also be used as a phosphorus removal filler to adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com