Porphyrin conjugated polymer bridged by pincerlike complex, synthetic method and application

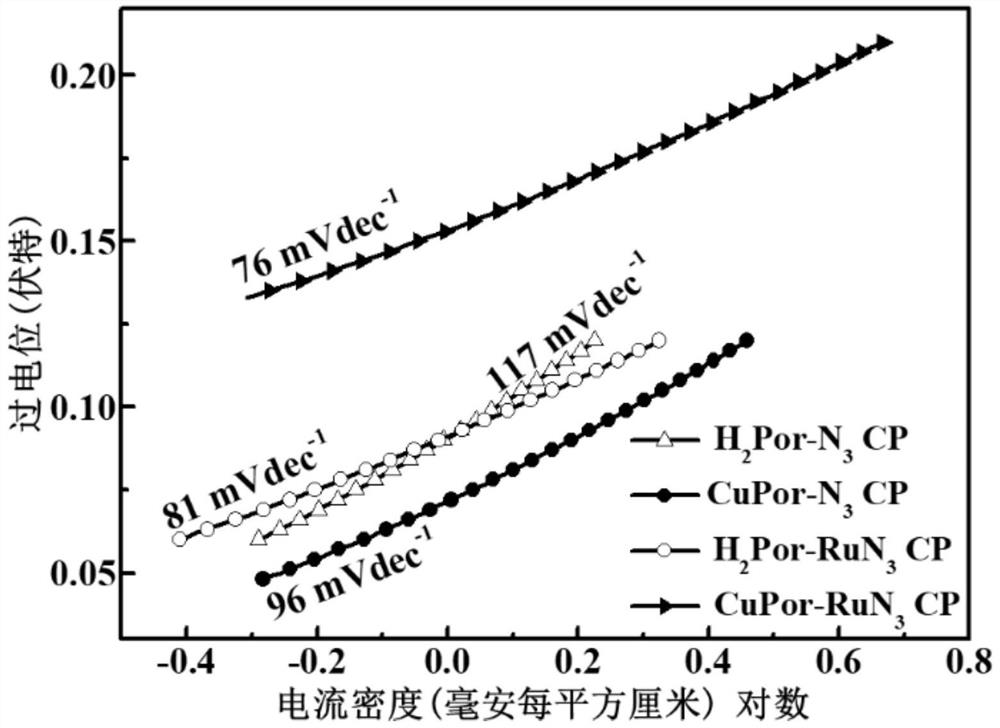

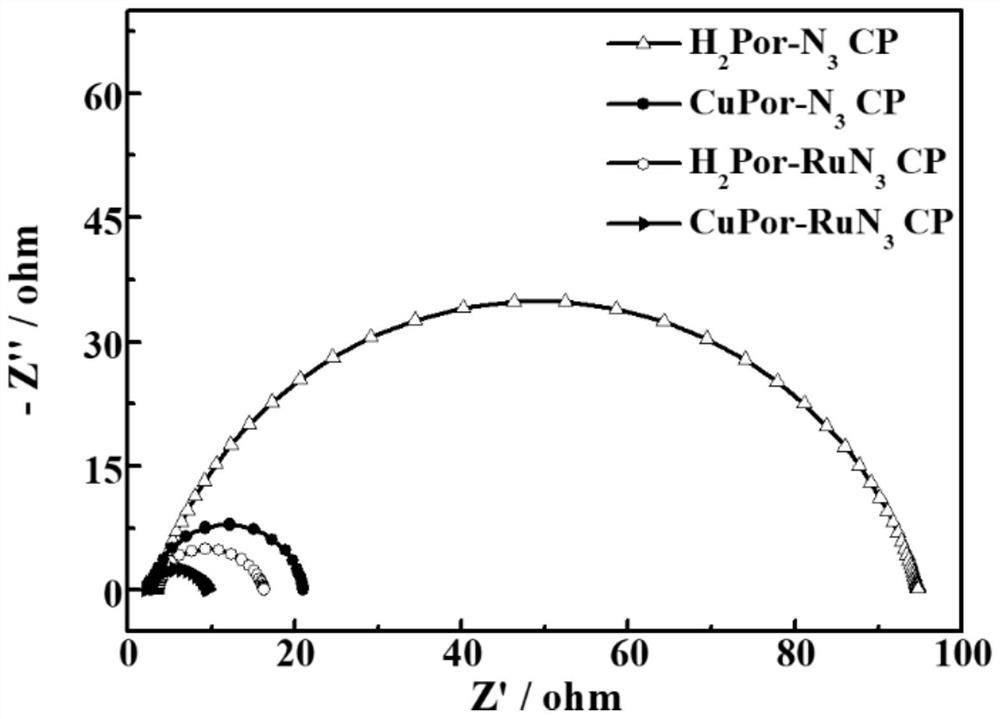

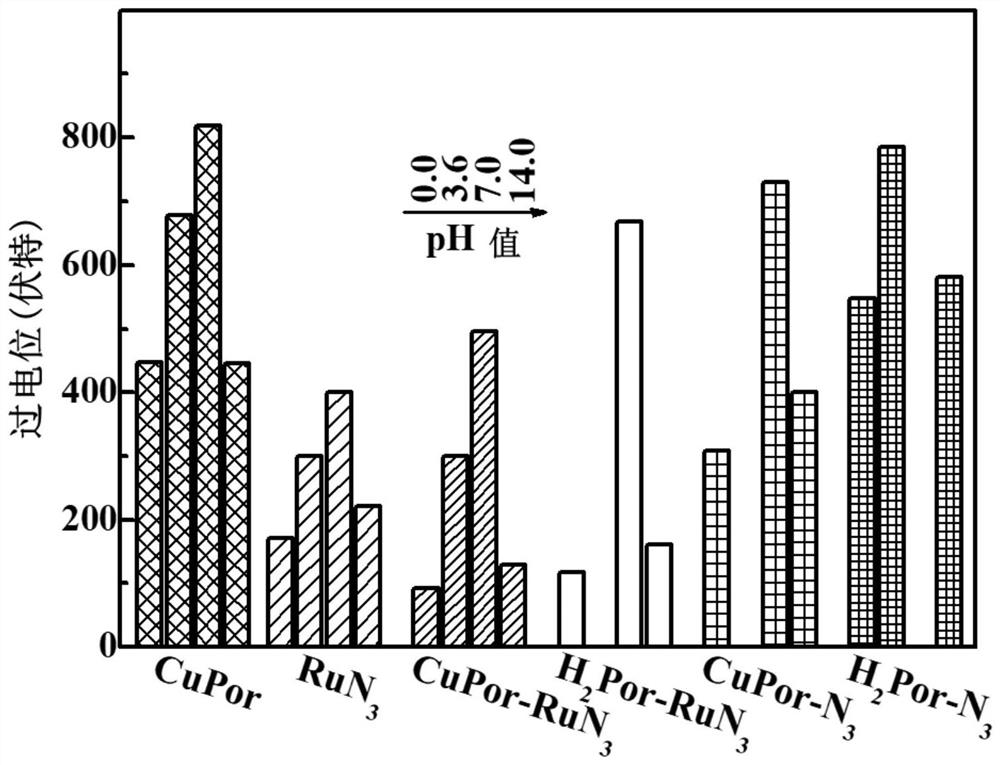

A technology of conjugated polymer and synthesis method, which is applied in the direction of electrolysis components, electrolysis process, electrodes, etc., to achieve the effect of good hydrogen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] M was synthesized using the above synthetic route for conjugated polymers 1 Por-M 2 N 3 CP, M 1 =H 2 , M 2 = Ru, the product is labeled H 2 Por-RuN 3 CP.

[0049] Proceed as follows:

[0050] Add H to the sealed tube 2 Por (17.4mg) and RuN 3 (28.6mg), then put into a 1:1 volume ratio of o-dichlorobenzene-n-butanol mixed solvent (1.0mL), ultrasonic for 20 minutes, then add 6M acetic acid (0.1mL), after three freeze-pump-thaw cycles Afterwards, the tube was flame-sealed and reacted at 120° C. for 72 hours. The product was filtered, washed with methanol and dichloromethane, and extracted by Soxhlet for 24 hours, and finally vacuum-dried to obtain the conjugated polymer (H 2 Por-RuN 3 CP).

Embodiment 2

[0052] M was synthesized using the above synthetic route for conjugated polymers 1 Por-M 2 N 3 CP; M 1 = Cu, no M 2 When , the product is labeled as CuPor-N 3 CP.

[0053] Proceed as follows:

[0054] In a sealed tube add CuPor (18.9mg) and N 3 (16.4mg), then put it into a 1:1 volume ratio of o-dichlorobenzene-n-butanol mixed solvent (1.0mL), sonicate for 20 minutes, then add 6M acetic acid (0.1mL), and freeze-pump-thaw three times Afterwards, the tube was flame-sealed and reacted at 120° C. for 72 hours. The product was filtered, washed with methanol and dichloromethane, and extracted by Soxhlet for 24 hours, and finally dried in vacuum to obtain a conjugated polymer (CuPor-N 3 CP).

Embodiment 3

[0056] M was synthesized using the above synthetic route for conjugated polymers 1 Por-M 2 N 3 CPs; M 1 =H 2 , without M 2 , the product is labeled as H 2 Por-N 3 CP.

[0057] Proceed as follows:

[0058] Add H to the sealed tube 2 Por (17.4mg) and N 3 (16.4mg), then put it into a 1:1 volume ratio of o-dichlorobenzene-n-butanol mixed solvent (1.0mL), sonicate for 20 minutes, then add 6M acetic acid (0.1mL), and freeze-pump-thaw three times Afterwards, the tube was flame-sealed and reacted at 120° C. for 72 hours. The product was filtered, washed with methanol and dichloromethane, and extracted by Soxhlet for 24 hours, and finally vacuum-dried to obtain the conjugated polymer (H 2 Por-N 3 CP).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com